Manufacturing method of recyclable environment-friendly organic paper

A manufacturing method and organic technology are applied in the field of making recyclable and reusable environmentally friendly organic paper, which can solve problems such as failure to reduce secondary pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. In the following description, a lot of specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, and those skilled in the art can do it without departing from the meaning of the present invention. By analogy, the present invention is therefore not limited to the specific examples disclosed below.

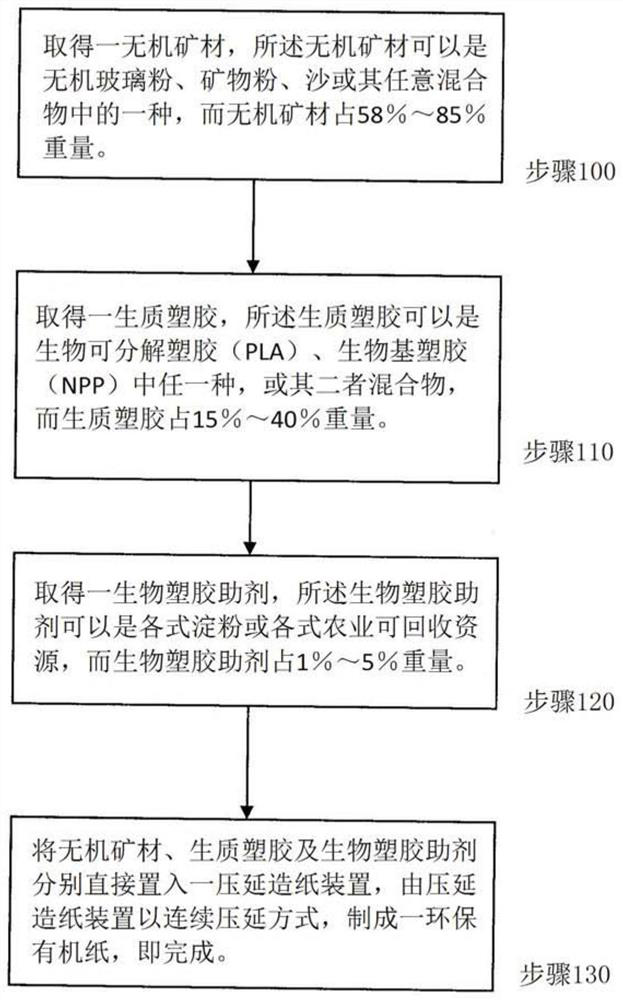

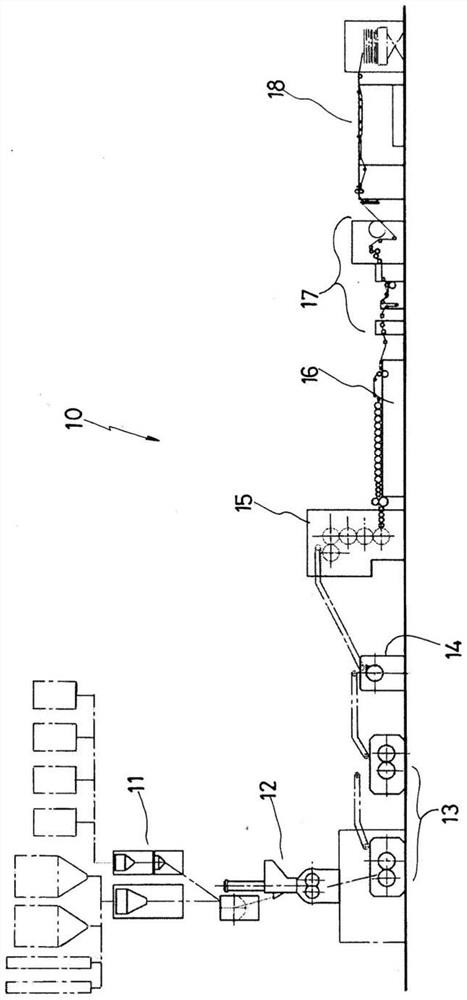

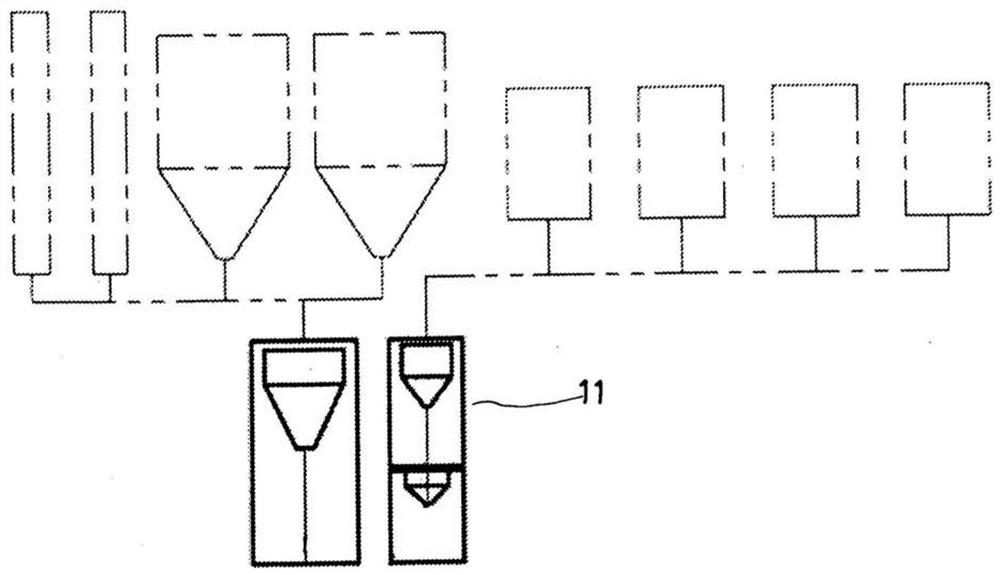

[0050] Please see first Figure 1 to Figure 10 Shown, the present invention discloses a kind of manufacturing method of recyclable environmental protection organic paper, and its manufacturing method comprises:

[0051]Step 100: Obtain an inorganic mineral material, which can be inorganic glass powder, mineral powder (such as: calcium carbonate, calcium carbonate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com