Bio butanol co-digestion bio-ethanol production method

A bio-ethanol and bio-butanol technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of large total energy consumption and large sewage discharge, and achieve the saving of water for mixing, management cost saving, The effect of saving processing investment and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

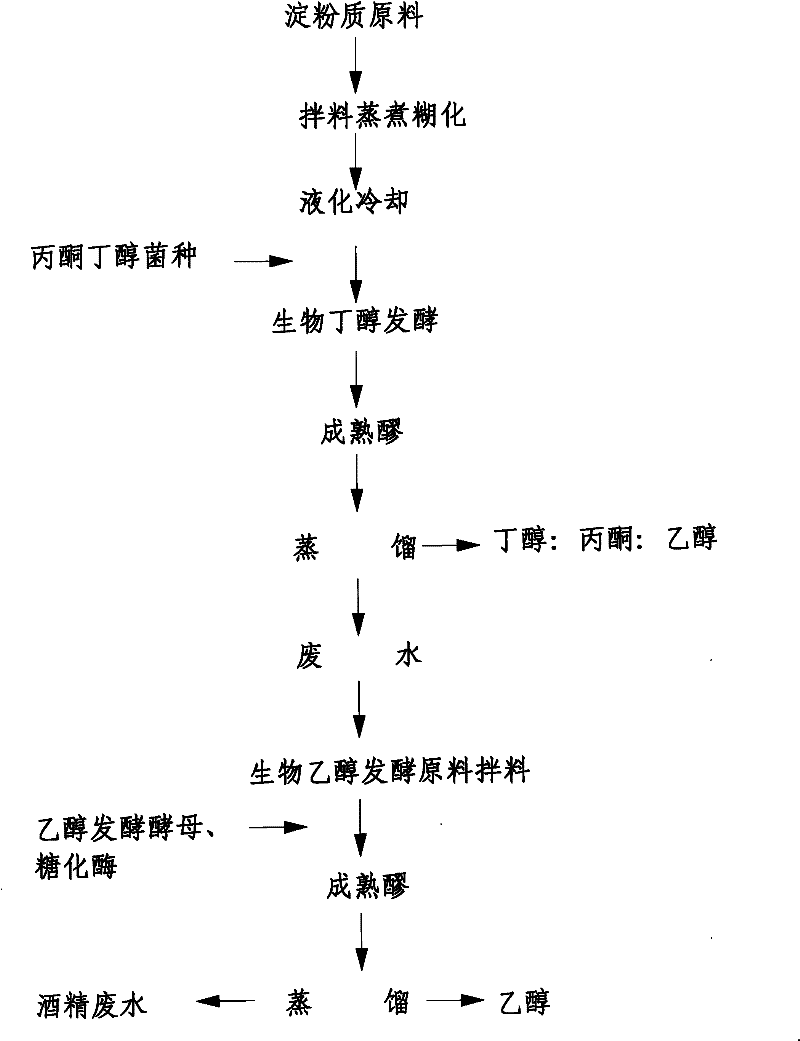

[0028] see figure 1 A method for producing bio-butanol combined fermentation of bio-ethanol, comprising the following steps: starchy raw materials are first mixed, cooked and gelatinized to form gelatinized mash containing 8-8.5% of starchy raw materials, and after liquefaction Cool, add acetone-butanol strains, and carry out bio-butanol fermentation. After the fermented mature mash is distilled and the total solvent is extracted (that is, butanol, acetone, ethanol is extracted), the distillation waste water is not discharged at all, and is used for bioethanol The raw material mixture produced is cooked and gelatinized to form gelatinized mash. After liquefaction and cooling, ethanol fermenting yeast and glucoamylase are added to carry out ethanol fermentation. The fermented mature mash is distilled to extract ethanol. Fermentation process wastewater treatment method. In the method of this embodiment, the wastewater after bio-butanol production does not need to be discharged,...

