Safe anaerobic fermentation tank

An anaerobic fermentation tank, a safe technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, cleaning hollow objects, etc., can solve the problem of water shortage and increase the anaerobic fermentation time of organic matter , water vapor transmission speed slow down and other issues, to achieve the effect of maintaining water, reducing anaerobic fermentation time, and speeding up the transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

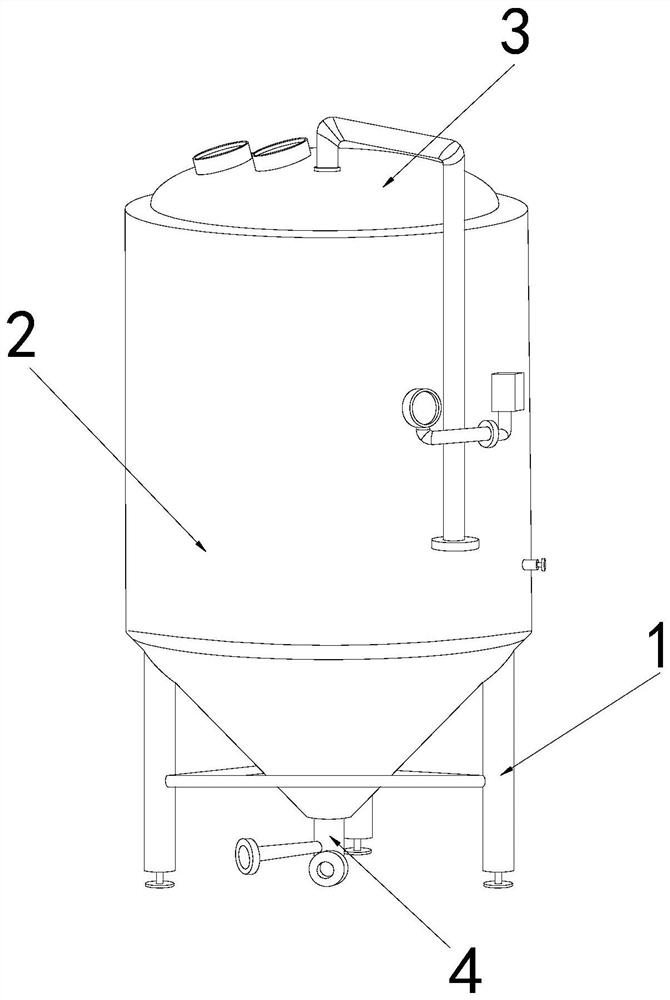

[0028] The invention provides a safe anaerobic fermentation tank, the structure of which includes a bracket 1, a tank body 2, a top cover 3, and a gas delivery pipe 4, the tank body 2 is vertically welded on the top of the bracket 1, and the top cover 3 is arranged on the top of the tank The center position of the top of the body 2, and the gas delivery pipe 4 is welded to the bottom of the tank body 2.

