Household garbage pyrolysis energy storage controllable pyrolysis bin

A technology for domestic waste and energy storage, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problem that the pyrolysis treatment technology is difficult to achieve large-scale, restricts waste pyrolysis treatment devices, and is difficult to achieve high temperature environments, etc. problems, to achieve the effect of eliminating dioxin hazards, reducing costs, maintaining continuity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

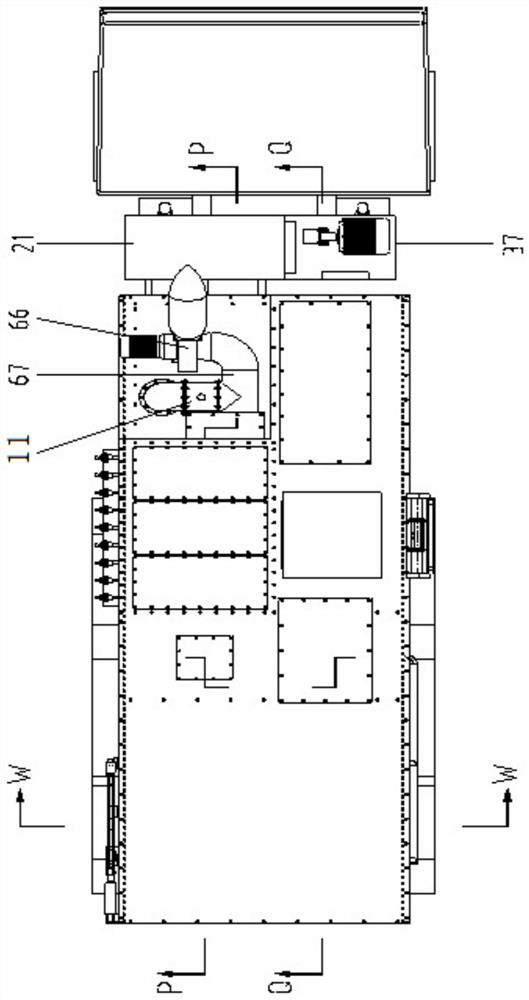

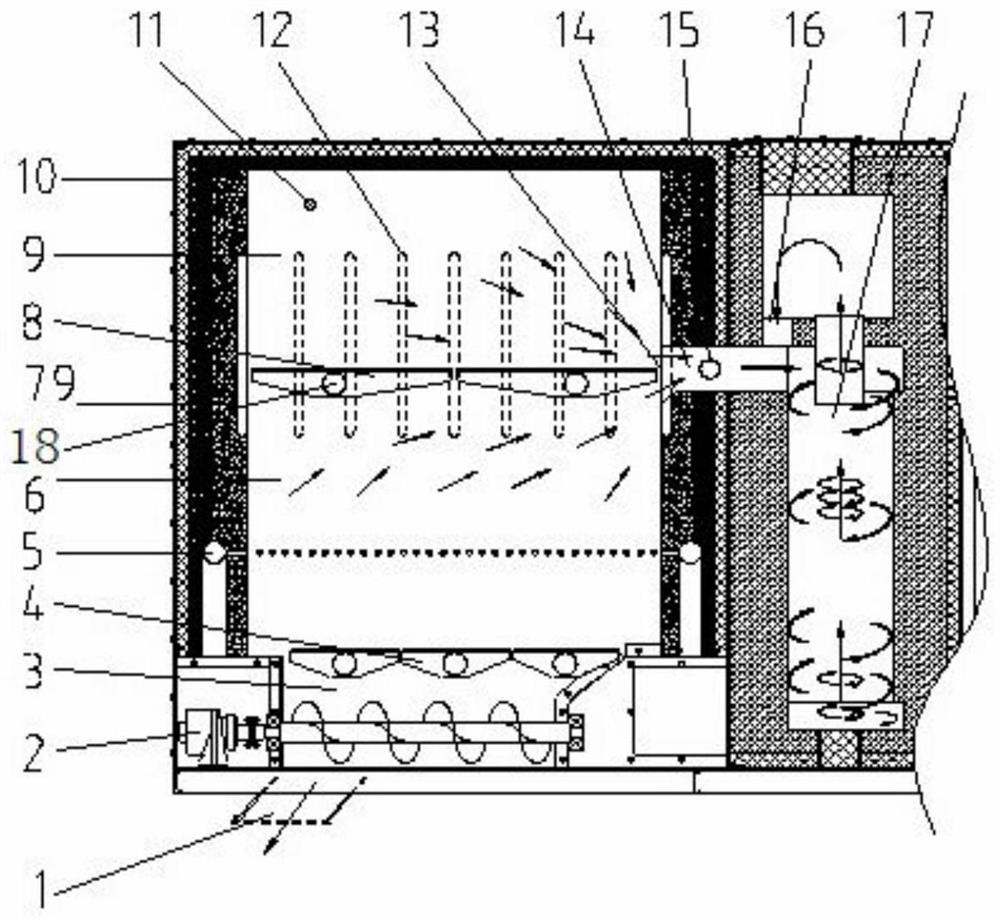

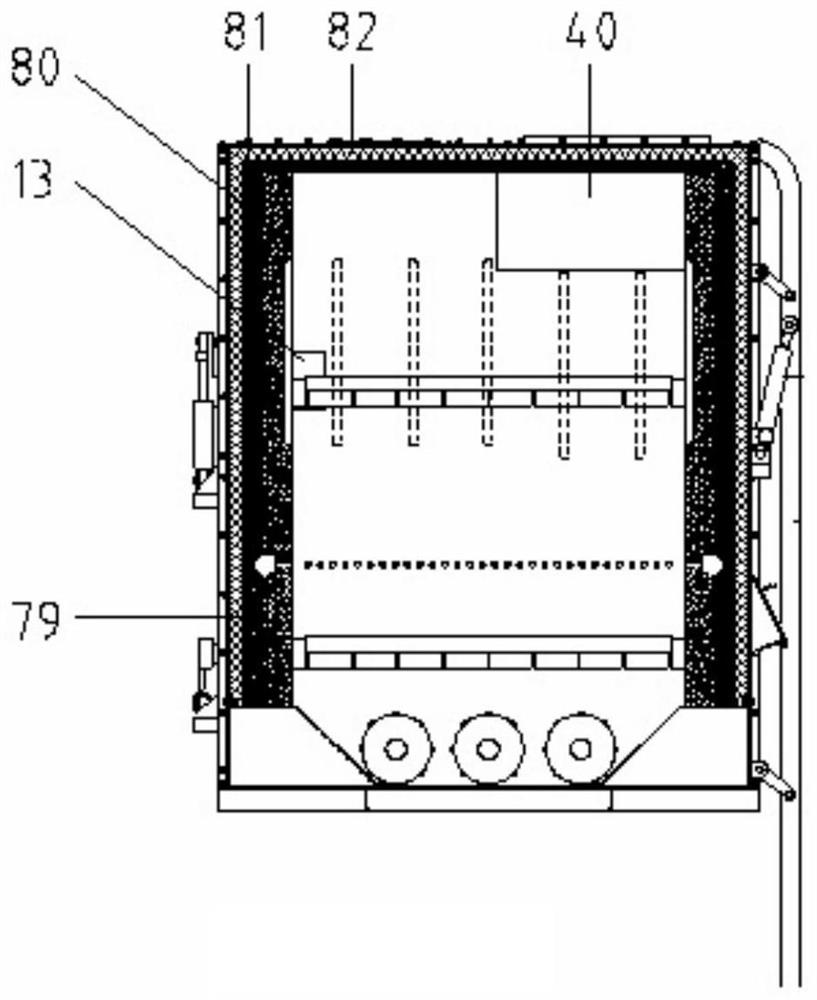

[0022] The domestic garbage pyrolysis energy storage controllable pyrolysis bin of the present invention is as follows: Figure 1-3 As shown, include pyrolysis bin 9 and incineration bin 6, energy storage wall 79, heat pipe row 12 and high temperature resistant energy storage turnover plate 8, and supporting hydraulic overturning mechanism. The first combustion chamber energy storage controllable pyrolysis chamber 9 and incineration chamber 6 are the main chambers for the pyrolysis treatment of domestic waste in the mobile domestic waste pyrolysis treatment station, wherein the energy storage controllable pyrolysis chamber 9 is located in the first combustion chamber The upper layer, the incineration bin 6 is located in the middle layer of the first combustion chamber, and below the energy storage controllable pyrolysis bin 9.

[0023] The energy storage controllable pyrolysis bin 9 is a hexahedral square structure, the surrounding and top floors are energy storage walls 79, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com