Optimal control method for improving automatic ignition success rate of boiler fuel oil

A technology of automatic ignition and optimal control, which is applied in the direction of combustion ignition, combustion method, ignition by electric spark, etc., can solve the problems of advancing the ignition time of the igniter, prolonging the ignition time, etc., and achieve the effect of avoiding frequent flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

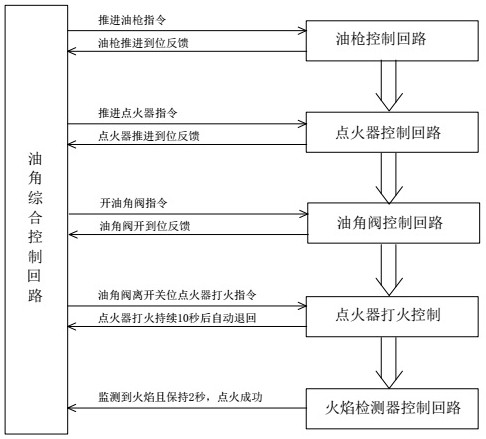

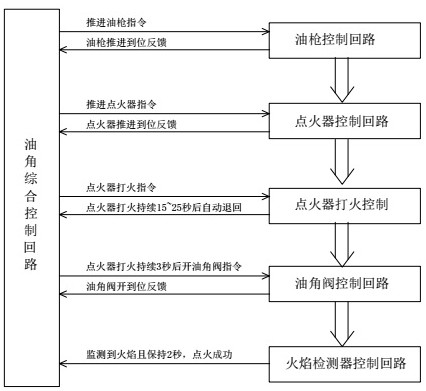

[0019] see figure 2 , an optimized control method for improving the success rate of automatic ignition of boiler fuel oil, including an integrated oil angle control loop and an oil gun control loop, and sub-control loops such as an igniter control loop, an oil angle valve control loop, and a flame detector control loop.

[0020] The oil angle integrated control circuit sends out the oil angle start command. After the oil gun control circuit receives the instruction, the oil gun starts to advance; after the oil gun is advanced in place, it sends a signal to the igniter control circuit, and the igniter starts to advance; after the igniter is in place, The igniter starts to ignite, and after a delay of 3 seconds, a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com