Continuous deep dehydration all-in-one machine and deep dehydration process

A deep dewatering, integrated machine technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of reducing the amount of modification, intermittent operation of equipment, complicated auxiliary equipment, etc., to reduce intermediate The effect of conveying equipment, sludge concentration increase, and conveying power consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

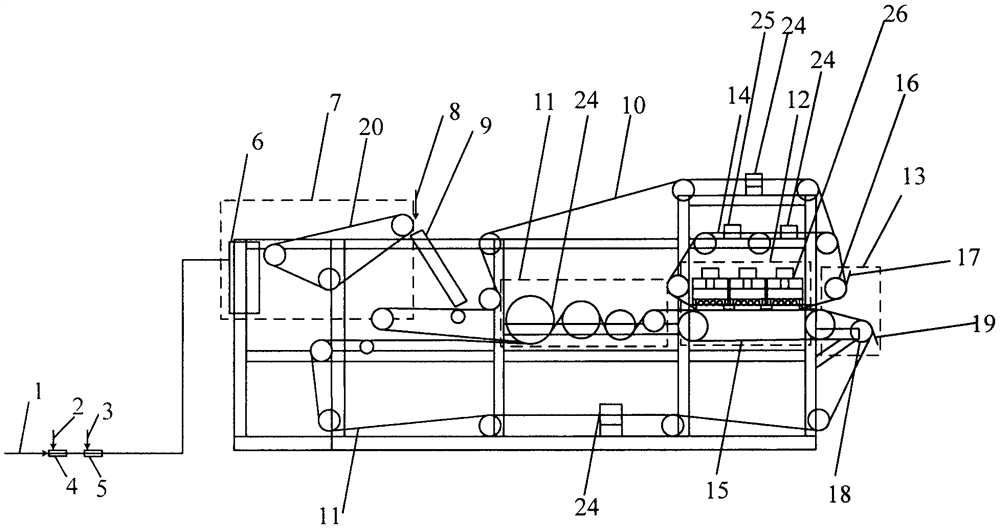

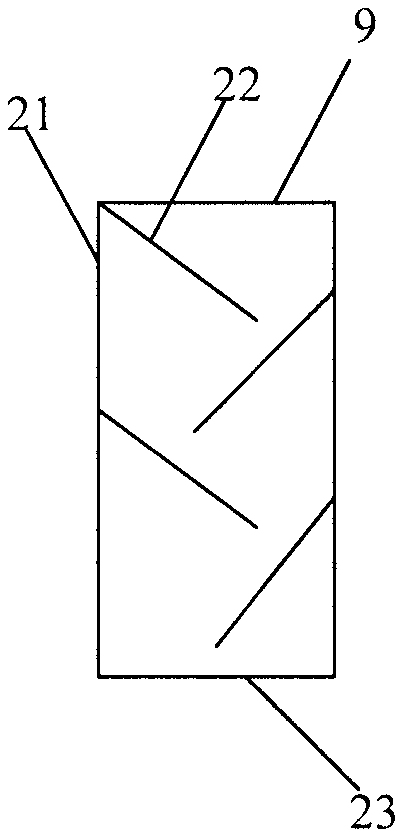

[0029] A continuous deep dehydration integrated machine and deep dehydration process, characterized in that: the continuous deep dehydration integrated machine is mainly composed of a concentration area 7, a non-powered mixer 9, a pre-pressing area 11, a pressing area 12, and a discharge area 13 Composition, the described enrichment zone 7 is made up of dynamic mixer 6 and concentrated dehydrator 20; Described unpowered mixer 9 is mainly made up of tank body 21, baffle plate 22 and screen 23; Said pre-compression zone 11 It is mainly composed of a dewatering roller body 24, an upper filter screen 10 and a lower filter screen 11; ; The discharge area is mainly composed of an upper discharge roller 16, a lower discharge roller 18, an upper scraper 17, and a lower scraper 19; the sludge feed pipe 1 is provided with a pipeline static mixer 4 and a pipeline static mixer 5 Add medicament A at the 2nd dosing port of the pipeline static mixer 4, add medicament B at the 3rd dosing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com