Container and material management system

A management system and container technology, applied in the field of office automation, can solve the problem of lack of refinement, high efficiency, practicality, safety, and easy expansion of material management system, daily average frequency of inbound and outbound receipts and receipts, large amount of receipts and receipts, and untimely acquisition of material management data, etc. problem, to achieve the effect of improving data accuracy, realizing automatic generation, and improving data real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

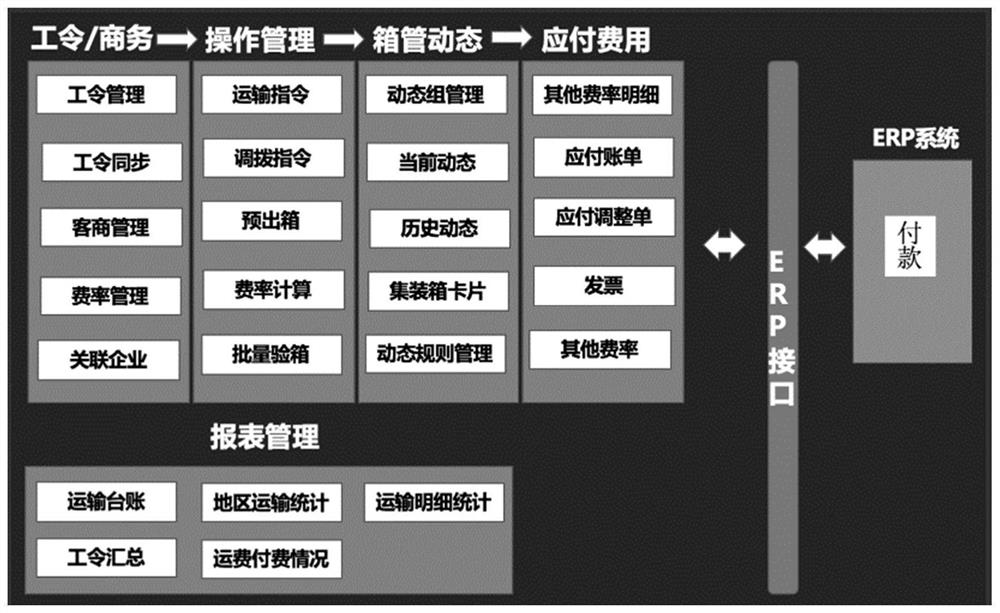

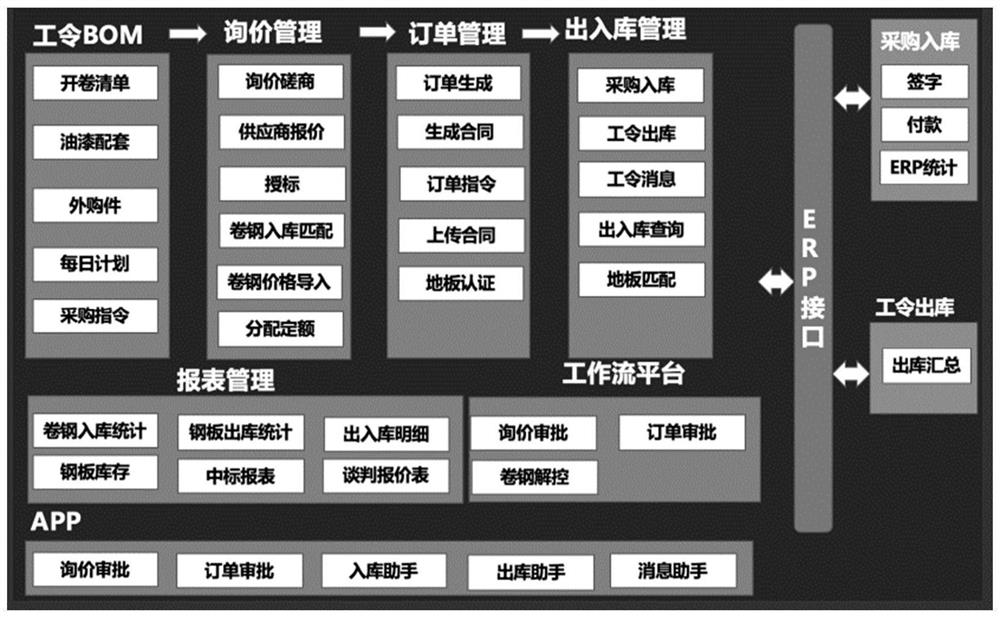

[0031] Example: such as figure 1 , 2 As shown, the embodiment of the present invention includes a container and material management system, which is based on microservice technology architecture and containerized management, and is deployed on an enterprise private cloud based on Docker container technology as a whole, and the PC-side technical framework is based on Spring+Mybatis The package of the lightweight J2EE architecture, the front-end interface layer adopts react technology, uses the ant design UI framework; the back-end adopts the micro-service architecture, uses RPC communication, Zookeeper as the registration center, uses Redis cache service, Nacos configuration center, and uses Tomcat as the The system application server is deployed on the Linux operating system. The mobile terminal infrastructure adopts the MVVM design pattern. Android uses okhttp to communicate with the network, and at the same time uses the Glide image loading framework to be rich in function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com