Lubrication system for power end of high-power electrically-driven fracturing sled

A lubricating system and high-power technology, applied in the direction of engine lubrication, lubricating parts, lubricating oil control valves, etc., can solve the problem of fracturing skid dimensions, overall layout effects, unfavorable disassembly and maintenance of the whole machine, safe transportation, weight It can improve the lubrication effect and service life, facilitate transportation and disassembly, and improve the heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

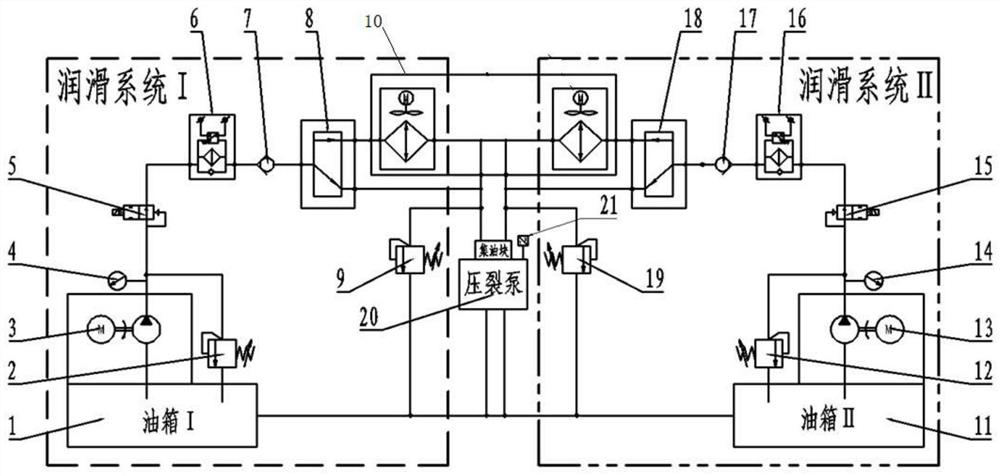

[0017] The present invention is a high-power electric drive fracturing skid power end lubrication system, such as figure 1 As shown, including lubrication system Ⅰ and lubrication system Ⅱ, the two systems operate synchronously or independently;

[0018] Lubrication system I includes suction assembly I3, the oil inlet of suction assembly I3 is connected to oil tank I1 through pipelines, and the oil outlet of suction assembly I3 is connected to solenoid valve I5, filter I6, check valve I7, temperature Control valve I8, the first outlet of the temperature control valve I8 is connected to the fracturing pump 20 through the radiator I10, the second outlet of the temperature control valve I8 is connected to the fracturing pump 20, and the oil inlet of the fracturing pump 20 is connected to the oil tank through the safety valve I9 I1 connected;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com