Tension-anchor type structural steel cantilever supporting operation scaffold combined system and construction method

A technology of cantilevered scaffolding and construction method, which is applied to the scaffolding supported by the building structure, the accessories of the scaffolding, the formwork/formwork/work frame, etc. problem, to achieve the effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

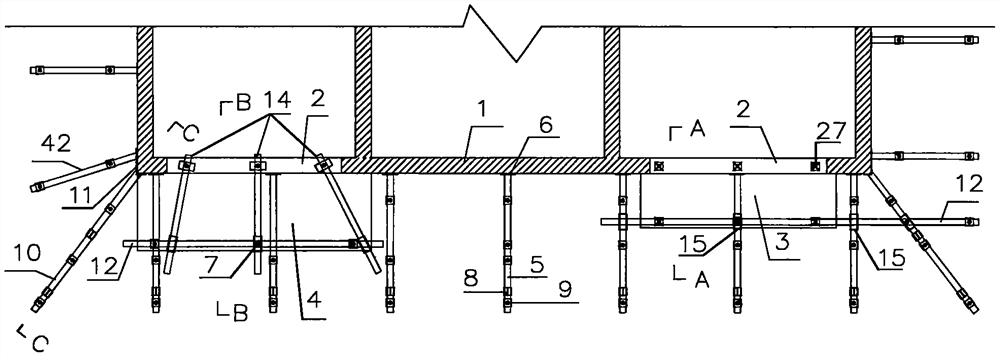

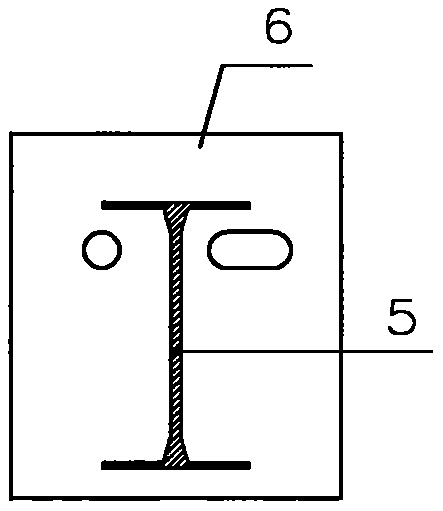

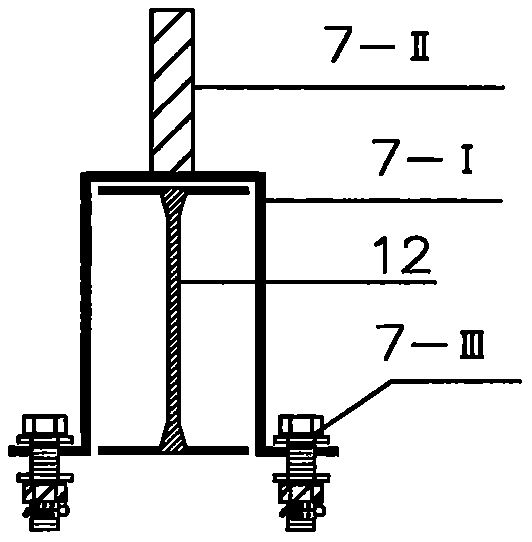

[0045] The working condition of this embodiment is the bay window part of the concrete structure, combined with Figure 1-Figure 12 Illustrate this embodiment, in this embodiment, a combination system and construction method of anchor-type steel cantilevered support work scaffolding, figure 1 It is a schematic diagram of the plane layout of the steel foundation and accessories, Figure 2 to Figure 11 Construct large mockups for each fitting, Figure 12It is a schematic diagram of the cross-sectional structure of A-A of this embodiment; by embedding the pre-embedded fixing device 16, it is pre-embedded to the designated position of the structure in advance (two I-beam anchorage positions are pre-embedded, and each flower basket tie rod upper structure hanging point One is pre-embedded, and one is pre-embedded at each position of the scaffolding wall parts), and the anchor end plate 6 is welded to the end of the I-beam main beam 5, and the high-strength bolts used in conjunctio...

Embodiment 2

[0047] In combination with embodiment 1 and Figure 13 Describe this embodiment, a combination system and construction method of an anchor-type steel cantilever support scaffolding operation involved in this embodiment. The advantage is that the I-steel support beam 14 is set at the position of the protruding balcony slab of the structure, the I-steel support beam is used to fix and the pole base device 13 is used, and the indoor proximal end of the I-steel support beam 14 is anchored in the lower part. The upper part of the floor or beam supported by the wall further supports the outdoor remote end of the I-beam support beam 14 on the main node of the scaffold pole 21 and the support cross bar 20. If the I-beam primary and secondary beams are connected by aluminum mold support If the I-shaped steel primary and secondary beams are fixed and the vertical pole base device 7 is used to lock the primary and secondary beams to each other, if the I-shaped steel primary and secondary...

Embodiment 3

[0049] In combination with embodiment 1 and Figure 14 Describe this embodiment, which involves an anchor-type steel cantilever support scaffold combination system and construction method in this embodiment. The difference of Example 1 is that the I-steel male corner beam 10 is welded to the I-steel male corner beam end plate 11, and is anchored to the male corner of the outer wall surface of the structure or the male corner of the beam side through a pre-embedded fixing device 16. position, the angle of the I-beam male angle beam is 45°~60°, which can be adjusted according to actual needs. Two detachable steel beam hanger plate devices 8 are arranged on the I-beam male angle beam 10. Set up a pre-embedded bolt fixing device on both sides of the external corner of the top outer wall and install the ring head bolts, and connect the two detachable steel beam lugs of the I-steel male corner beam 10 through the flower basket pull rod one after the other. The device 8 is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com