High-sensitivity temperature detection device based on cantilever beam

A detection device and a cantilever beam technology are applied in the field of temperature detection, which can solve the problems of low detection sensitivity and achieve the effects of high temperature detection sensitivity and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

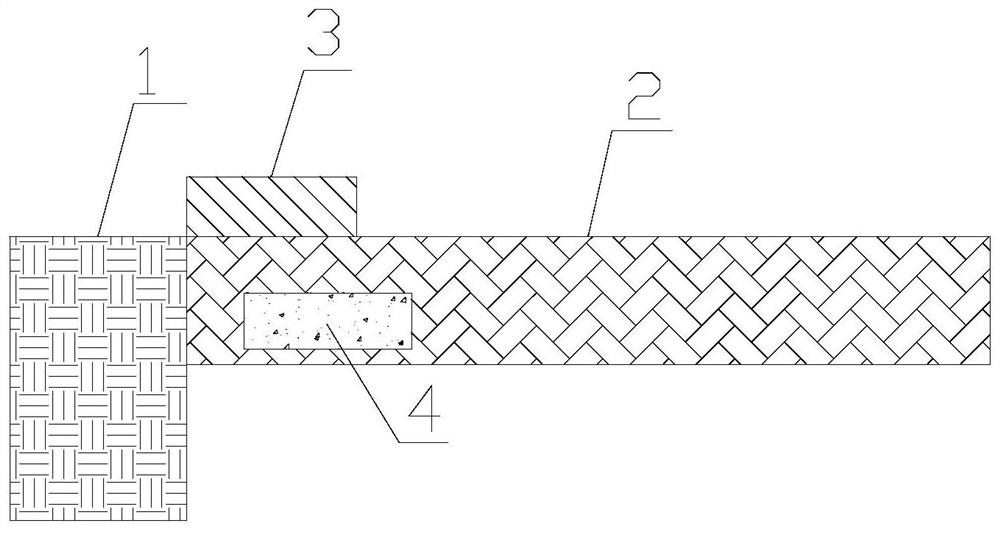

[0021] The invention provides a high-sensitivity temperature detection device based on a cantilever beam. like figure 1 As shown, the high-sensitivity temperature detection device based on a cantilever beam includes a vibration source 1 , a cantilever beam 2 , a piezoelectric material block 3 , and a thermal expansion material part 5 . The cantilever beam 2 is fixed on the vibration source 1 . The vibration source 1 drives the cantilever beam 2 to vibrate. The material of the cantilever beam 2 is aluminum alloy, silicon, semiconductor material, diamond. The piezoelectric material block 3 is arranged on the top surface of the cantilever beam 2 near the fixed end, and the piezoelectric material block 3 is connected with an external circuit for detecting the vibration frequency of the cantilever beam 2 . The piezoelectric material block 3 is made of piezoelectric ceramics or polyvinylidene fluoride. The thermally expandable material portion 4 is provided inside the cantilever...

