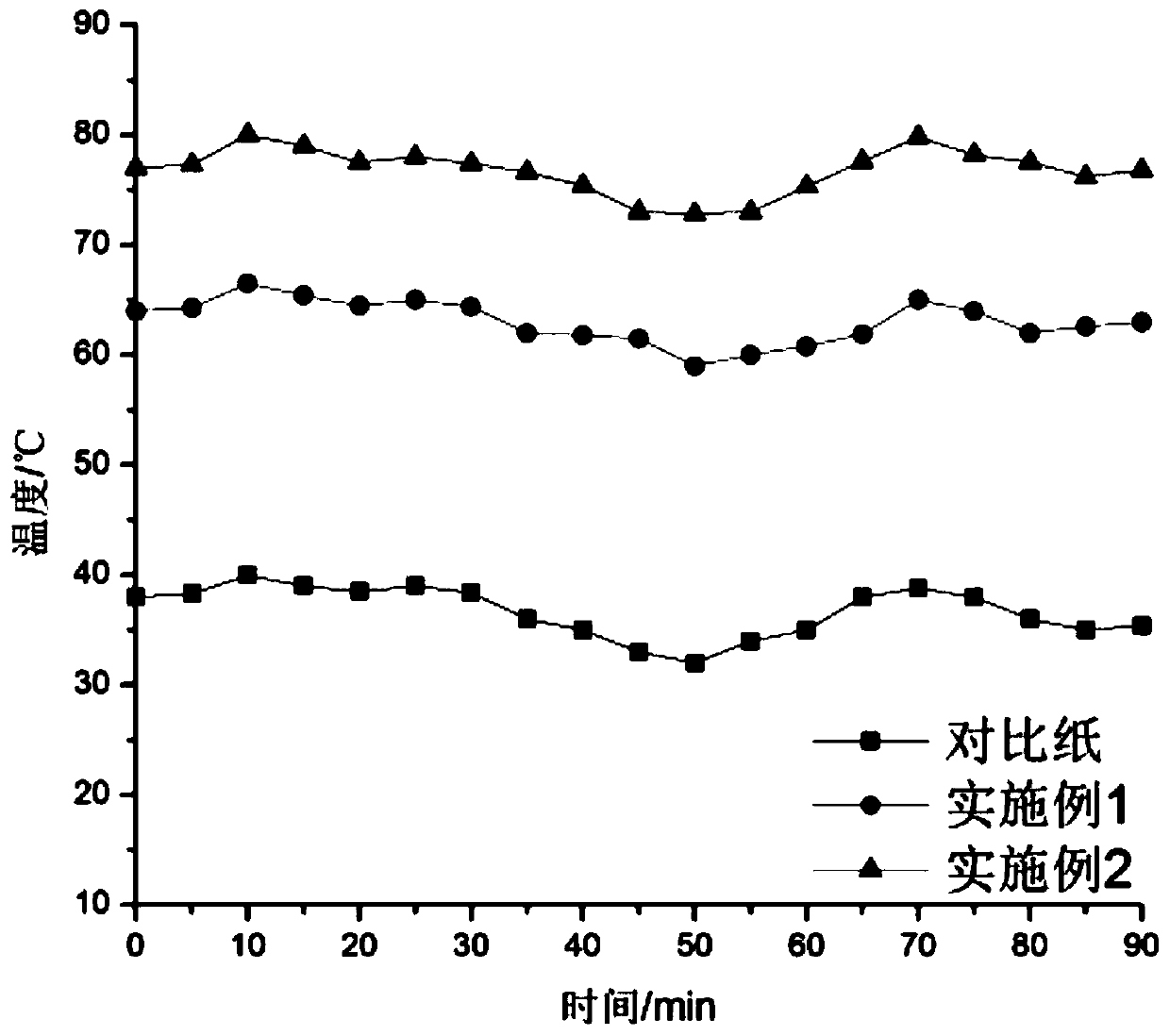

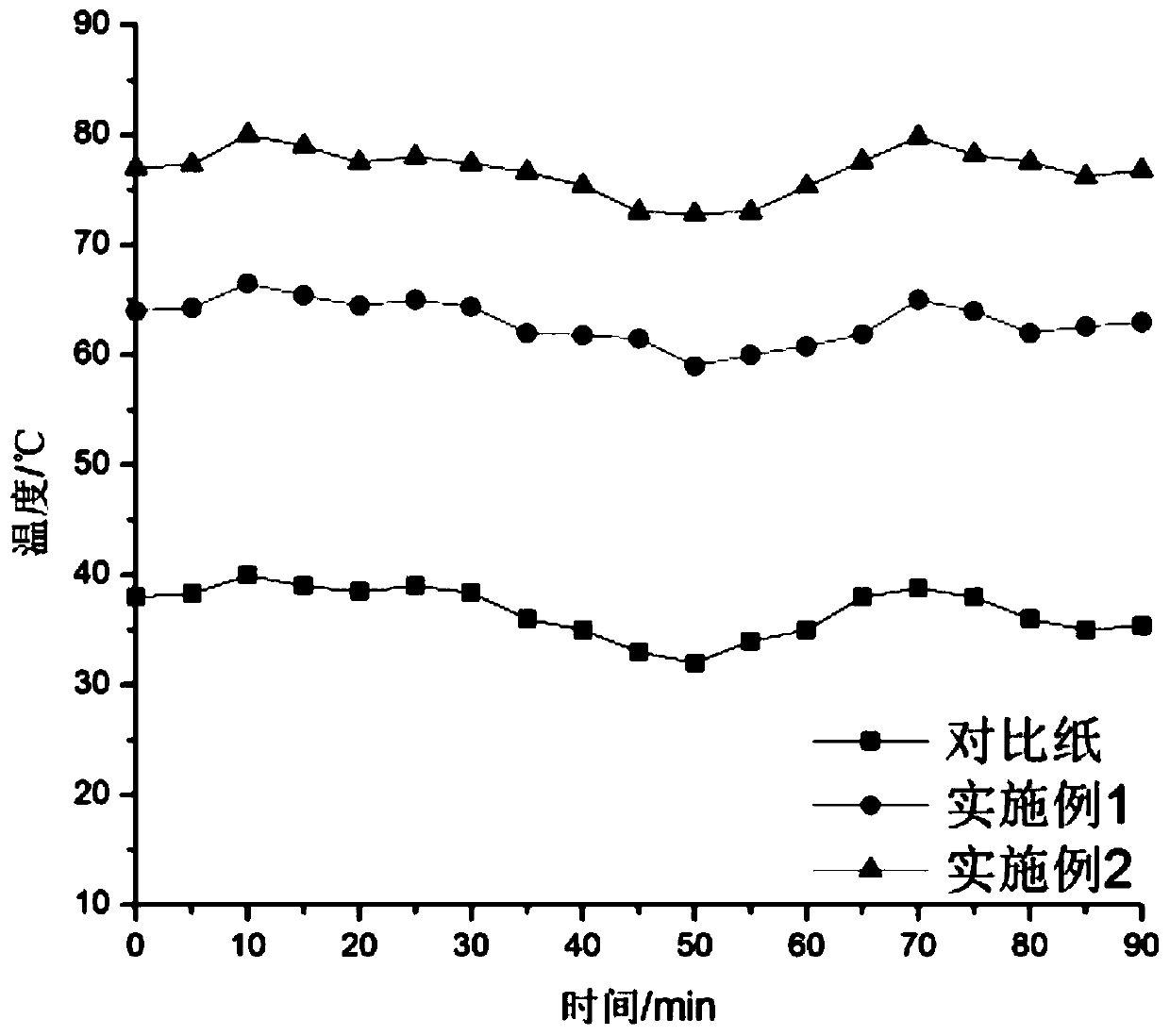

Preparation method for self-heating heat-storage heat-insulation paper

A thermal insulation paper and heat storage technology, which is applied in special paper, paper, papermaking, etc., can solve the problems of high cost and poor flexibility of sunlight thermal storage paper, and achieve the effects of low cost, improved light absorption capacity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment 1: The preparation method of the self-heating heat storage thermal insulation paper of this embodiment is carried out according to the following steps:

[0016] 1. Mix 5%-10% carbon black, 20%-30% zirconium carbide and 60%-75% alumina according to mass percentage to obtain a filler mixture;

[0017] 2. Add the retention aid and filler mixture to the pulp and mix evenly to obtain the paper material, which is then made and dried to obtain self-heating heat storage insulation paper; the mass of the filler mixture accounts for 5 of the dry weight of the solids in the paper material %~10%.

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the retention aid is polyethyleneimine and / or attapulgite; the others are the same as Embodiment 1.

specific Embodiment approach 3

[0019] Specific embodiment three: This embodiment is different from specific embodiment two in that the mass of polyethyleneimine accounts for 1% to 2% of the dry weight of the solid phase in the paper material, and the mass of attapulgite accounts for the solid phase in the paper material 2% to 3% of dry weight; others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com