Preparation method of hole plugging mud ball suitable for industrial silicon smelting silicon discharging

An industrial silicon and hole-blocking technology, which is applied in the direction of chemical instruments and methods, applications, silicon compounds, etc., can solve problems such as leakage, secondary pollution of products, and product degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

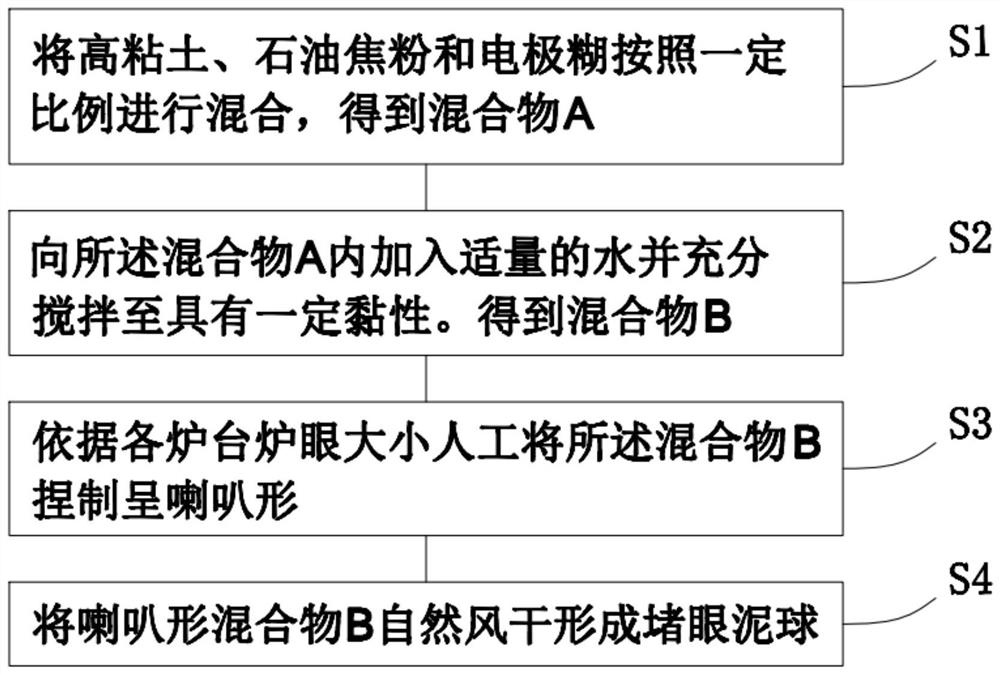

[0020] Please refer to figure 1 , figure 1 It is a flowchart of a preferred embodiment of the method for preparing eye plugging mud balls suitable for industrial silicon smelting to produce silicon provided by the present invention. A method for preparing eye plugging mud balls suitable for industrial silicon smelting to produce silicon comprises the following steps:

[0021] S1: Mix high clay, petroleum coke powder and electrode paste according to a certain ratio to obtain mixture A;

[0022] S2: Add an appropriate amount of water into the mixture A and stir well until it has a certain viscosity. mixture B is obtained;

[0023] S3: Manually knead the mixture B into a trumpet shape according to the size of the furnace holes of each furnace;

[0024] S4: The trumpet-shaped mixture B is naturally air-dried to form eye plugging mud balls.

[0025] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com