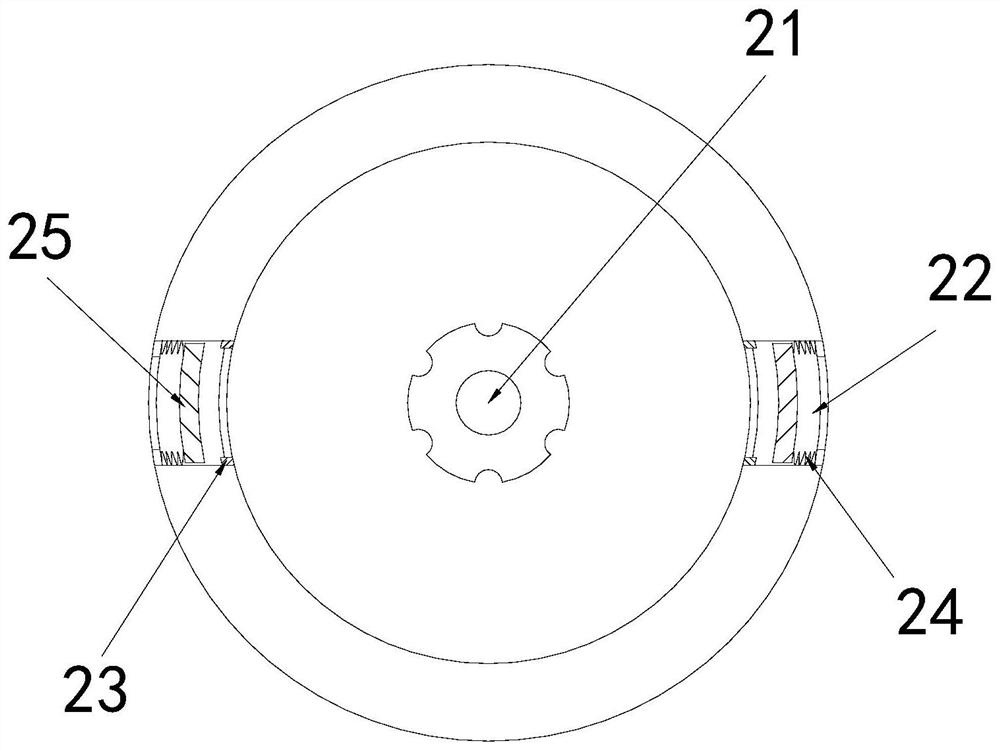

[0029] The tank body 2 is provided with a stirring rod 21, a steam pipe 22, a limit block 23, an elastic bar 24, and a moving block 25. The stirring rod 21 is installed in the middle of the tank body 2, and the steam pipe 22 runs through the tank body 2 The inner and outer walls on both sides of the middle part, the limiting block 23 is fixed on the inner wall of the steam pipe 22, the moving block 25 is arranged inside the steam pipe 22, and an elastic bar 24 is provided on the right side.

[0030] Wherein, the movi...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 8Shown:

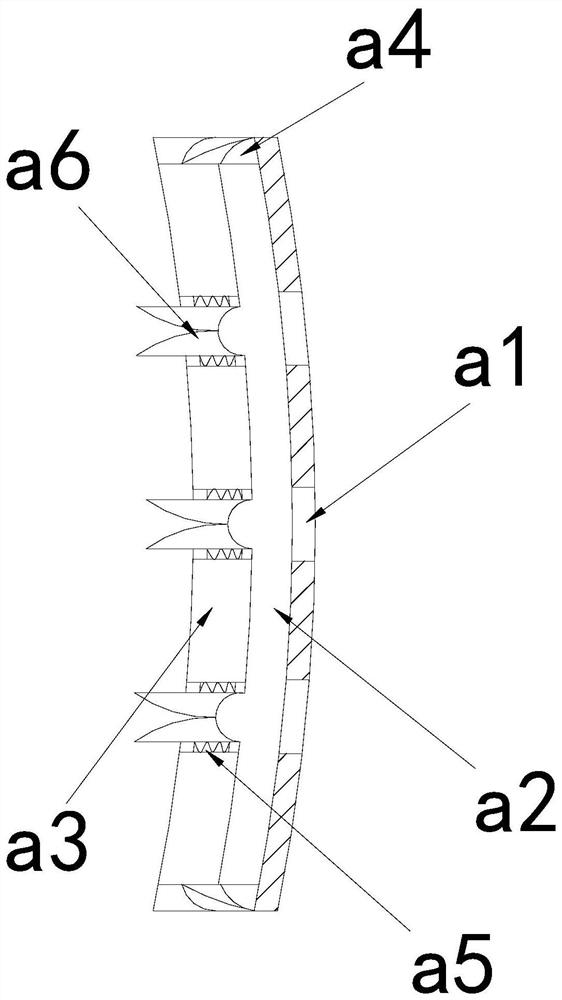

[0037] Wherein, the contact block a4 is provided with a connection block e1, a partition e2, an opening e3, a pole e4, and a cleaning block e5, the opening e3 runs through the top of the contact block a4, and the partition e2 is arranged inside the contact block a4, The connection block e1 is located between the inner bottom of the contact block a4 and the bottom surface of the partition e2, the support rod e4 is fixed on the top surface of the partition e2 through the opening e3, and the cleaning block e5 is installed on the top of the support rod e4. The top surface of the removal block e5 is an undulating surface, which is conducive to increasing the contact area with the inner wall of the steam pipe 22, speeding up the removal of the mixture on the inner wall of the steam pipe 22, and keeping the steam pipe 22 unblocked.

[0038] Wherein, the opening e3 is provided with a block r1, a baffle r2, and a spring r3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com