Pseudo-single crystal pipe and preparation method thereof

A quasi-single crystal and tube technology, applied in the field of materials, to achieve the effect of suppressing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Example material: 5N high-purity aluminum (99.999% by weight)

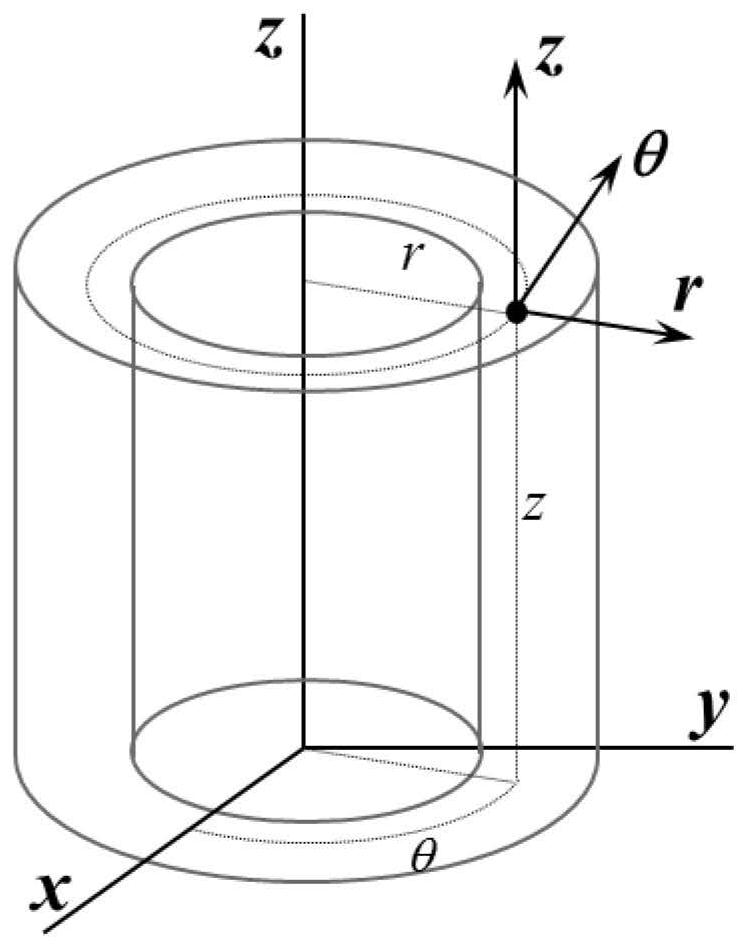

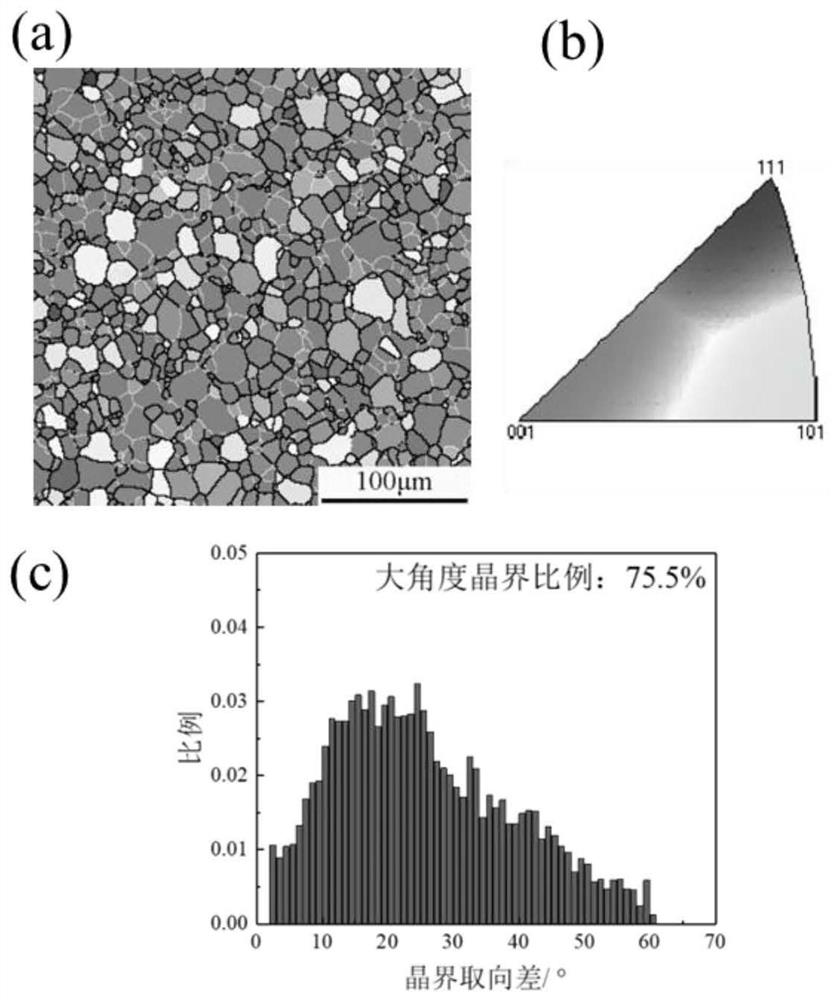

[0051] A quasi-single crystal tube, the crystallographic texture of the quasi-single crystal tube is continuously rotationally symmetric around the axis of the tube, and the proportion of large-angle grain boundaries with a grain boundary orientation difference greater than 15° in the tube is ≤10%, and the quasi-single