Heating device of red lead oxidizing furnace

A technology of oxidation furnace and heating device, which is applied in the direction of lead oxide, lead red, etc., can solve the problems of increased production cost, low efficiency, low production efficiency, etc., and achieve the effect of improving efficiency and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

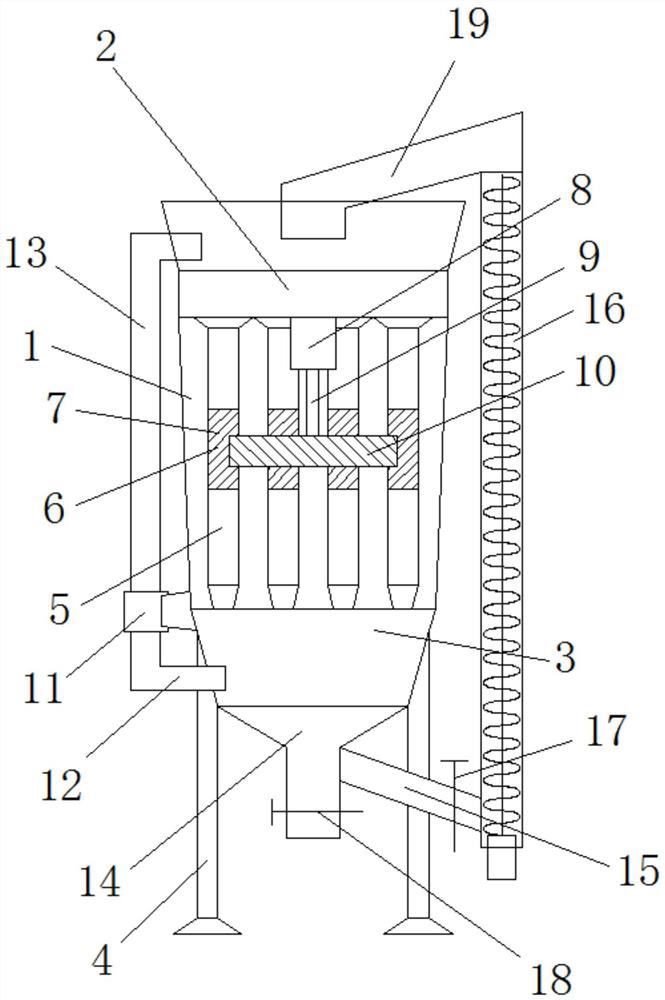

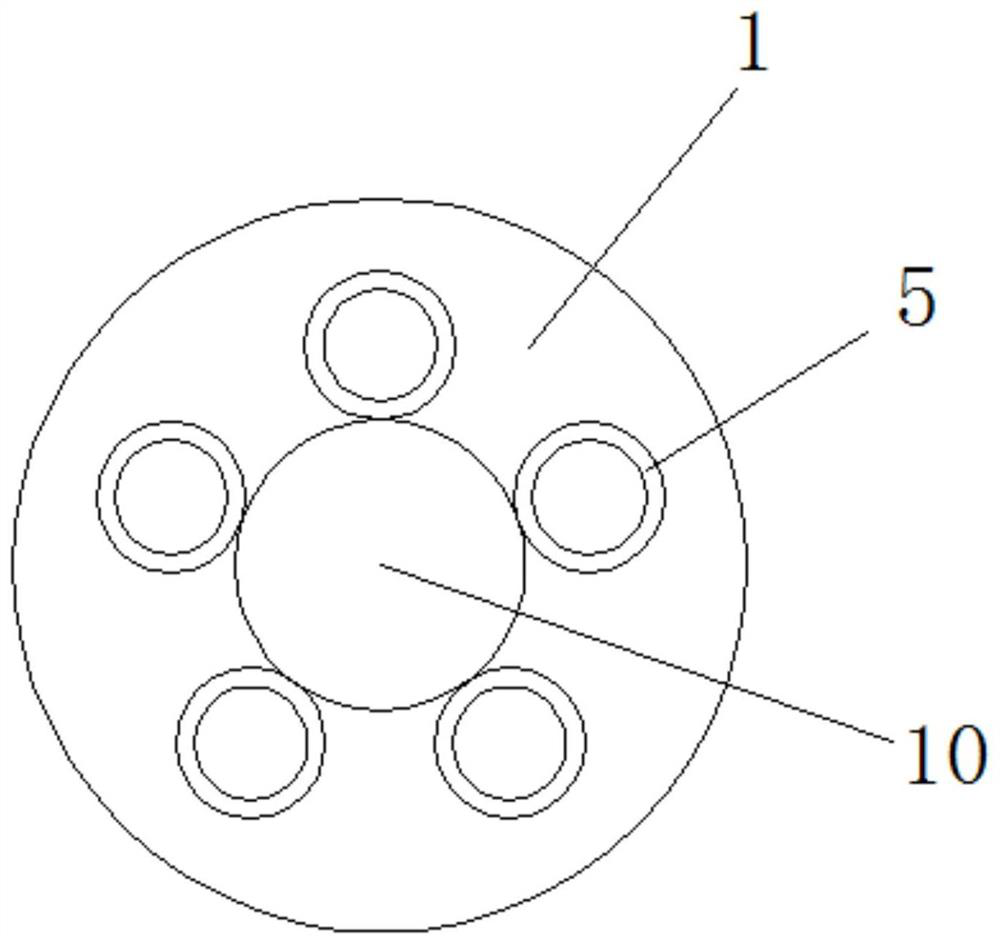

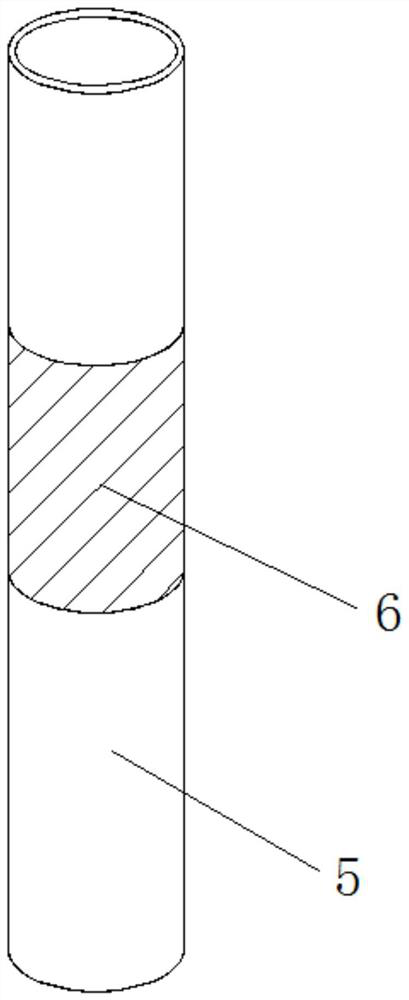

[0021] Embodiment 1: as Figure 1-4 As shown, a red lead oxidation furnace heating device comprises a thermal insulation bucket 1, a material bucket 2 is fixedly installed on the top of the thermal insulation bucket 1, and a feeding bin 3 is fixedly installed on the bottom of the thermal insulation bucket 1. A lower hopper 14 is fixedly installed at the bottom of the bin 3, and a number of distribution pipes 5 are fixedly connected between the material barrel 2 and the lower bin 3, and the distribution pipes 5 are distributed in the center of the inner cavity of the insulation barrel 1;

[0022] The side wall of described thermal insulation barrel 1 is fixedly equipped with hot air blower 11, and is fixedly connected with air inlet pipe 12 between the bottom of described hot air blower 11 and the side wall of lower material bin 3, and the top of described hot air blower 11 and material barrel A return air pipe 13 is fixedly connected between the side walls of 2;

[0023] The ...

Embodiment 2

[0027] Embodiment 2: as Figure 1-4 As shown, a red lead oxidation furnace heating device comprises a thermal insulation bucket 1, a material bucket 2 is fixedly installed on the top of the thermal insulation bucket 1, and a feeding bin 3 is fixedly installed on the bottom of the thermal insulation bucket 1. A lower hopper 14 is fixedly installed at the bottom of the bin 3, and a number of distribution pipes 5 are fixedly connected between the material barrel 2 and the lower bin 3, and the distribution pipes 5 are distributed in the center of the inner cavity of the insulation barrel 1;

[0028] The side wall of described thermal insulation barrel 1 is fixedly equipped with hot air blower 11, and is fixedly connected with air inlet pipe 12 between the bottom of described hot air blower 11 and the side wall of lower material bin 3, and the top of described hot air blower 11 and material barrel A return air pipe 13 is fixedly connected between the side walls of 2;

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com