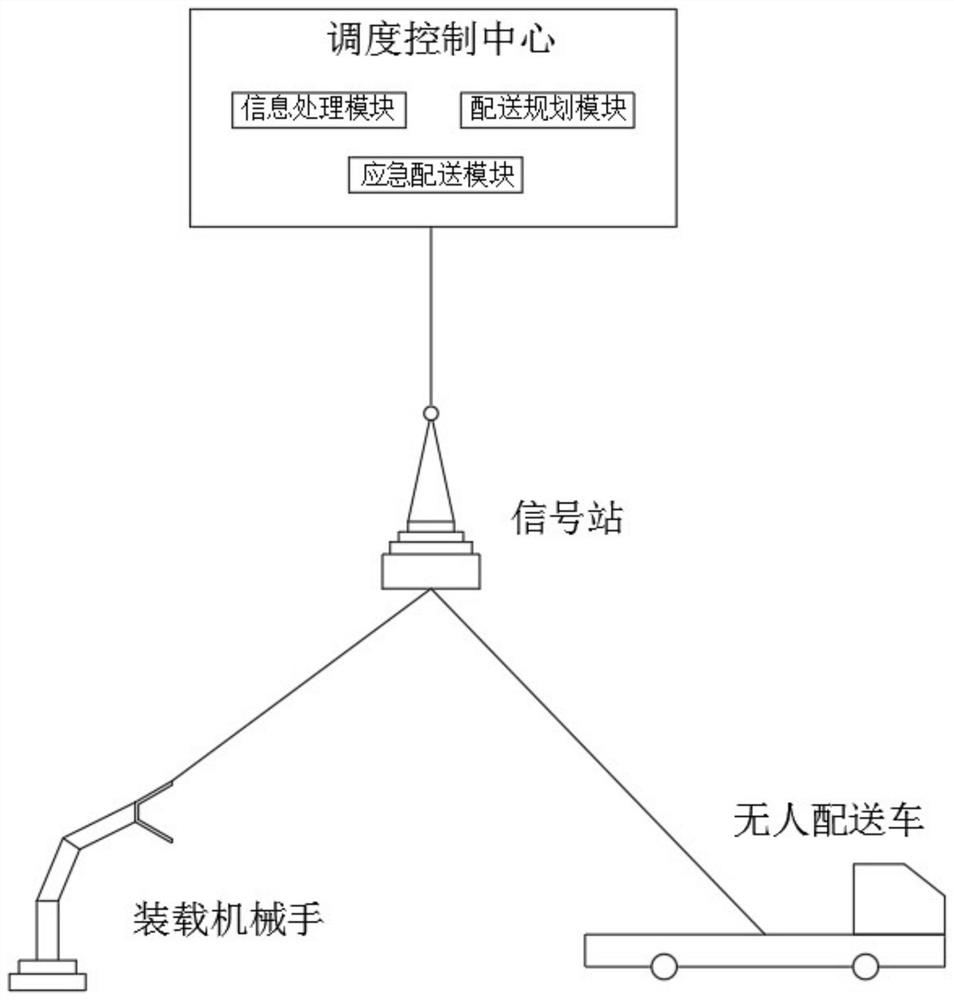

Material distribution scheduling control system and method

A scheduling control and scheduling control center technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as unfavorable workshop production, inability to meet workshop material distribution requirements, and increase material scheduling and distribution time costs. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

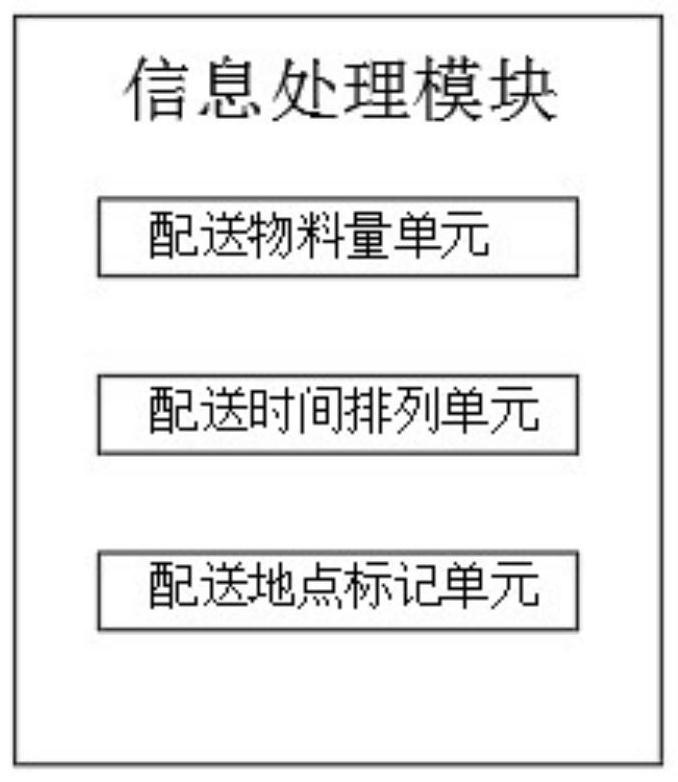

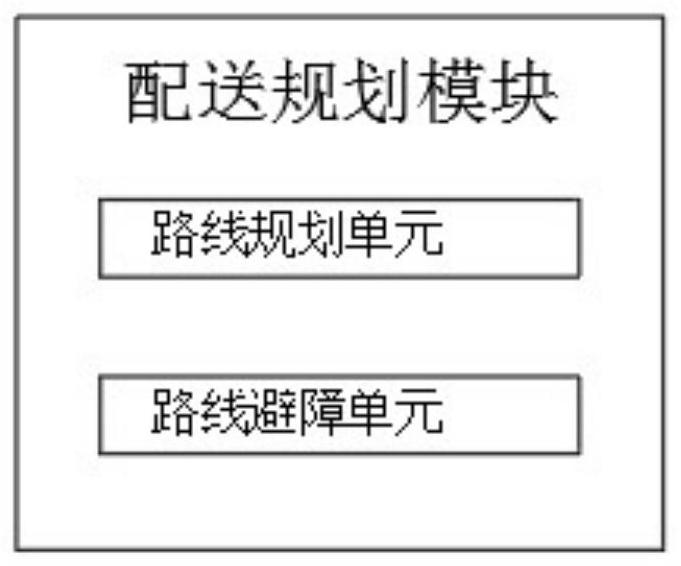

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0040] A material distribution scheduling control method, comprising the following steps:

[0041] S1: The dispatch control center receives the distribution request information of the materials required by each workshop, and uniformly forms a material distribution request form;

[0042] S2: Separate the information in the material delivery request form to generate corresponding delivery scheduling control instructions;

[0043] S3: The loading manipulator receives the scheduling control command, and loads the materials in the material warehouse onto the unmanned delivery vehicle as needed;

[0044] S4: The unmanned delivery vehicle delivers materials to each worksho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com