Black tea beverage and production system and method thereof

A production system, technology of black tea, applied in the field of black tea beverage and its production system, can solve problems such as inability to grind solid raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

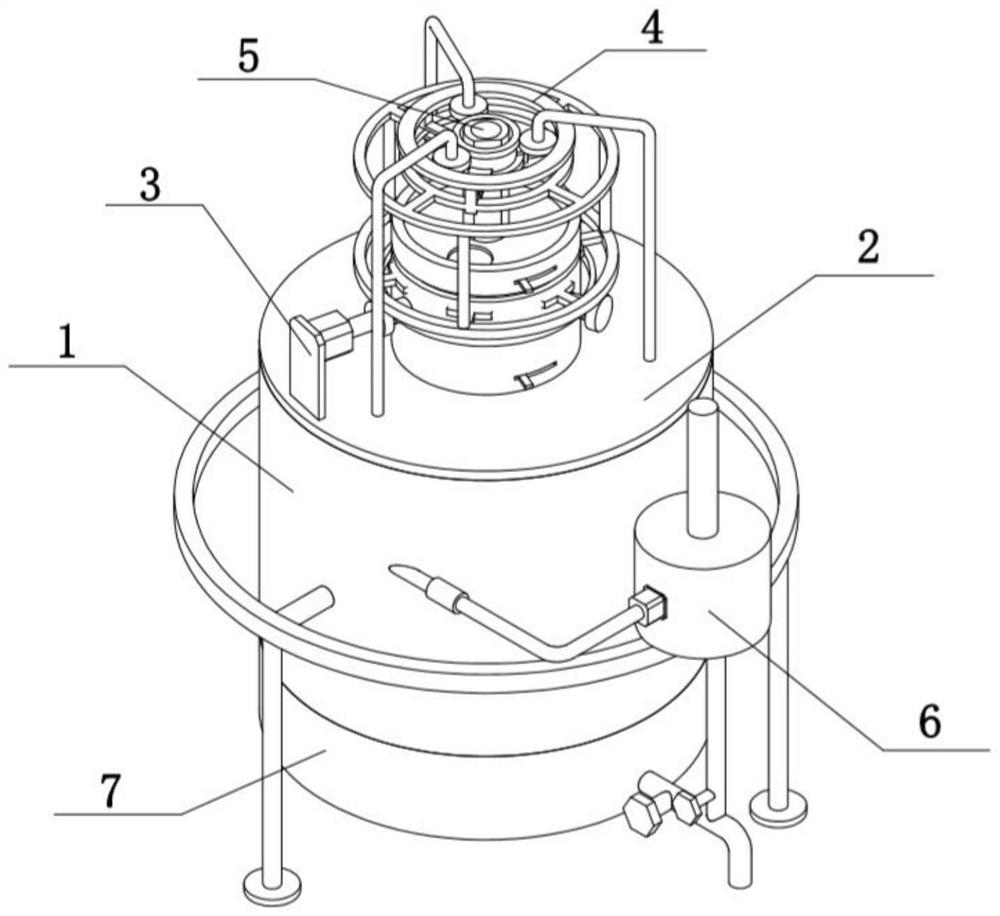

[0037] Combine below Figure 1-10 Describe this embodiment, a black tea beverage production system, including a preparation assembly 1, an upper assembly 2, a crushing assembly 3, a transmission assembly 4, a mixing assembly 5, a water supply assembly 6 and a heating assembly 7, and the upper assembly 2 is fixedly connected in the preparation On the assembly 1, the crushing assembly 3 is fixedly connected to the upper assembly 2, the transmission assembly 4 is rotatably connected to the crushing assembly 3, the transmission assembly 4 and the crushing assembly 3 are meshed for transmission, the mixing assembly 5 is connected to the preparation assembly 1, and the mixing assembly 5 and The upper assembly 2 is engaged in transmission, the upper assembly 2 and the transmission assembly 4 are engaged in transmission, the water supply assembly 6 is fixedly connected to the preparation assembly 1 , and the heating assembly 7 is fixedly connected to the lower end of the preparation as...

