Clutch operating system and vehicle

An operating system and clutch technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of lack of closed-loop control, affecting the driving experience, and inability to adjust the speed and specific position of the release bearing, so as to improve the driving experience. , avoid turbulence, optimize the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

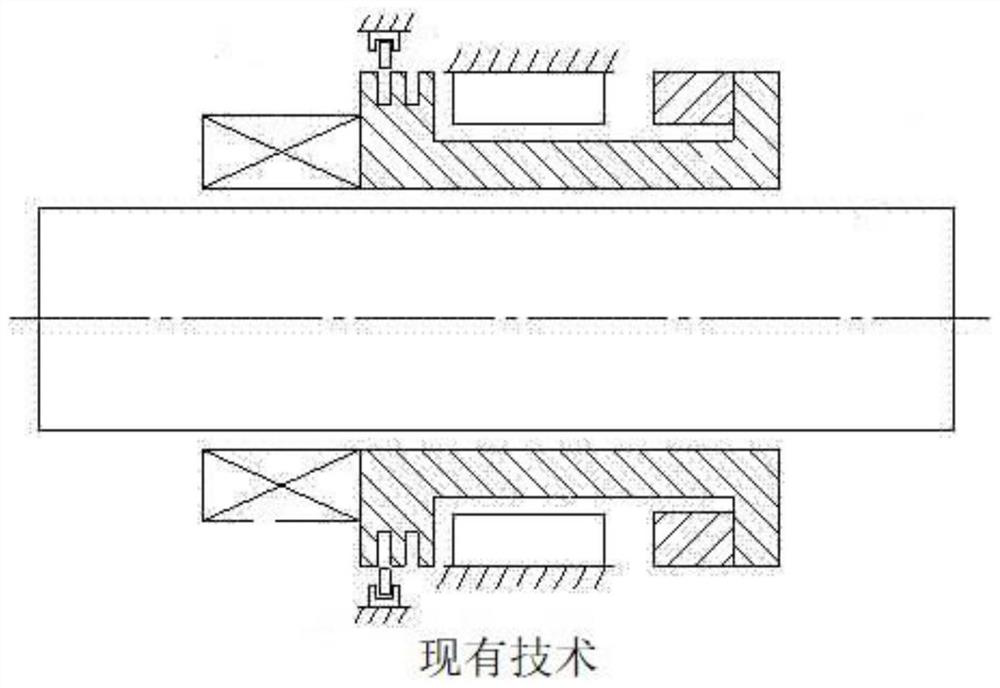

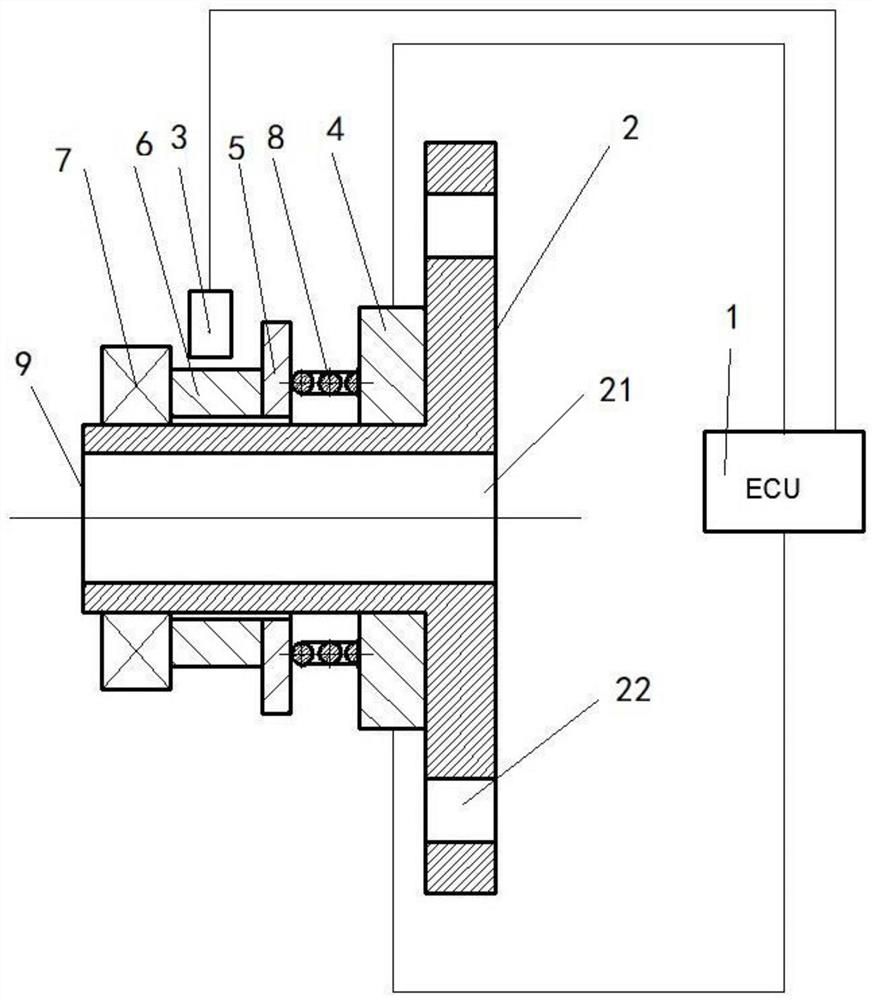

[0033] Traditional clutch actuators have been difficult to meet the current electrification requirements, such as figure 1 As shown, a clutch operating mechanism provided by the prior art can be applied to new energy vehicles with multiple power sources, and the magnetic force generated by the inductance coil is used as the execution force to push the clutch separation finger, but the operating mechanism cannot solve the problem of The problem of abnormal noise caused by parts colliding in the shaft system, and because of the lack of closed control, the movement speed and specific position of the release bearing cannot be adjusted according to the actual working conditions, and real-time control cannot be performed, which affects the driving experience. Therefore, the present embodiment provides a clutch operating system, and the clutch operating device can solve the problems mentioned above, such as figure 2 As shown, the clutch operating system includes an operating device ...

Embodiment 2

[0045] Embodiment 2 is the preferred embodiment of embodiment 1

[0046] Compared with Embodiment 1, this embodiment is preferred in that: preferably, there is one pre-compressed elastic member, and specifically, the pre-compressed elastic member is a pre-compressed coil spring, and the transmission input shaft is arranged at the The hollow part of the preloaded coil spring. The beneficial effects achieved by the clutch operating system provided in this embodiment are basically the same as those in Embodiment 1, so details will not be repeated here.

Embodiment 3

[0047] Embodiment 3 is an optional embodiment of embodiment 2

[0048] Compared with Embodiment 2, this embodiment is optional in that: as an option, there are multiple pre-compression elastic members 8, specifically, the pre-compression elastic members are pre-compression springs, and pre-compression can be set according to actual needs There are three elastic members 8, which are arranged at 120° to each other in the radial direction around the transmission input shaft. The beneficial effects achieved by the clutch operating system provided in this embodiment are basically the same as those in Embodiment 1, so details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com