Kitchen rubber sole and preparation method and secondary vulcanization process thereof

A technology of rubber soles and processes, applied in soles, footwear, applications, etc., can solve problems such as poor oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

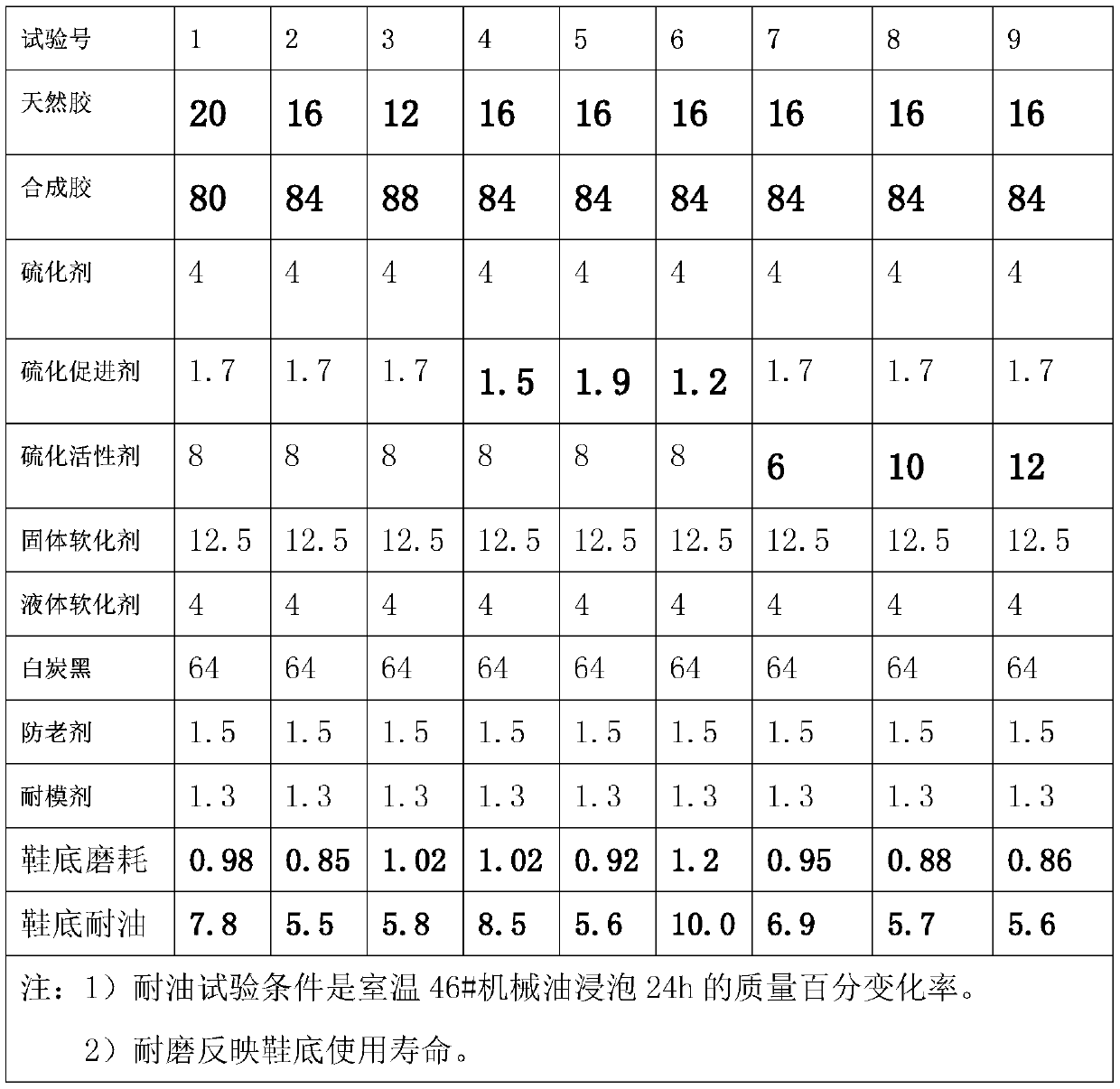

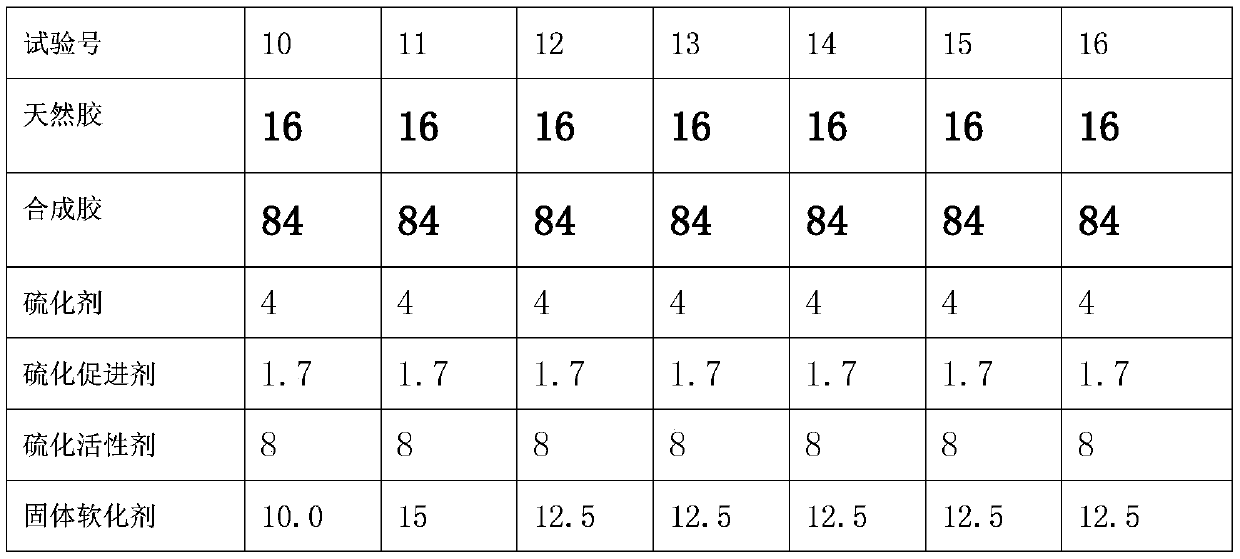

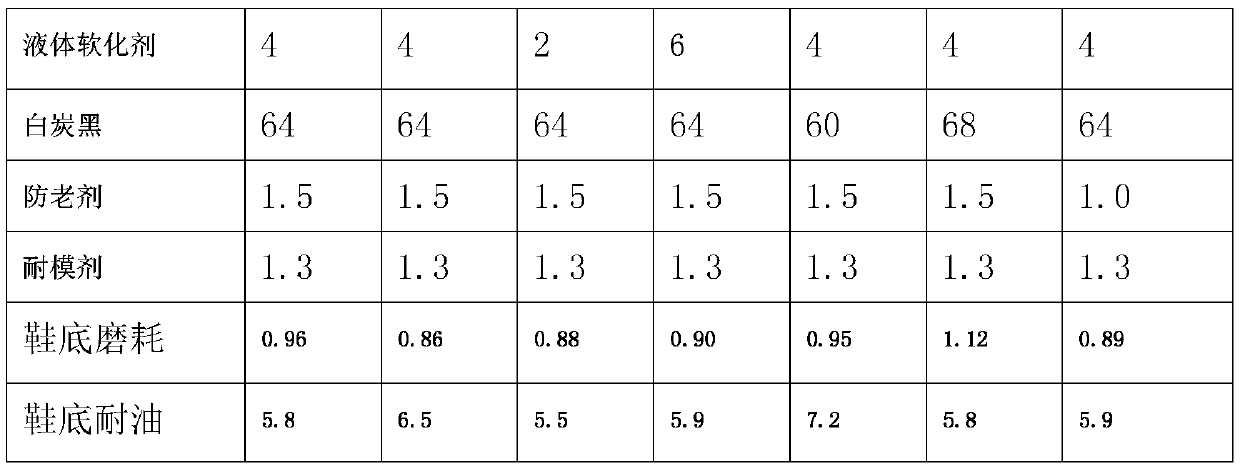

[0084] Formula example and preparation method of kitchen rubber sole:

[0085] 1) Formula: 16 parts of natural rubber, 84 parts of synthetic rubber, 4 parts of vulcanizing agent, 1.7 parts of vulcanization accelerator, 8 parts of vulcanization activator, 12.5 parts of solid softener, 4 parts of liquid softener, 64 parts of reinforcing agent and anti-aging agent 1.5 parts, 1.3 parts of anti-wear agent, 1.0 parts of coloring agent.

[0086] 2) The preparation method of kitchen rubber sole is as follows:

[0087] (1) Mastication: take the rubber and pass it on an open rubber mixer with a distance of 0 rolls, and refine it until the Vickers plasticity is 0.45-0.50 to obtain the plastication rubber;

[0088] (2) Ingredients: Coarse material is obtained by metering reinforcing agent; softener is obtained by putting liquid softener in an open barrel; vulcanization accelerator, vulcanization activator, anti-aging agent and wear-resistant agent, colorant, and solid softener are mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com