Cathode material and preparation method and application thereof

A cathode material and substrate technology, applied in the field of electrochemistry, can solve problems such as gaps in market demand, and achieve the effects of low Li/Ni mixing degree, strong crystal structure stability, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

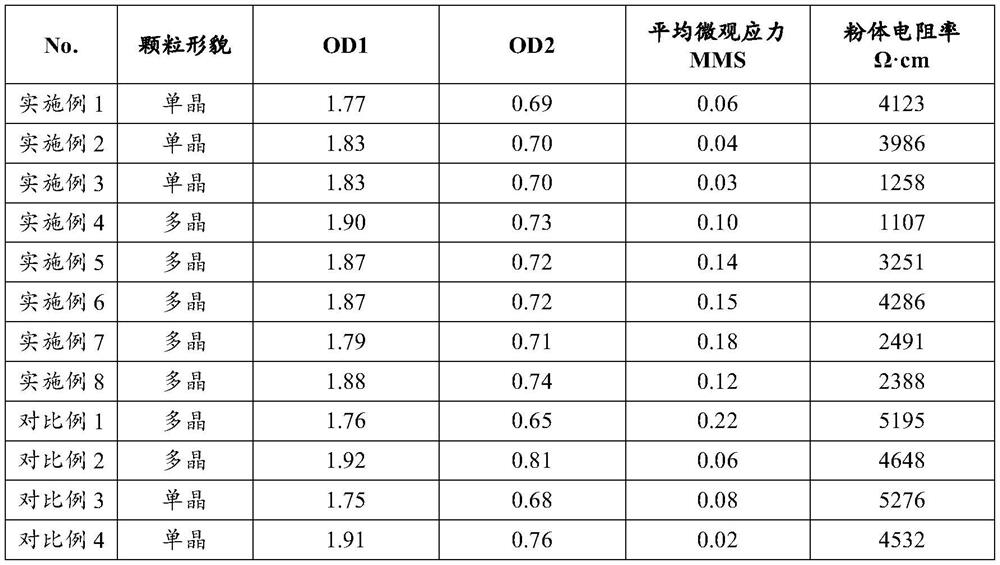

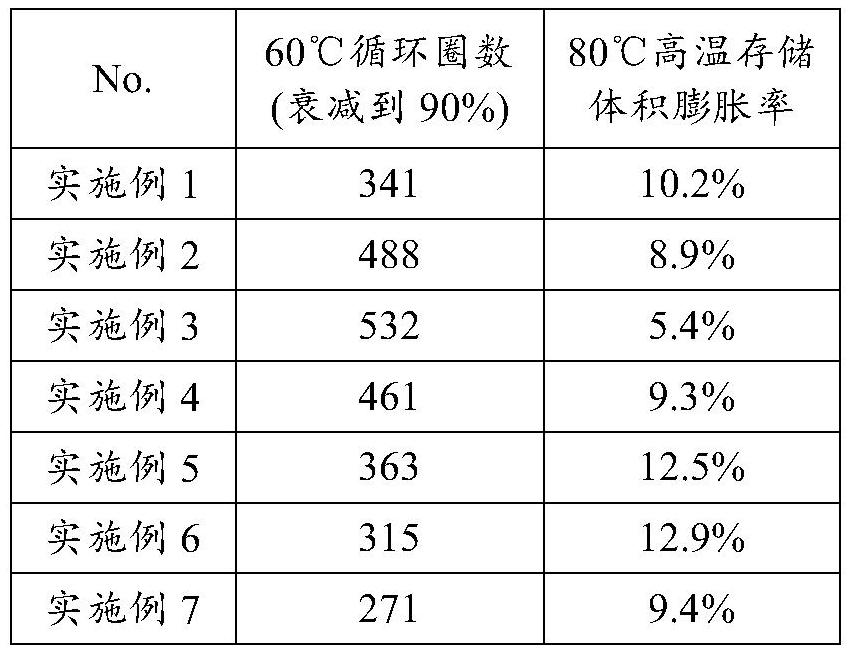

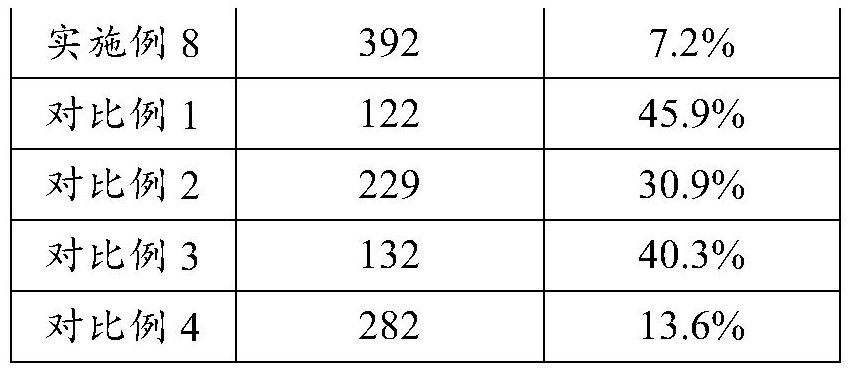

Examples

preparation example Construction

[0033] The second aspect of the present invention provides the preparation method of the positive electrode material, comprising: mixing and sintering raw materials of the substrate to provide the substrate. Those skilled in the art can control the degree of oxygen deficiency in the ternary material by adjusting processes related to oxygen combination such as precursor preparation process and powder sintering process. Specifically, the positive electrode material provided by the first aspect of the present invention is provided by adjusting the speed, temperature, and pH of the stirring process during the precursor synthesis process, and the sintering temperature, sintering time, and oxygen flow rate during the sintering process. The raw materials needed to prepare the base material should be known to those skilled in the art. For example, the raw materials of the base material may include nickel-cobalt-manganese and / or aluminum ternary material precursors, lithium sources, M ...

Embodiment 1

[0045] Preparation of cathode material:

[0046] Step 1: Prepare the substrate precursor, configure nickel sulfate, manganese sulfate, and cobalt sulfate in a molar ratio of 8:1:1 to form an aqueous solution with a concentration of 1mol / L. Under the condition of 11, stir for 6 hours, age at room temperature for 12 hours, filter and wash to prepare the precursor Ni of the transition metal oxide with a thickness of 9 μm to 11 μm 0.8 co 0.1 mn 0.1 (OH) 2 .

[0047] Step 2: the substrate precursor Ni obtained in step 1 0.8 co 0.1 mn 0.1 (OH) 2 1. Lithium hydroxide is placed in a high-speed mixer for mixing, the molar ratio of the substrate precursor to lithium hydroxide is 1.05, and then the mixture is placed in an oxygen atmosphere furnace (30% oxygen content) for sintering at 910°C for 10h, At the same time, the crushing treatment of the airflow is carried out, that is, the positive electrode material substrate with a single crystal structure is obtained;

[0048] Step ...

Embodiment 2

[0050] The difference from Example 1 lies in that 0.2wt% zirconia is added in step 2, and the sintering temperature is set to 900°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com