Method for determining gel swelling degree of cross-linked sodium hyaluronate

A technology of cross-linked hyaluronic acid and its determination method, which is applied in the field of determination of the swelling degree of cross-linked sodium hyaluronate gel, and can solve the problems of large subjective influence and inaccurate calculation results of swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

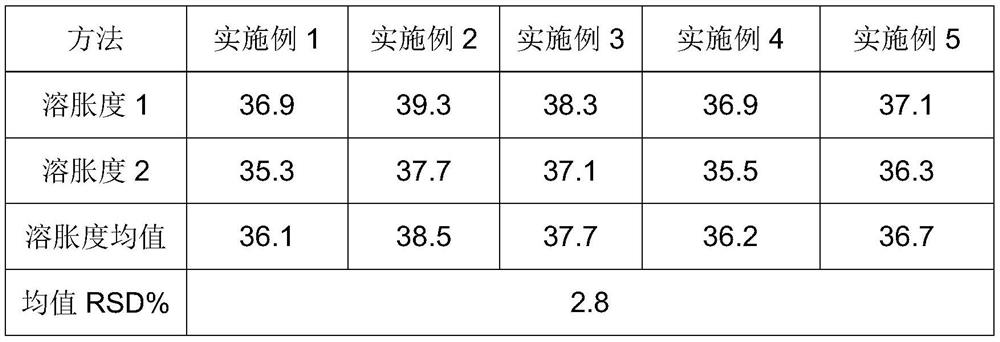

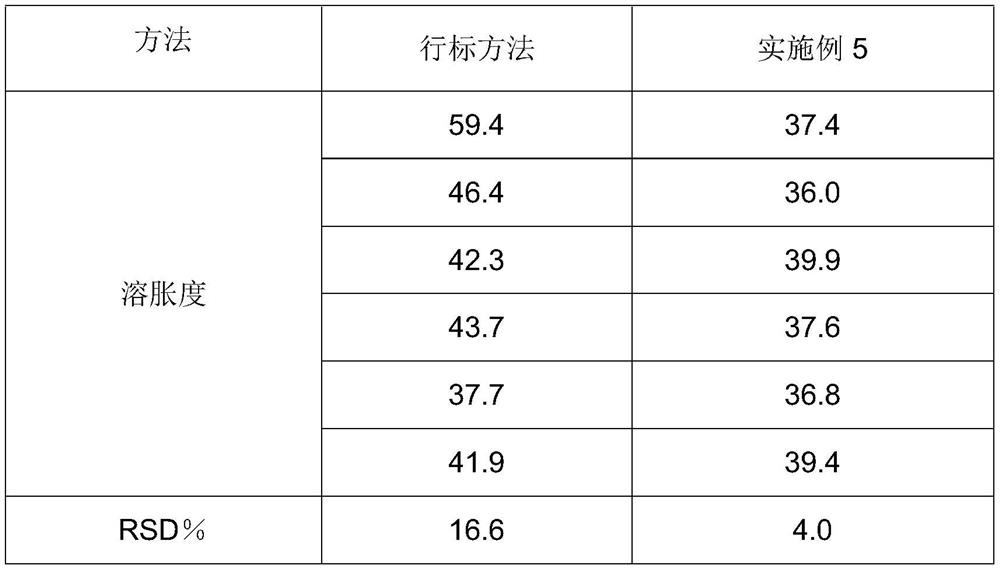

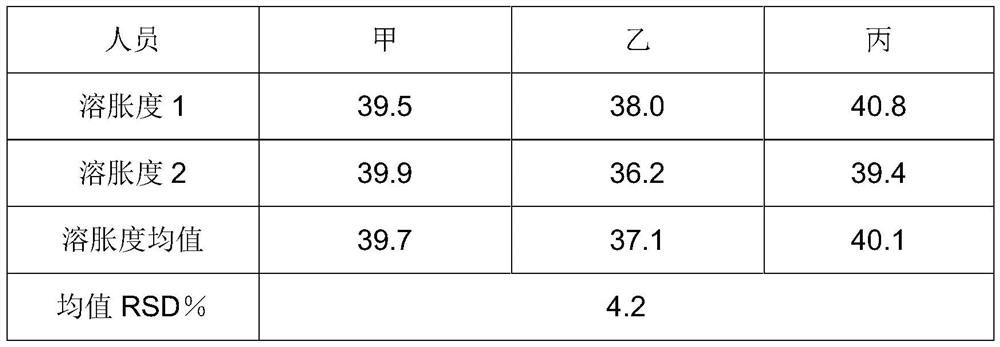

Examples

Embodiment 1

[0022] Take two 500-mesh sieves in parallel and put them in a drying oven, weigh them respectively after cooling down to constant weight at 80°C, and record them as m 0 . Weigh about 0.2 g of cross-linked sodium hyaluronate gel in parallel and place them on two 500-mesh screens, place the screens in an evaporating dish, and add 40 mL of 0.9% sodium chloride solution to completely infiltrate the sample. After swelling for 40 minutes, take out the sieve, absorb the liquid around the sieve with filter paper, weigh the total mass of each group of samples and the sieve respectively, and record it as m 1 . Then, put the sieve into a drying oven, and after cooling down to constant weight at 80°C, weigh the total mass of each group of samples and the sieve respectively, and denote it as m 2 . Calculate the degree of swelling (Q)=(m 1 -m 2 ) / (m 2 -m 0 ), and take the average value as the measurement result.

Embodiment 2

[0024] Take two 500-mesh sieves in parallel and put them in a drying oven, weigh them respectively after cooling down to constant weight at 80°C, and record it as m 0 . Weigh about 0.2 g of cross-linked sodium hyaluronate gel in parallel and place them on two 500-mesh screens, place the screens in an evaporating dish, add 20 mL of 0.9% sodium chloride solution to completely infiltrate the sample. After swelling for 40 minutes, take out the sieve, absorb the liquid around the sieve with filter paper, weigh the total mass of each group of samples and the sieve, and denote it as m 1 . Then, put the sieve into a drying oven, weigh the total mass of each group of samples and the sieve respectively at 80°C until constant weight, and denote it as m 2 . Calculate the degree of swelling (Q)=(m 1 -m 2 ) / (m 2 -m 0 ), and take the average value as the measurement result.

Embodiment 3

[0026] Take two 500-mesh sieves in parallel and put them in a drying oven, weigh them respectively after cooling down to constant weight at 80°C, and record it as m 0 . Weigh about 0.2 g of cross-linked sodium hyaluronate gel in parallel and place them on two 500-mesh screens, place the screens in an evaporating dish, add 20 mL of 0.9% sodium chloride solution to completely infiltrate the sample. After swelling for 20 minutes, take out the sieve, absorb the liquid around the sieve with filter paper, weigh the total mass of each group of samples and the sieve, and denote it as m 1 . Then, put the sieve into a drying oven, weigh the total mass of each group of samples and the sieve respectively at 80°C until constant weight, and denote it as m 2 . Calculate the degree of swelling (Q)=(m 1 -m 2 ) / (m 2 -m 0 ), and take the average value as the measurement result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com