crystal A certain orientation of the crystal in the crystal tube material The preferred orientation is parallel to the circumferential direction of the tube; the preferred orientation of a certain crystal plane {hkl} of the crystal in the quasi-single crystal tube is parallel to the tangent plane of the tube wall or the normal direction of the crystal plane is parallel to the radial direction of the tube.

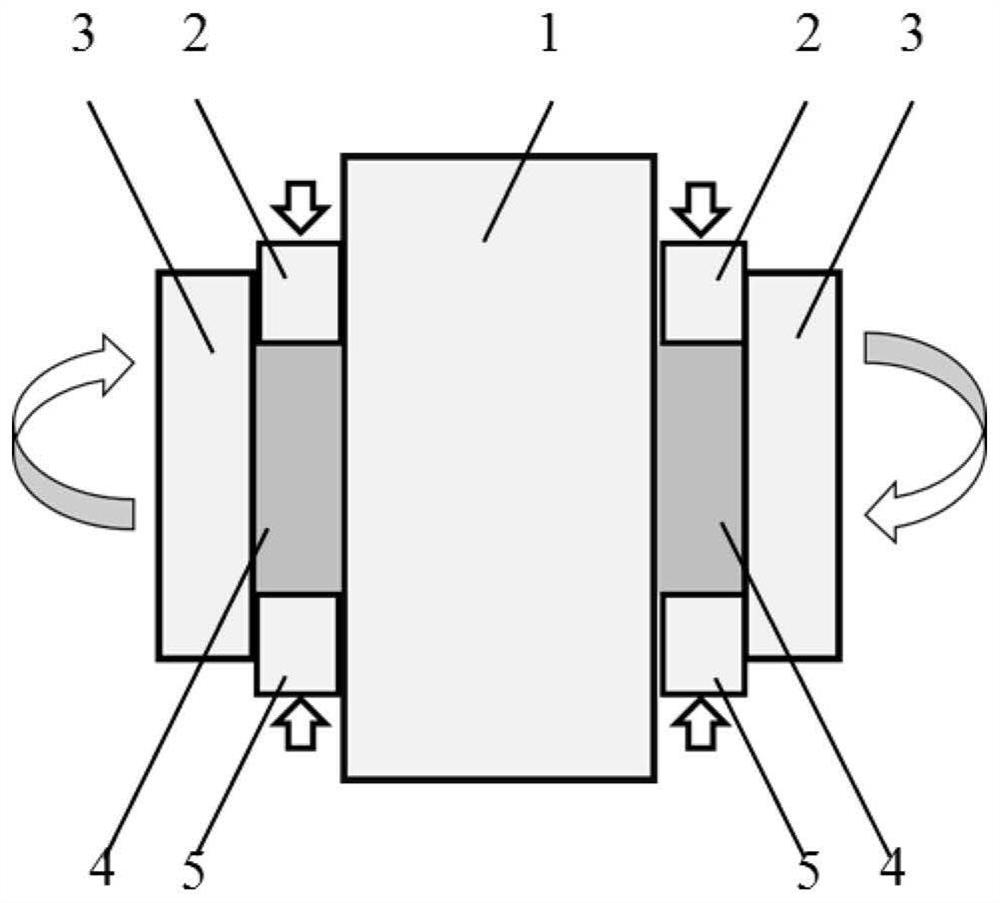

[0052] A method for preparing a quasi-single crystal tube, comprising the following steps:

[0053] (1) Prepare 5N high-purity aluminum multi-transistor material samples according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com