Punch, die and stretching process for stretching battery jar body

A technology of battery cans and punches, which is applied in the field of can body processing, which can solve the problems of easy tearing of the end of the can body, the decrease of the energy density of the battery pack, and the increase of the weight of the battery pack, etc., so as to save arrangement space and improve space utilization The effect of efficiency and material reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Example: A battery can body stretching process

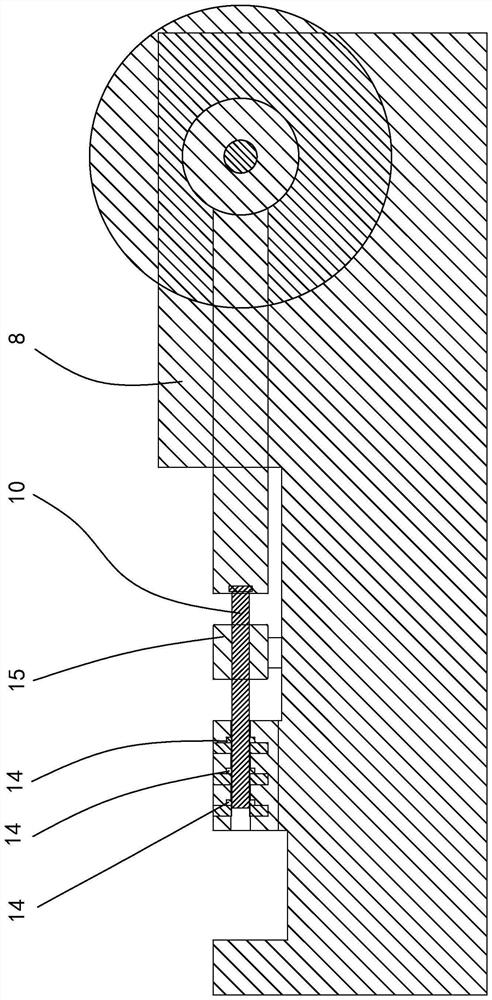

[0047] Please refer to the attached figure 1 To attach Figure 9 , a stretching process for a battery can body, used to stretch out a variable-wall-thickness can body suitable for end seaming, that is, the axial middle of the can body is a thin-walled section 16, and the two ends are thick-walled sections 17. The process includes the following stretching steps:

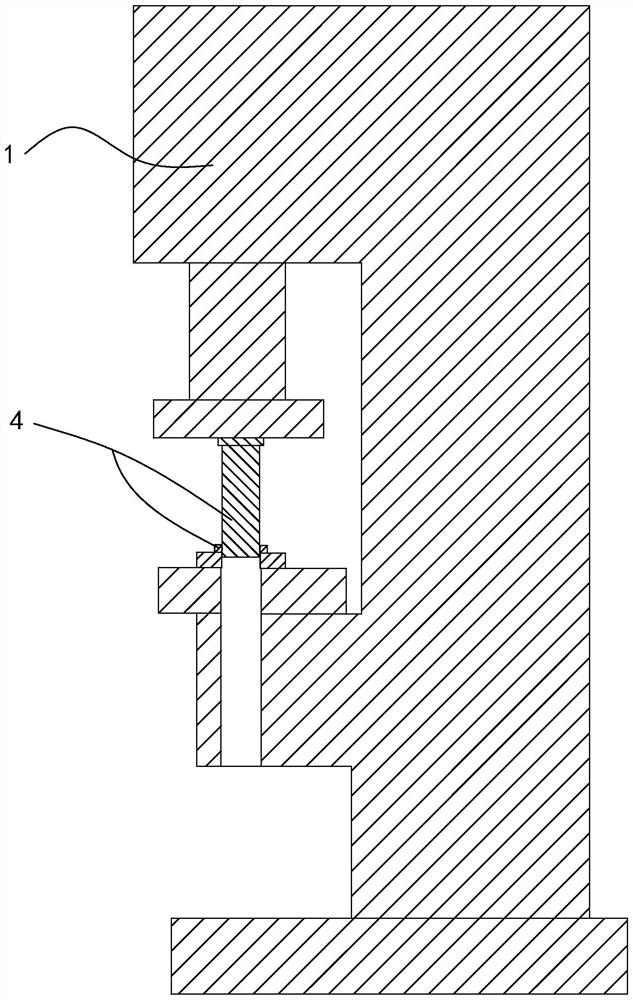

[0048] The first step: cup punching (this step belongs to forming stretching), such as figure 1 , Image 6 with Figure 7 As shown, the sheet material 2 is punched and formed by using the first punch 1 through the first die 4 to obtain a cup-shaped punching cup part 3 .

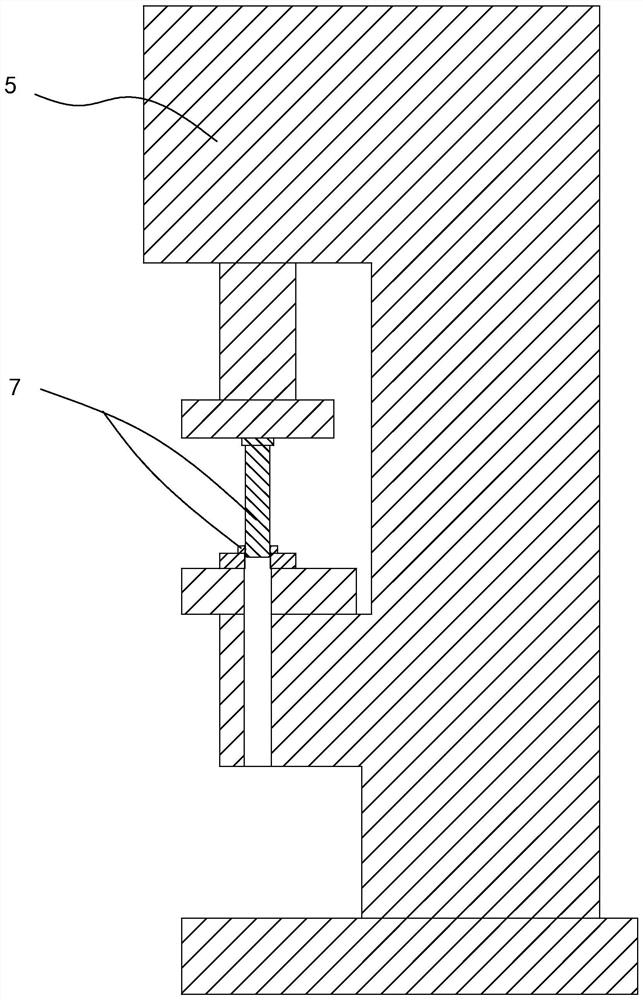

[0049] The second step: re-drawing (this step belongs to forming stretching), such as figure 2 , Figure 7 with Figure 8 As shown, the cup punching part 3 is stamped and formed by the second punch 5 through the second die 7 to obtain a cup-shaped re-drawing part 6, the inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com