Embodiment 2

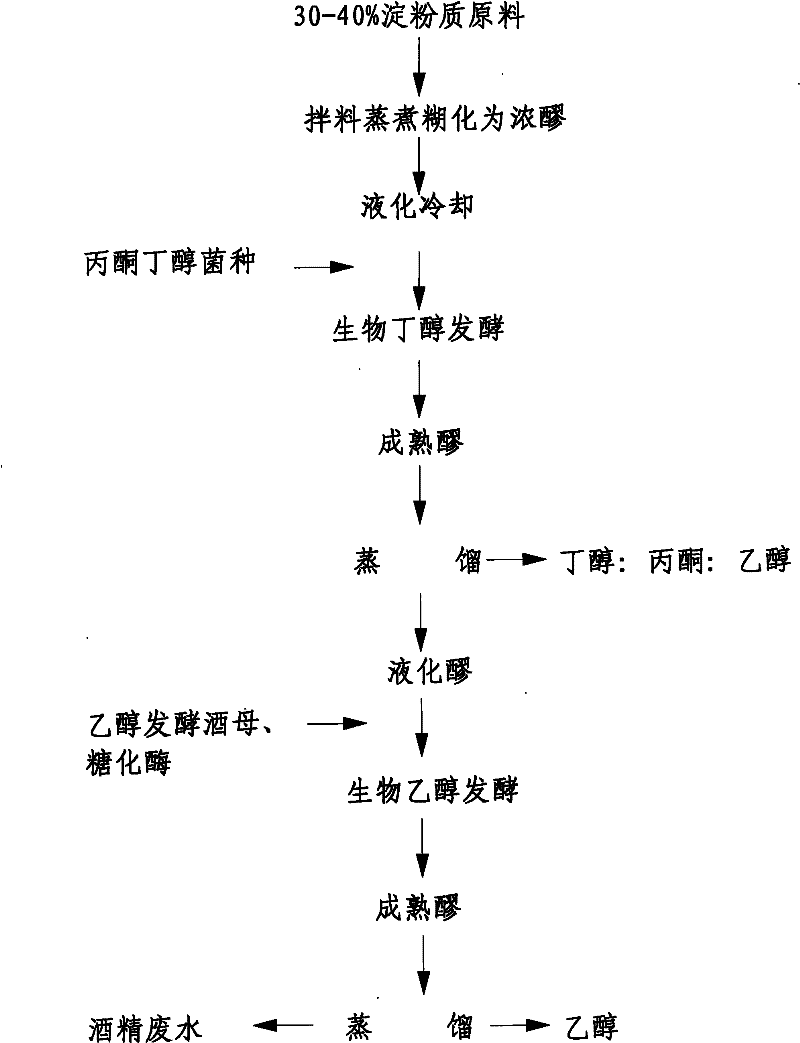

[0030] refer to figure 2, a method for producing bio-butanol combined fermentation bioethanol, comprising the following steps, starchy raw materials are first mixed, cooked and gelatinized to form gelatinized mash containing 30-40% of starchy raw materials, and after liquefaction Cool, add acetone-butanol strains, and carry out bio-butanol fermentation. After the fermentation, the mixed mature mash is distilled first, and after the total solvent is extracted (that is, butanol, acetone, and ethanol are extracted), the distillation wastewater is equivalent to the ethanol production process. The liquefied mash in it can be used for bioethanol production, adding ethanol fermented distiller's yeast and glucoamylase to carry out ethanol fermentation, and the fermented mature mash is distilled again to extract the ethanol, and the wastewater after distillation is treated according to the existing wastewater treatment method of ethanol fermentation process deal with.

Embodiment 3

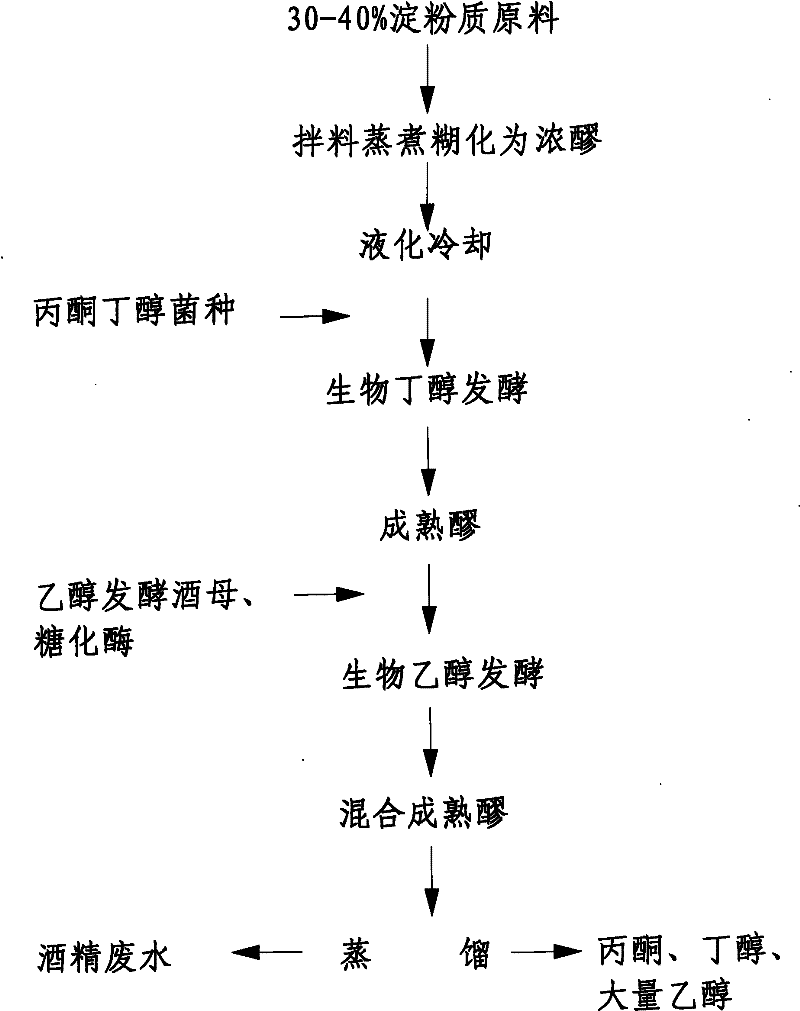

[0032] refer to image 3 , a method for producing bio-butanol combined fermentation bioethanol, comprising the following steps, starchy raw materials are first mixed, cooked and gelatinized to form gelatinized mash containing 30-40% of starchy raw materials, and after liquefaction Cool, add acetone-butanol strains, and carry out bio-butanol fermentation. The mature mash after fermentation is directly used for bioethanol production without distillation, and the added weight accounts for 0.5-1.5% (w / v) active dry yeast for ethanol fermentation or 5-30% (v / v) by volume ratio (v / v) of distiller's yeast for ethanol fermentation expanded through activation treatment and 100-200 units / gram of raw material glucoamylase to carry out ethanol Fermentation, the fermented mature mash is distilled to obtain acetone, butanol and ethanol products, because there is no need to carry out two distillations as in Examples 1 and 2, saving distillation steam. The wastewater after distillation is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com