Roof sun panel and its installation method

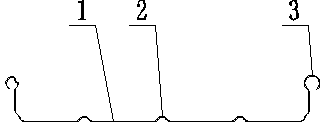

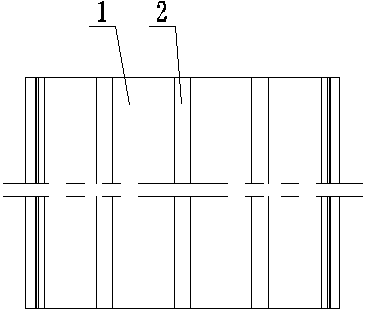

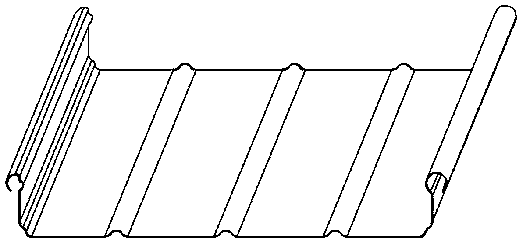

An installation method and technology of solar panels, which can be applied to roofs, roof covering layers, and roofs using flat/curved panels, etc., can solve the problems of deformation of solar panels, complex structure, and roof water seepage, and achieve the overall harmonious beauty and excellent performance of the roof. , the effect of enhancing the ability to resist external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]In January 2012, a large-scale enterprise in Liuzhou City, Guangxi, expanded the workshop, and adopted the roof of the roof sun panel installation workshop designed by the inventor. A heat insulation layer was installed on the roof below the sun panel, and a 0.3mm purlin was installed on the roof purlin 9. thick aluminum alloy bottom plate 12, on the upper surface of the aluminum alloy bottom plate 12, lay a glass wool heat insulation layer 11 with a single layer of aluminum foil, (the thickness of the heat insulation layer is compressed from 100mm to 65mm), and install it on the fixed seat 10 with screws 13 In fact, after 4 months of trial, the workshop completed and put into production has good lighting. When the weather is fine, it can provide daytime indoor lighting without conventional energy such as electricity, which not only saves a lot of energy, but also brings a healthy and comfortable working environment for indoor people. Little waste of resources and environ...

Embodiment 2

[0046] In February 2012, a university in Nanning City, Guangxi needed to build a wind and rain playground. The roof sun board designed by the inventor was used to install the roof of the playground. A heat insulation layer was installed on the roof below the sun board, and 0.8 Aluminum alloy bottom plate 12 with a thickness of 12mm, on the upper surface of the aluminum alloy bottom plate 12, lay a glass wool heat insulation layer 11 with a single layer of aluminum foil, (the thickness of the heat insulation layer is compressed from 100mm to 80mm), and install it on the fixing seat with screws 13 On October 10, after 3 months of probation, it was praised by the teachers and students of the school.

Embodiment 3

[0048] In January 2012, a gymnasium in Nanning City, Guangxi needed to rebuild the sports field. The roof sun panel designed by the inventor was used to install the roof of the sports field. A heat insulation layer was installed on the roof below the sun panel, and the roof purlin 9 was installed with a thickness of 0.6mm. The aluminum alloy base plate 12, on the upper surface of the aluminum alloy base plate 12, lay a glass wool heat insulation layer 11 with a single layer of aluminum foil (the thickness of the heat insulation layer is compressed from 100mm to 75mm), and install it on the fixing seat 10 with screws 13 , After 4 months of trials and tests of ups and downs, no water leakage occurred, which was praised by the leaders of the gymnasium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com