Non-conductive magnetic yoke based on induction heating furnace and method thereof

An induction heating furnace, a non-conductive technology, applied in the direction of electric furnace heating, lighting and heating equipment, furnaces, etc., can solve the problems of high power loss of the yoke, complex structure of the yoke, large heat generation of the yoke, etc., to reduce power loss , Reduce production cost, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

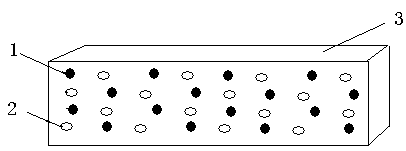

[0044] Such as figure 1 As shown, a non-conductive magnetic yoke for an induction heating furnace, the non-conductive magnetic yoke 3 is a required geometry made by uniformly mixing the soft magnetic powdery substance 1 with Portland cement or aluminate cement and adding water;

[0045] Soft magnetic powder materials include silicon steel sheet powder, ferrite powder, permalloy powder;

[0046] Non-conductive magnetic yoke formula composition and proportion:

[0047] Silicon steel sheet powder, 80%--90%; Portland cement, 10%--20%;

[0048] Specific preparation method:

[0049] a. Prepare silicon steel sheet powder, adopt pulverizer to pulverize silicon steel sheet to prepare silicon steel sheet powder, reach flour-like particle 70-90 order;

[0050] b. For the mixed material, 80%--90% silicon steel sheet powder is used, which is evenly mixed with 10%--20% portland cement; for example, 80% silicon steel sheet powder is evenly mixed with 20% portland cement; Or use 90% silic...

Embodiment 2

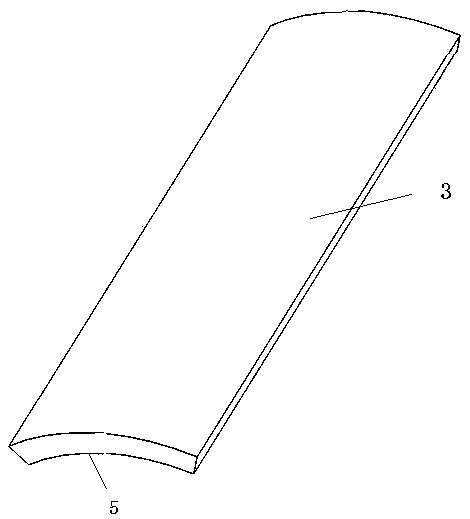

[0055] Such as figure 2 As shown, a non-conductive magnetic yoke for an induction heating furnace, the soft magnetic powder material used is ferrite powder, and the required geometry is made by uniformly mixing ferrite powder with Portland cement or aluminate cement with water;

[0056] Non-conductive magnetic yoke formula composition and proportion:

[0057] Ferrite powder: 85%--95%; aluminate cement: 5%--15%;

[0058] Specific preparation method

[0059] a. Prepare ferrite powder, adopt pulverizer to pulverize ferrite to prepare ferrite powder, and reach 70-90 mesh of flour-like particles;

[0060] b. Mixed materials, use 85%-95% ferrite powder, and mix evenly with 5%-15% aluminate cement; for example, use 85% ferrite powder and 15% aluminate cement Mix evenly; or use 95% ferrite powder and 5% aluminate cement to mix evenly;

[0061] c. adding water to the mixed powdery substance to make a soft magnetic pasty substance;

[0062] d. Then put the soft magnetic paste-like...

Embodiment 3

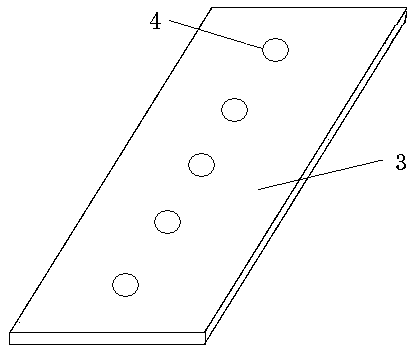

[0065] Such as image 3 As shown, a non-conductive magnetic yoke for an induction heating furnace, the soft magnetic powdery material used is permalloy powder, and the required geometry is made by uniformly mixing permalloy powder with Portland cement or aluminate cement with water;

[0066] Non-conductive magnetic yoke formula composition and proportion:

[0067] Permalloy powder, 65%--75%; aluminate cement, 25%--35%;

[0068] Specific preparation method:

[0069] a. prepare permalloy powder, adopt pulverizer to pulverize permalloy to prepare permalloy powder, reach flour-like particle 70-90 order;

[0070] b. For the mixed material, use 65%--75% permalloy powder and mix it evenly with 25%--35% aluminate cement; for example, use 65% permalloy powder and 35% aluminate cement Mix evenly, or use 75% permalloy powder and 25% aluminate cement to mix evenly;

[0071] c. adding water to the mixed powdery substance to make a soft magnetic pasty substance;

[0072] d. Then put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com