Embodiment 2

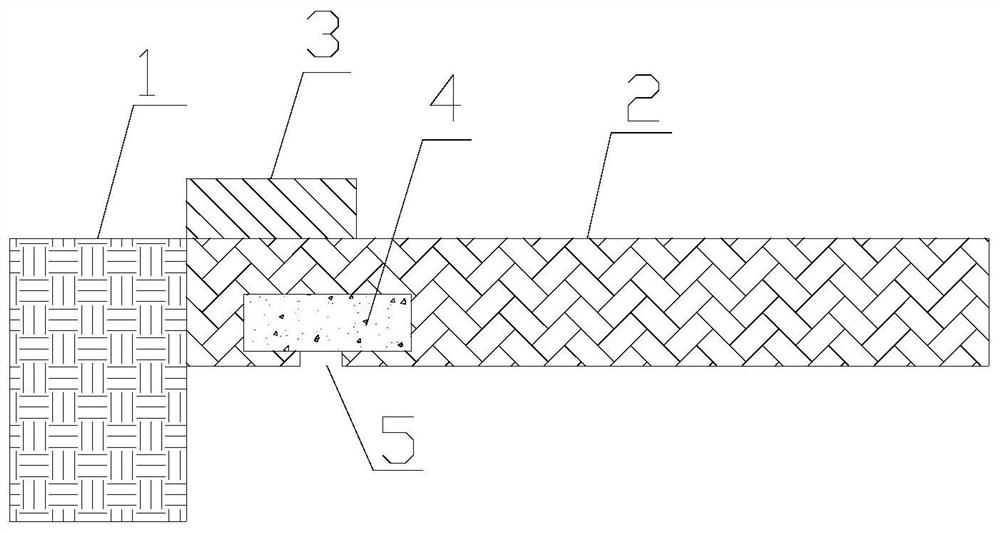

[0024] On the basis of Embodiment 1, the heat-expandable material part 4 is disposed in a position near the fixed end of the cantilever beam 2 . Under the action of the vibration source 1, when the cantilever beam 2 vibrates, a large degree of bending occurs near the fixed end of the cantilever beam 2. When the heat-expandable material part 4 is arranged in the position near the fixed end of the cantilever beam 2, the effect of the expansion of the heat-expandable material part 4 on the change of the internal stress of the cantilever beam 2 is more obvious, thereby changing the resonant frequency of the cantilever beam 2 more, thereby realizing a more stable High sensitivity magnetic field detection.

Embodiment 3

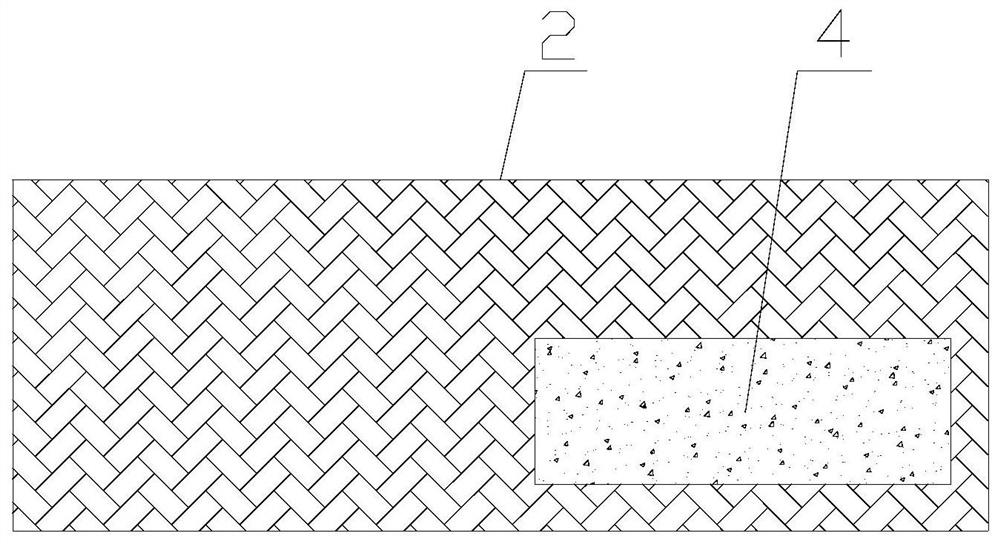

[0026] On the basis of Embodiment 2, the section of the cantilever beam 2 is rectangular. The section of the thermally expandable material part 4 is rectangular. The cross-section of the heat-expandable material part 4 is asymmetrically arranged within the cross-section of the cantilever beam 2 . In this way, the expansion of the thermal expansion material part 4 not only changes the stress in the cantilever beam 2, but also changes the stress of the cantilever beam 2 in different directions in the section of the cantilever beam 2, thus causing the cantilever beam 2 to twist. The resonant frequency of the cantilever beam 2 can be changed more precisely, so as to realize higher sensitivity magnetic field detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com