Modified peach gum paste for silk fabric acid dye printing and its preparation method and application

A technology of acid dyes and peach gum, which is applied in dyeing, textiles and papermaking, etc., can solve the problems of inability to disperse chemical additives evenly, limit the application of peach gum, and prevent peach gum from forming a paste, and achieve color fastness to soaping High grade, high color fastness to dry rubbing, not easy to paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

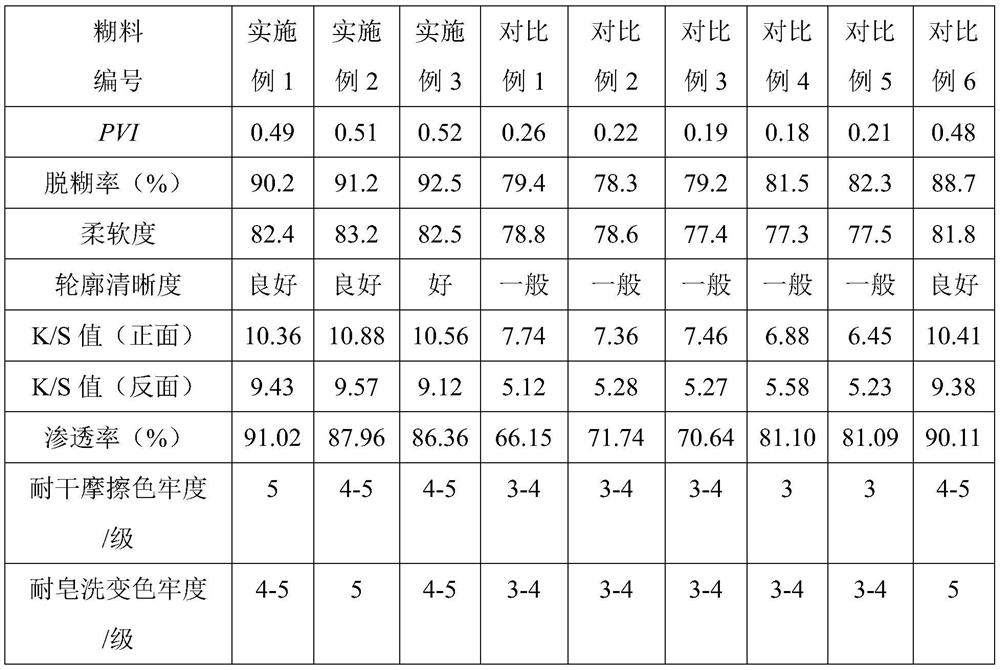

Examples

Embodiment 1

[0025] The preparation method of the modified peach gum paste printed with acid dyes on silk fabrics, the concrete method comprises the following steps:

[0026] (1) take by weighing 10g peach gum, be dissolved in the reactor that is housed with 150mL 3wt% NaOH aqueous solution, stir and dissolve at normal temperature; take by weighing 0.4g chloroacetic acid and add in the reactor, react at 65 ℃; add after the reaction finishes Distilled water, cooled, and adjusted the pH value to 7.5 with 5wt% hydrochloric acid to obtain a reaction solution of carboxymethyl peach gum.

[0027] (2) 1 g of sodium sulfite, 3 mL of 4wt% H 2 SO 4 React with 150 mL of the carboxymethyl peach gum reaction solution obtained in step (1), the reaction temperature is: 65° C., and the reaction time is: 7 hours. After the reaction, adjust the pH value to 7.5 with 25wt% NaOH aqueous solution to obtain modified solution.

[0028] (3) 1 g of epichlorohydrin was reacted with 150 mL of the modified solution...

Embodiment 2

[0031] The preparation method of the modified peach gum paste printed with acid dyes on silk fabrics, the concrete method comprises the following steps:

[0032] (1) take by weighing 8g peach gum, be dissolved in the reactor that is housed with 100mL 2wt% NaOH aqueous solution, stir and dissolve at normal temperature; take by weighing 0.24g chloroacetic acid and add in the reactor, react at 60 ℃; add after the reaction finishes Distilled water, cooled, and adjusted the pH value to 7 with 4wt% hydrochloric acid to obtain a carboxymethyl peach gum reaction solution.

[0033] (2) 1 g of sodium sulfite, 2 mL of 3wt% H 2 SO 4 React with 100 mL of the carboxymethyl peach gum reaction solution obtained in step (1), the reaction temperature is: 60 ° C, the reaction time is: 6 hours, after the reaction is completed, adjust the pH value to 7 with 20wt% NaOH aqueous solution to obtain modified solution.

[0034](3) react 1 g of epichlorohydrin with 100 mL of the modified solution obta...

Embodiment 3

[0037] The preparation method of the modified peach gum paste printed with acid dyes on silk fabrics, the concrete method comprises the following steps:

[0038] (1) take by weighing 12g peach gum, be dissolved in the reactor that is housed with 200mL 4wt% NaOH aqueous solution, stir and dissolve at normal temperature; take by weighing 0.6g chloroacetic acid and add it in the reactor, and react at 70 ℃; add after the reaction finishes Distilled water, cooled, and adjusted the pH value to 8 with 6wt% hydrochloric acid to obtain a carboxymethyl peach gum reaction solution.

[0039] (2) 1 g of sodium sulfite, 4 mL of 5wt% H 2 SO 4 React with 200 mL of the carboxymethyl peach gum reaction solution obtained in step (1), the reaction temperature is: 70 ° C, the reaction time is: 8 hours, after the reaction is completed, adjust the pH value to 8 with 30wt% NaOH aqueous solution to obtain modified solution.

[0040] (3) 1g of epichlorohydrin was reacted with 200mL of the modified s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com