Rare earth metal siphoning device and method for rare earth electrolytic cell

A technology of rare earth metals and electrolytic cells, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of easy failure of equipment, high labor intensity of operators, and surface oxidation of rare earth metals, so as to prevent oxidation, increase labor procedures, Effect of Reducing Secondary Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

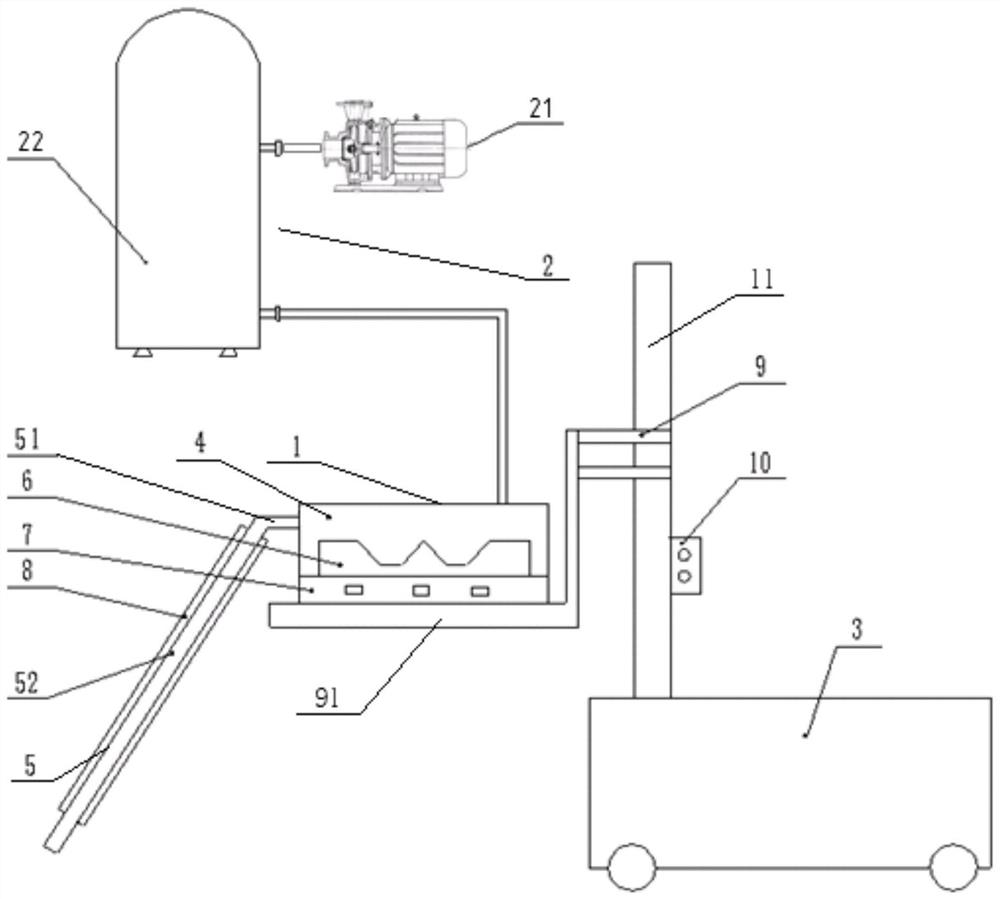

[0031] The embodiment of the present invention provides a device for siphoning rare earth metal in a rare earth electrolytic cell, which is used in conjunction with any existing rare earth electrolytic cell. The overall inventive concept is as follows:

[0032] The device includes a siphon casting bag and vacuum equipment for providing a vacuum environment to the siphon casting bag. The siphon casting bag includes a bag body, a siphon tube, a weighing device and a casting mold. One end of the siphon tube communicates with the bag body, and the other end of the siphon tube is used for extending The rare earth metal is siphoned into the rare earth electrolytic cell, the weighing equipment and the casting mold are both arranged in the package body, and the casting mold is arranged on the weighing equipment. Compared with the prior art, the present invention sets the casting mold inside the siphon casting ladle, which has both the siphon function and the ingot casting function, avo...

