Method for preparing microcapsules by layer-by-layer assembly technology using oil-in-water microemulsion as template

A layer-by-layer assembly and micro-emulsion technology, applied in the micro-nano field, can solve the problems of difficult separation and removal, strong corrosiveness, etc., and achieve the effects of mild conditions, stable capsule wall and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

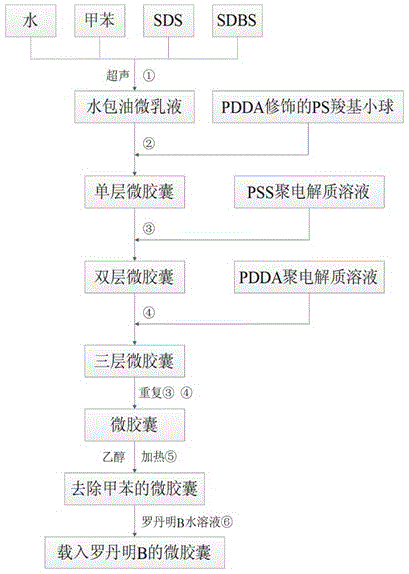

[0016] Specific implementation mode one: as figure 1 As shown, the present embodiment prepares microcapsules according to the following steps:

[0017] (1) Preparation of oil-in-water microemulsion: firstly clean the reaction vessel thoroughly, add 100μl~15ml distilled water, 0.1~30mg sodium dodecylbenzenesulfonate (SDBS), 0.01~3.0mg dodecane Sodium sulfonate (SDS) and 1μl~5ml toluene, first vortex for 1~5min to make it into a simple emulsion, then ultrasonic for 5~40min, as figure 1 Shown in step ①.

[0018] (2) Preparation of PS carboxyl beads / PDDA (polydiallyldimethylammonium chloride) suspension: add 1-30 μl of PS (polystyrene ) carboxyl pellets, shaken, and after 10min~5h, a suspension of PDDA-modified PS carboxyl pellets was obtained.

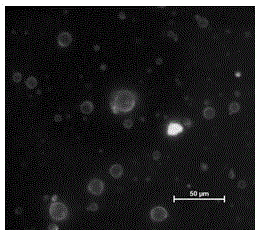

[0019] (3) Preparation of microcapsules using the oil-in-water microemulsion as a template: Centrifuge the prepared oil-in-water microemulsion (3000~8000rpm, 1~8min), remove the supernatant liquid with a syringe, such as figure 1 As s...

specific Embodiment approach 2

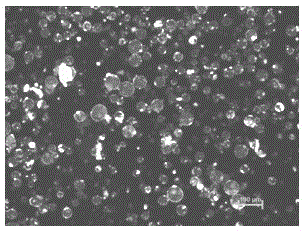

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in the process of making oil-in-water, not only toluene can be used to carry out experiments as the oil phase, but also vegetable oils such as soybean oil and olive oil and liquid paraffin (such as image 3 shown), chloroform (when chloroform is used instead of toluene, the centrifuged product is in the lower layer, and the supernatant to be removed is the supernatant, other steps are the same as toluene) and other components that can be used as raw materials for experiments.

specific Embodiment approach 3

[0023] Specific embodiment three: this embodiment is different from specific embodiments one and two in that CTAB (cetyltrimethylammonium bromide) can also be used to replace the above-mentioned surfactant as an oil-in-water surfactant, which The dosage is 0.1~30mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com