Energy-saving gas stove capable of adjusting space size and sealing degree of combustion heat exchange chamber

A technology of space size and heat exchange chamber, applied in the direction of burner, combustion method, combustion type, etc., can solve the problem of temperature and heat bulk density reduction, indirect absorption, conduction and utilization of heat process, which is not conducive to high-intensity concentrated and effective heat energy conversion, etc. problem, to achieve the effect of improving the thermal energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

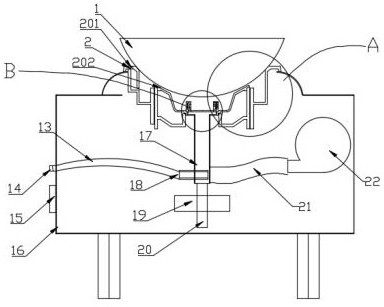

[0027] As a preferred embodiment of the present invention, a gas hose 13 and an air supply hose 21 are connected below the mixed gas delivery pipe 17, and a gas valve is provided at the end of the gas hose 13 away from the mixed gas delivery pipe 17. 14. The end of the air supply hose 21 away from the mixed gas delivery pipe 17 is provided with a blower 22 .

[0028] Specifically, a lifting mechanism 19 is provided below the mixed gas delivery pipe 17, and the lifting mechanism 19 includes a lifting mechanism support member 20, and a stove panel 16 is arranged on the side of the furnace pan frame 2, and the stove panel 16 is provided with a lifting adjustment Device 15, the lower end of the mixed gas delivery pipe 17 is closed, and is in contact with the lifting mechanism support 20 below, and the lifting mechanism support 20 is controlled to move up and down by the lifting mechanism adjustment device 15 arranged on the stove panel 16, and the mixed gas can be transported The pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com