Polyvinyl chloride composite cable insulating material and preparation method and application thereof

A composite cable and polyvinyl chloride technology, applied in the field of cable insulation materials, can solve the problems of poor friction resistance, scratch resistance, short service life of cable materials, poor insulation resistance, etc., achieve excellent flame retardancy, reduce surface Friction coefficient, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The embodiment of the present invention also provides a preparation method of polyvinyl chloride composite cable insulation material, comprising the following steps:

[0042] S10. Obtain the polyvinyl chloride resin, plasticizer, environmental stabilizer, filler, environmental flame retardant, pre-crosslinking agent P95 and silicone masterbatch of formula quantity;

[0043] S20. Add the polyvinyl chloride resin, the plasticizer, the environmentally friendly stabilizer, the filler, the environmentally friendly flame retardant, the pre-crosslinking agent P95 and the silicone masterbatch to In the mixer, carry out mixing treatment, obtain mixed product;

[0044] S30. Transfer the mixed product to a granulator, perform plasticization and granulation, and cool to obtain a polyvinyl chloride composite cable insulation material.

[0045] The preparation method of the polyvinyl chloride composite cable insulation material provided by the embodiment of the present invention obt...

Embodiment 1

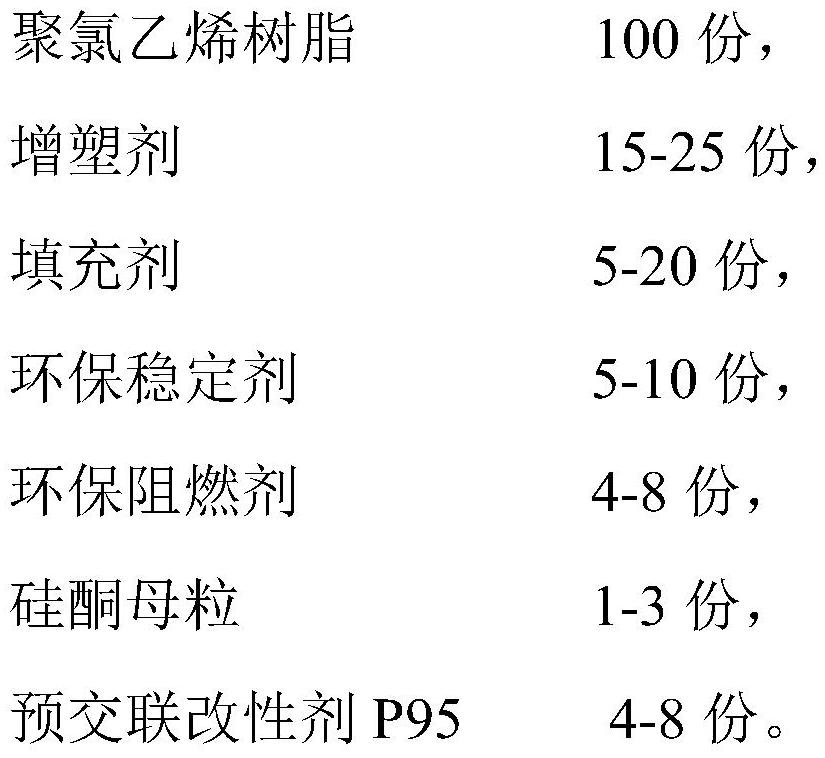

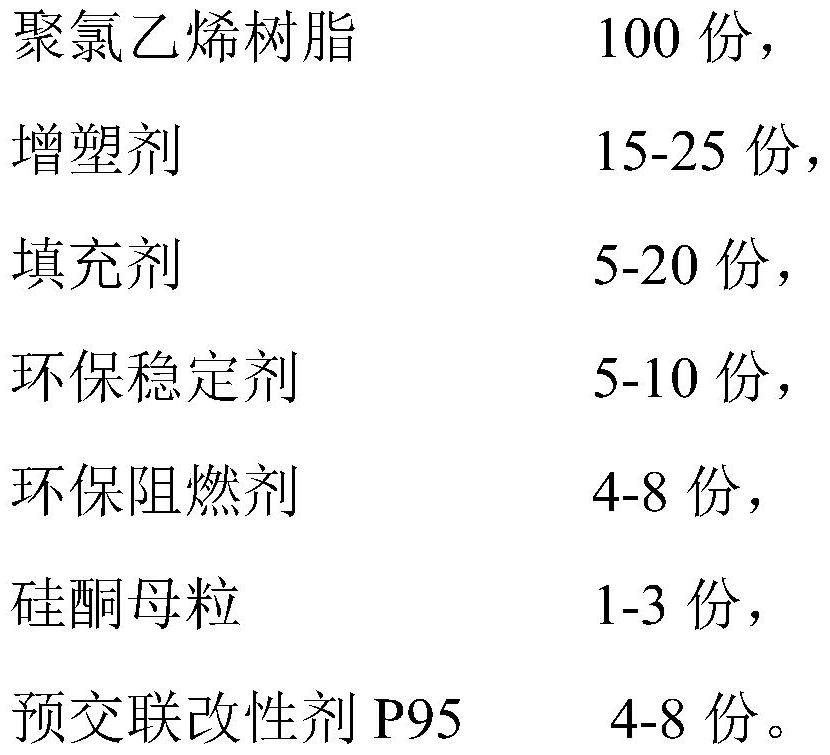

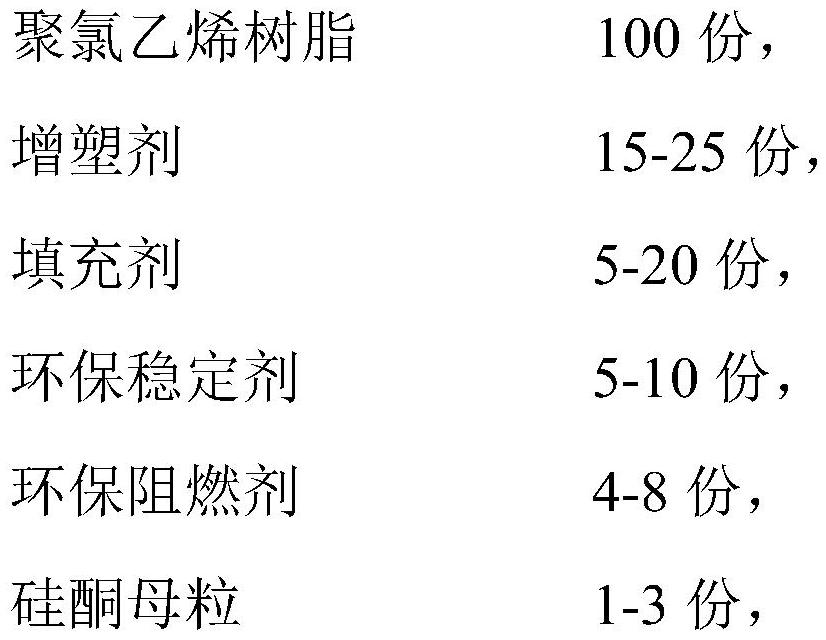

[0057] A polyvinyl chloride composite cable insulation material, comprising the following raw material components in parts by weight:

[0058]

[0059]

[0060] Among them, the polyvinyl chloride resin used is a polyvinyl chloride resin with a polymerization degree of 1300; the plasticizer used is TOTM or TINTM; the filler used is nano-calcium carbonate whose surface has been treated with silane; the stabilizer used is a calcium-zinc composite stabilizer .

[0061] The polyvinyl chloride composite cable insulation material is prepared through the following steps:

[0062] S10. Obtain the polyvinyl chloride resin, plasticizer, environment-friendly stabilizer, filler, environment-friendly flame retardant, pre-crosslinking agent P95 and silicone masterbatch of the above formula quantity;

[0063] S20. Add the polyvinyl chloride resin in the formula amount to the mixer, and add 70% to 80% of the plasticizer in the formula amount to the mixer in batches and mix evenly during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com