Embodiment 2

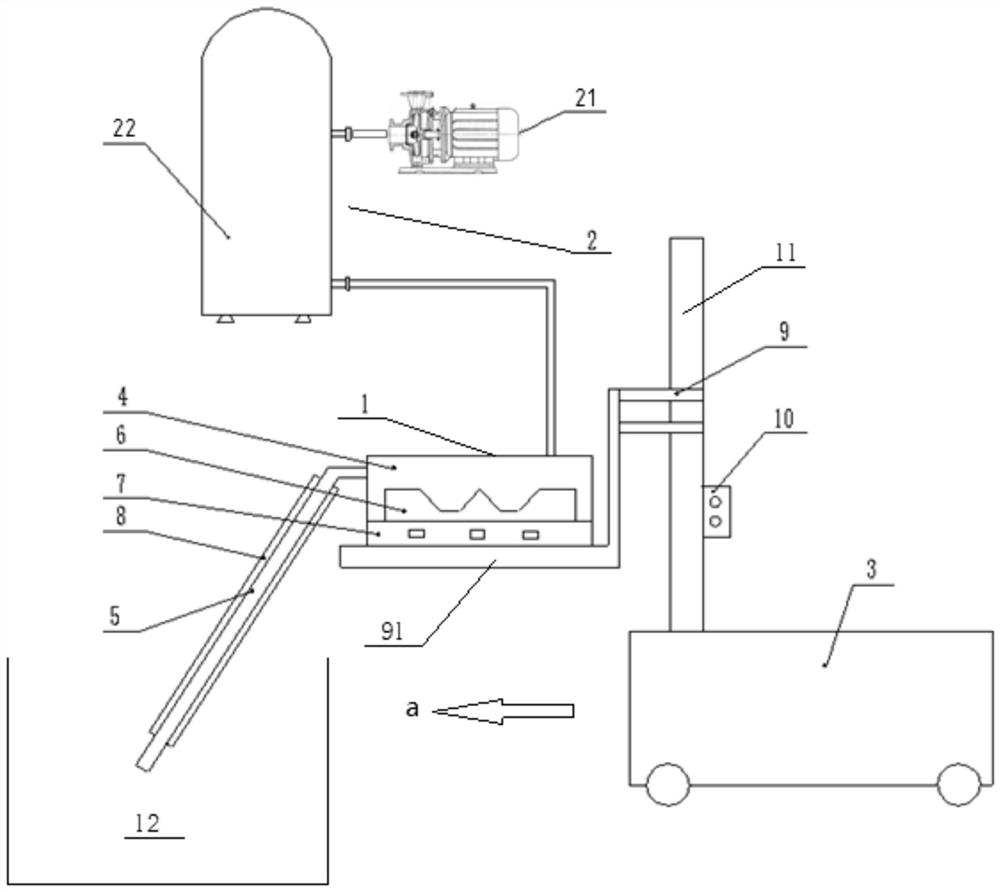

[0042] This embodiment provides a method for siphoning rare earth metals, which is implemented based on the device for siphoning rare earth metals in a rare earth electrolytic cell in the above-mentioned embodiment 1, and specifically includes the following steps:

[0043] (1) The siphon tube 5 is preheated by the preheating device 8, and the temperature of the siphon tube 5 is controlled to be 650°C to 900°C, such as 650°C, 680°C, 715°C, 770°C, 825°C, 850°C, 860°C, 865°C °C, 870 °C, 877 °C, 882 °C, 885 °C, 900 °C, etc., the temperature of the siphon tube is preferably 50 °C to 200 °C lower than the melting point of the rare earth metal; the vacuum device 2 provides a vacuum environment to the siphon casting ladle 1 to control the siphon casting ladle 1. The vacuum inside is 0.1Pa~100Pa, such as 0.1Pa, 0.2Pa, 0.35Pa, 0.5Pa, 0.65Pa, 0.7Pa, 0.77Pa, 0.85Pa, 1Pa, 10Pa, 25Pa, 42Pa, 60Pa, 80Pa, 95Pa, etc. , preferably 0.1Pa~1Pa; extend the siphon tube 5 into the rare earth metal liq...

