Pressure sensor for multi-way valve accelerated life test

An accelerated life test and pressure sensor technology, applied in the field of sensors, can solve the problem of avoiding moisture in voltage materials, and achieve the effect of improving moisture resistance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

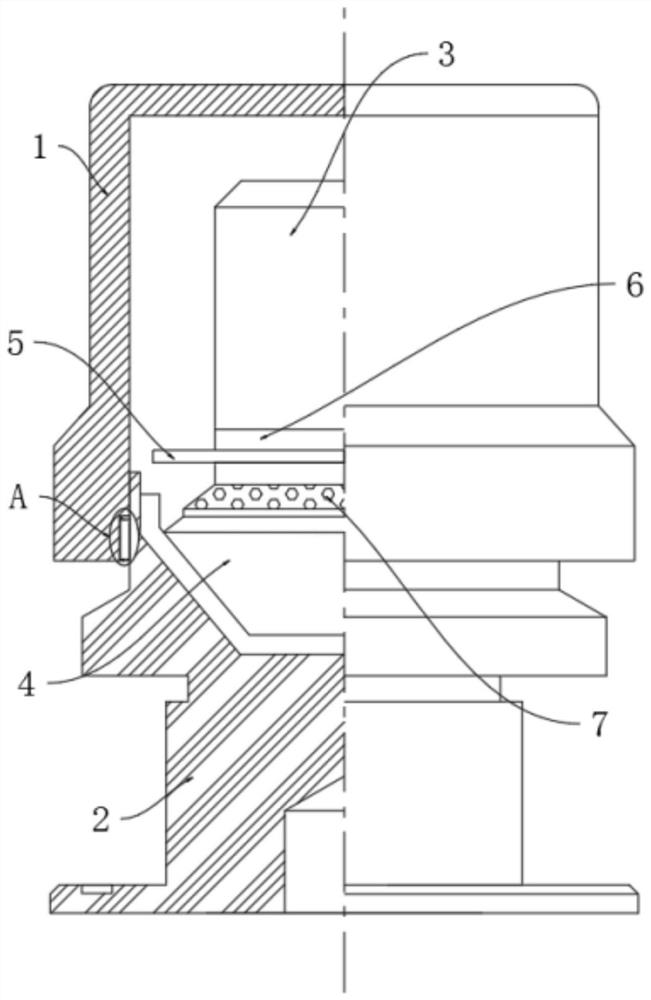

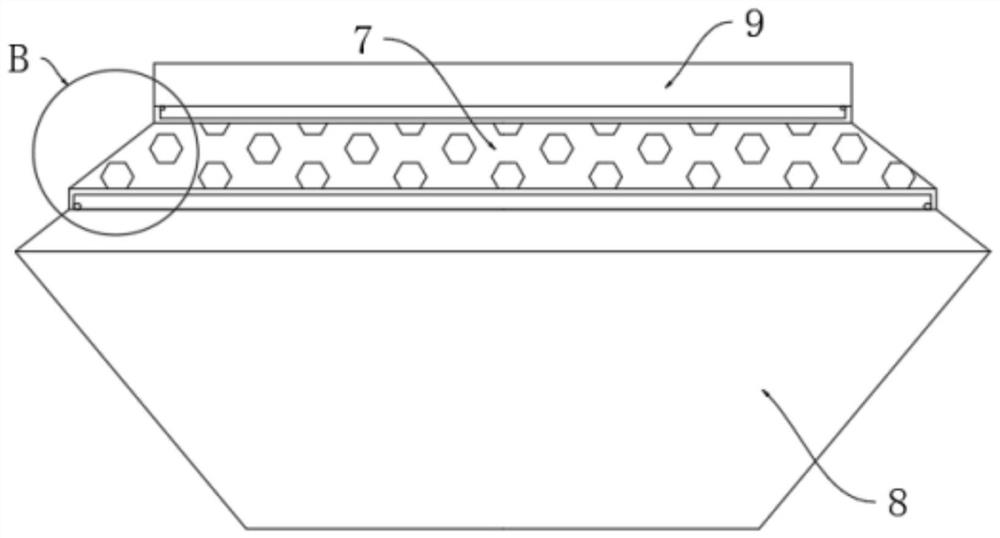

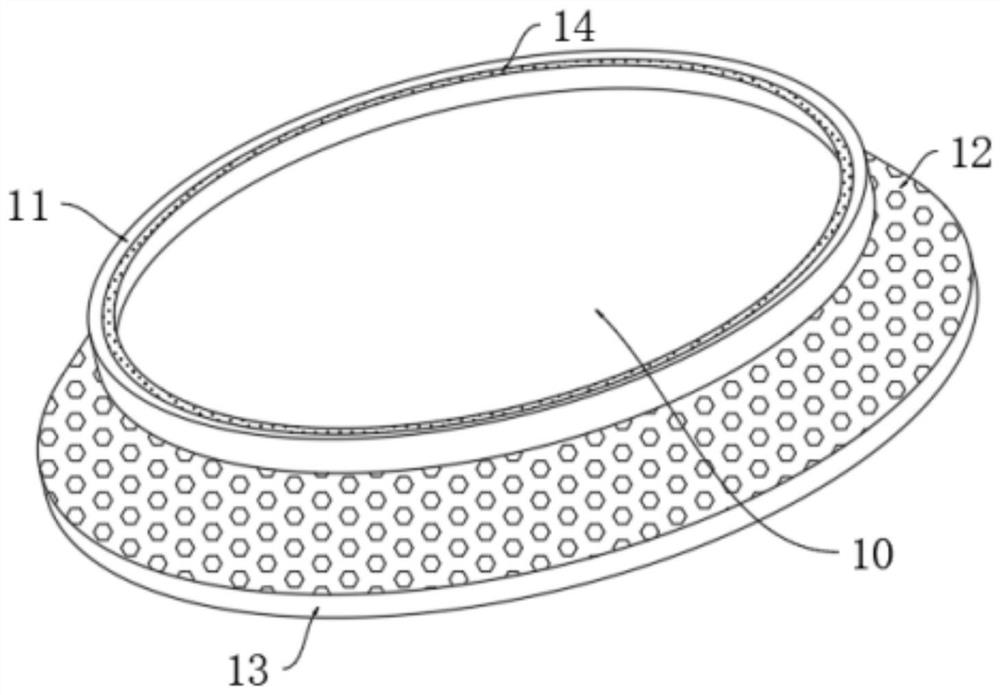

[0020]The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0021]Figure 1-5In the middle, including 1. housing; 2. base; 3. mass block; 4. support block; 5. piezoelectric ceramic wafer; 6. electrode interlayer; 7. dehumidification box; 8. lower connection block; 9. upper connection block; 10. Upper limit slot; 11. Upper connecting edge; 12. Desiccant storage box; 13. Lower connecting edge; 14. Upper limit ring; 15. Lower limit slot; 16. First bump; 17, Second bump ; 18. Lower limit ring; 19, dehumidification hole; 20, base connection seat; 21, limit edge; 22, gasket; 23, seal limit edge, etc.

[0022]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com