specific Embodiment approach 2

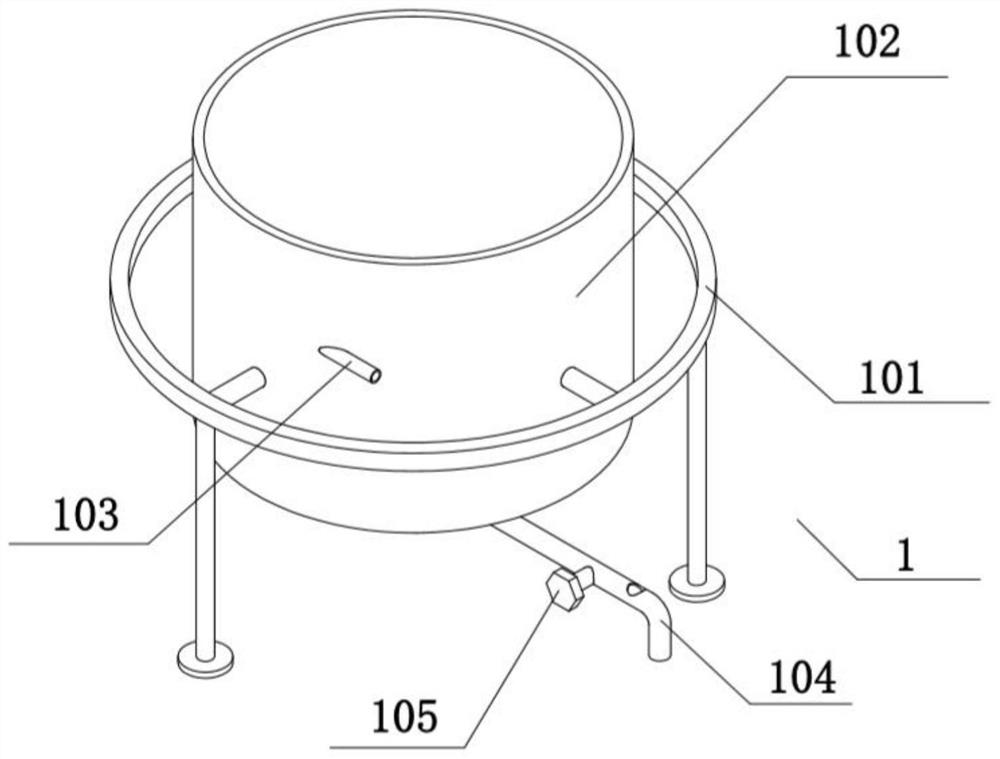

[0040] Combine below Figure 1-10 To illustrate this embodiment, the preparation assembly 1 includes a preparation support 101, a preparation barrel 102, a tangential feed pipe 103, a discharge pipe 104 and a discharge valve 105, the preparation barrel 102 is fixedly connected to the preparation support 101, and the preparation barrel 102 A tangential feed pipe 103 is arranged on the top, a discharge pipe 104 is fixedly connected to the lower end of the preparation barrel 102 , and a discharge valve 105 is arranged on the discharge pipe 104 .

specific Embodiment approach 3

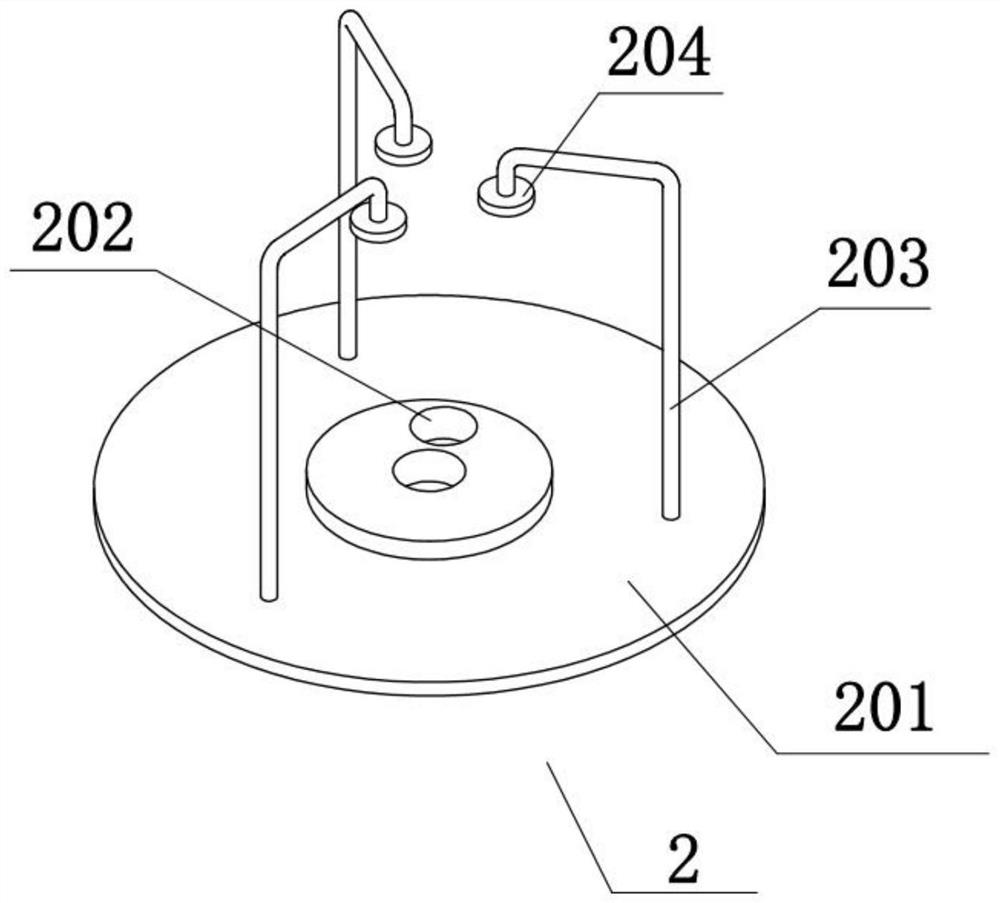

[0042] Combine below Figure 1-10 To illustrate this embodiment, the upper assembly 2 includes a stepped upper end cover 201, a solid feeding hole 202, a differential lever 203 and a differential gear 204, the stepped upper end cover 201 is provided with a solid feeding hole 202, and the stepped upper end cover 201 A plurality of differential rods 203 are evenly distributed, and a differential gear 204 is rotatably connected to each of the plurality of differential rods 203 , and the stepped upper end cover 201 is detachably connected to the preparation barrel 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com