Embodiment 3

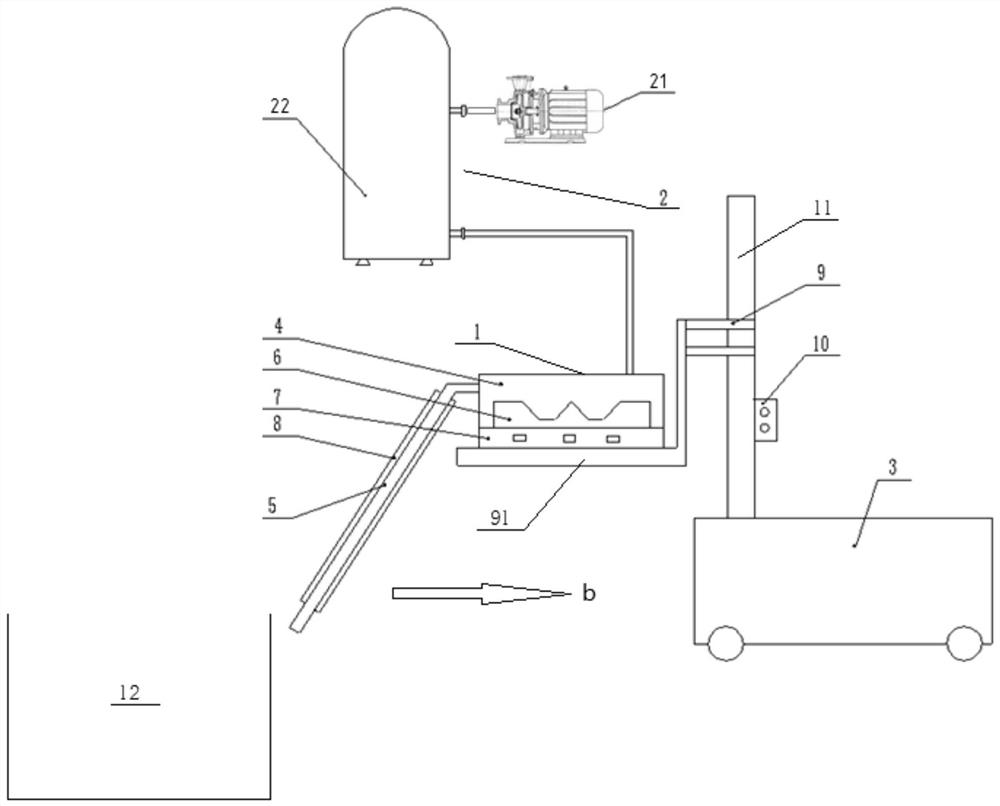

[0046] This embodiment provides a method for siphoning rare earth metals, which is implemented based on the device for siphoning rare earth metals in a rare earth electrolytic cell in the above-mentioned embodiment 1. The rare earth metal is specifically a praseodymium-neodymium alloy with a melting point of 992°C and a temperature of the melt in the furnace chamber of the electrolytic cell 1050°C. The siphon rare earth metal method specifically includes the following steps:

[0047] (1) Preheat the siphon tube 5 by the preheating device 8, and control the temperature of the siphon tube 5 to be 800°C to 850°C; provide a vacuum environment to the siphon casting ladle 1 through the vacuum equipment 2, and control the vacuum degree inside the siphon casting ladle 1 to be 0.1Pa~1Pa; extend the siphon tube 5 into the rare earth metal liquid below the electrolyte liquid level in the rare earth electrolytic cell 12, and start to siphon the rare earth metal, and the rare earth metal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com