Liquid crystal emulsion composition for sheet mask, preparation method therefor, and sheet mask comprising same

A technology of liquid crystal emulsification and composition, which is applied in the direction of cosmetic preparations, dressing preparations, skin care preparations, etc., which can solve the problems of application restrictions and achieve the effect of excellent skin transmission ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0092] Preparation Example 1: Preparation of Liquid Crystal Emulsion Composition

[0093] The water phase ingredients of Table 1 were mixed in the main mix tank and heated at a temperature of 78°C to dissolve the ingredients. In addition, the oil phase components were heated in another oil phase tank, and the components were dissolved by heating at a temperature of 78° C. similarly. Add the dissolved oil phase ingredients to the main mix tank and mix with a homomixer for 10 minutes.

[0094]After stirring, it was cooled to 40° C., and the skin functional ingredient was added, followed by mixing for 5 minutes. Cool to 28°C and stir while mixing.

[0095] 【Table 1】

[0096]

[0097]

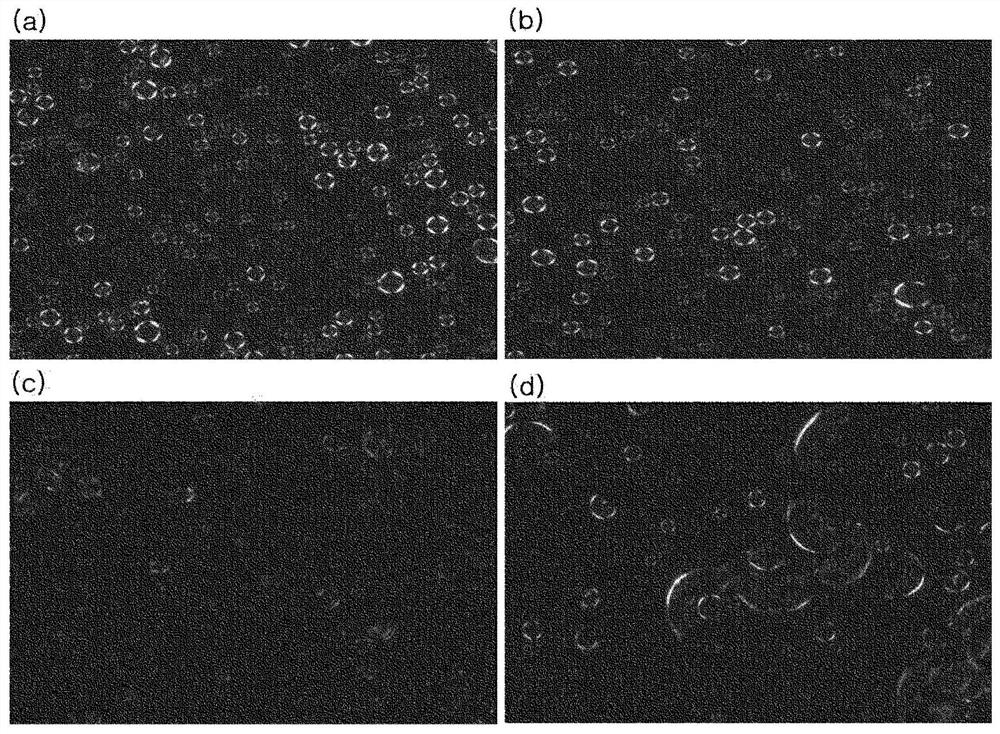

[0098] Observe the particle state of the liquid crystal emulsion prepared in described embodiment and comparative example with 400 times polarizing microscope, and show in figure 1 .

[0099] The observation results of the polarizing microscope were evaluated according to the clarity and...

preparation example 2

[0104] Preparation Example 2: Preparation of Liquid Crystal Emulsified Mask

[0105] The liquid crystal emulsion composition prepared in Preparation Example 1 was put into the mask-shaped porous network fiber structure inserted in the bag, and the liquid crystal emulsion mask was prepared by natural immersion.

[0106] Take a part of the fiber structure of the mask as a sample, and use a 400-fold polarizing microscope to observe whether the liquid crystal emulsified particles are enclosed in the porous pores of the microporous structure of the fiber structure of the mask, and the observation results are shown in figure 2 and Table 3.

[0107] 【table 3】

[0108] Example 1 Example 2 Comparative example 1 Comparative example 2 grain clarity 5 4.5 1 1 Particle uniformity 5 4.5 1.5 1.5

[0109] Depend on figure 2 As can be seen from Table 3, it can be confirmed that the liquid crystal emulsified particles are well enclosed between the fi...

experiment example 1

[0110] Experimental example 1: Performance analysis according to the type of liquid crystal emulsifier

[0111] Performance was analyzed by comparing the liquid crystal emulsifier of the present invention with an emulsifier of the prior art in combination with cetearyl alcohol and cetearyl glucoside as liquid crystal emulsifiers.

[0112] A liquid crystal emulsifying composition was prepared with the same composition as in Example 1, and the type of liquid crystal emulsifying agent was changed to cetearyl alcohol and cetearyl glucoside, and the same content as the composition of Example 1 was added in experiments The case (Comparative Example 3) and the case of adding the content to obtain the same viscosity as in Example 1 (Comparative Example 4).

[0113] 【Table 4】

[0114]

[0115]

[0116] In the above-mentioned Table 4, in the case of the liquid crystal emulsifier of Comparative Example 3, when the same content as that of the liquid crystal emulsifier of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com