A leak-proof grout structure for concrete components

A technology for preventing grout leakage and concrete components, which is applied to the preparation of building components on site, building construction, and connection parts of formwork/formwork/work frame, etc. Problems such as misalignment of components, etc., to reduce slurry leakage, improve the ability to prevent slurry leakage, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

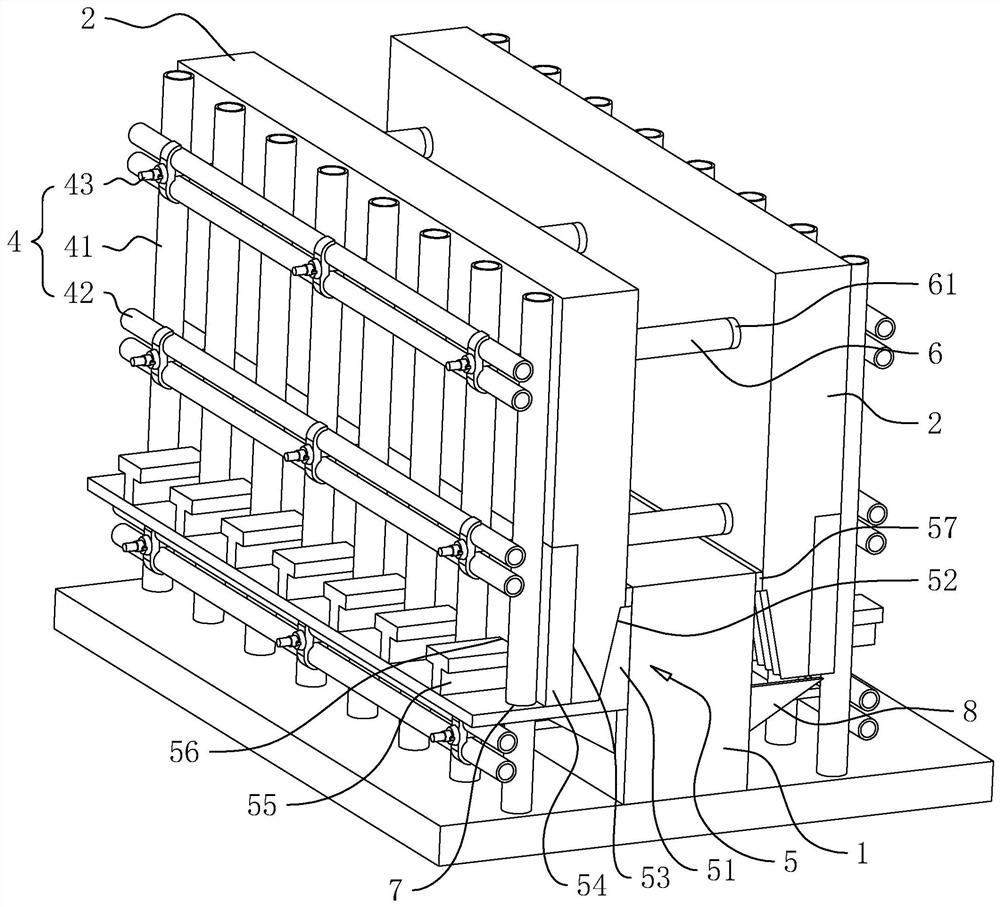

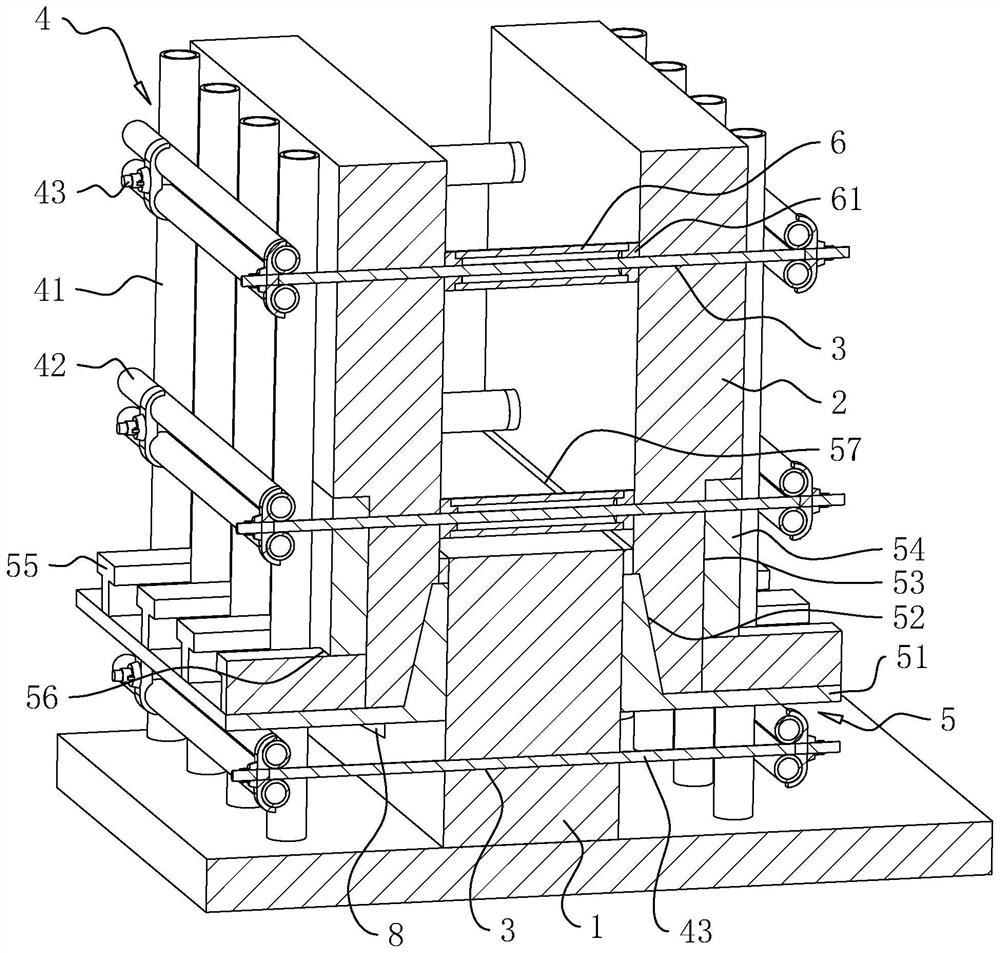

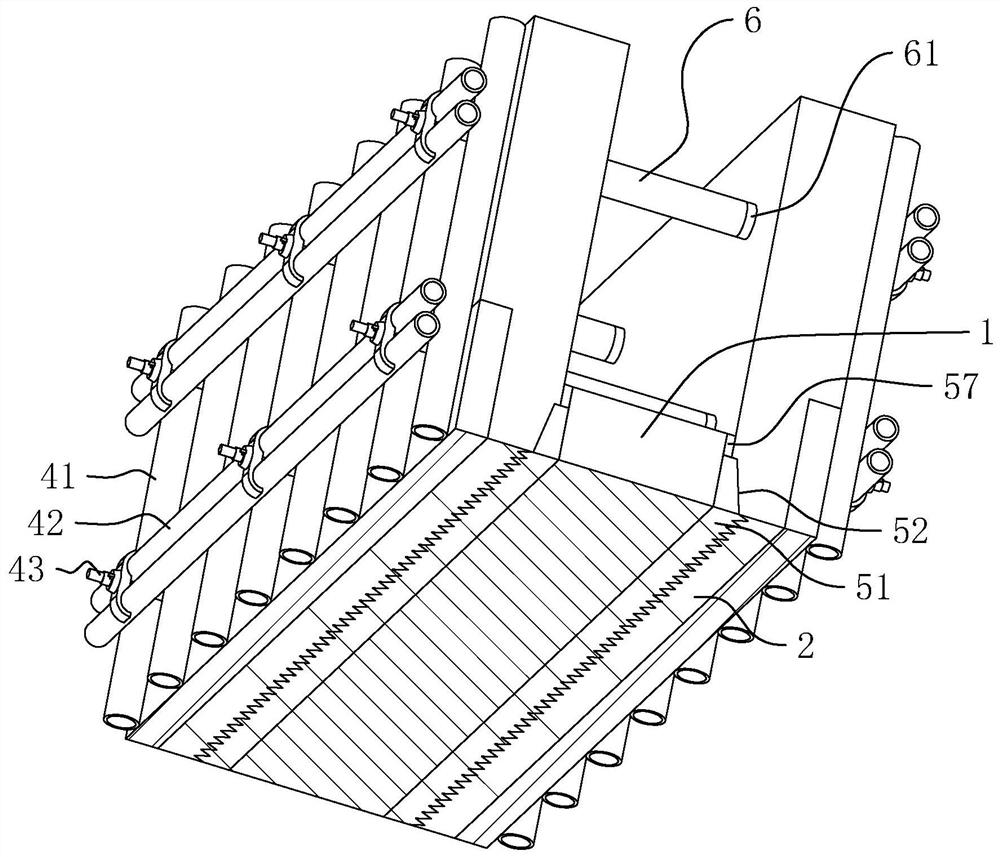

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] The embodiment of the application discloses a leak-proof grout structure of a concrete member. refer to figure 1 and figure 2 , the leak-proof slurry structure of the concrete member, including the base 1, the opposite formwork 2 is provided on both sides of the base 1, and the side of the lower end of the formwork 2 facing the base 1 is provided with a leak-proof assembly for sealing the gap between the formwork 2 and the base 1 5. A pair of templates 2 are provided with a number of relative reserved holes 3, and the base 1 is also provided with a number of reserved holes 3 passing through the base 1, and the axes of the reserved holes 3 on the base 1 are aligned with the reserved holes on the template 2. The 3 axes are parallel, and the fixing assembly 4 for fixing the template 2 on the base 1 is arranged between the reserved holes 3 .

[0037] The fixing assembly 4 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com