Dumpling machine forming module

A dumpling machine and dumpling technology, applied in baking, dough processing, food science and other directions, can solve the problems of high thickness requirements of dumpling skins, cracks in dumpling skins, poor dumpling shape, etc., so as to reduce the probability of broken skins and reduce processing. Steps, shape stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

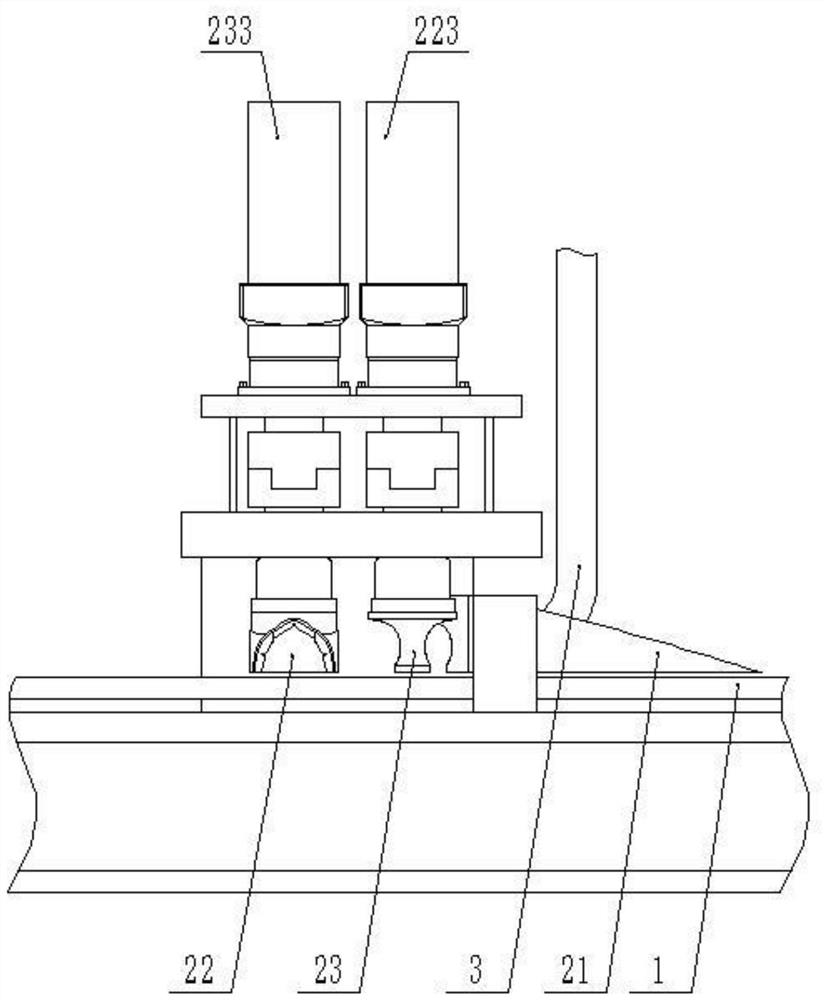

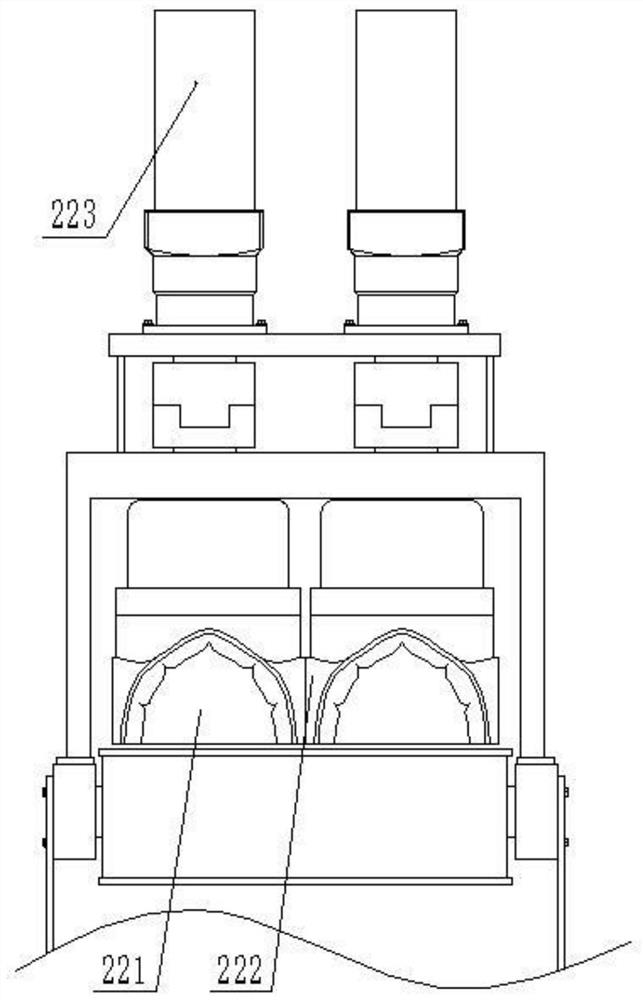

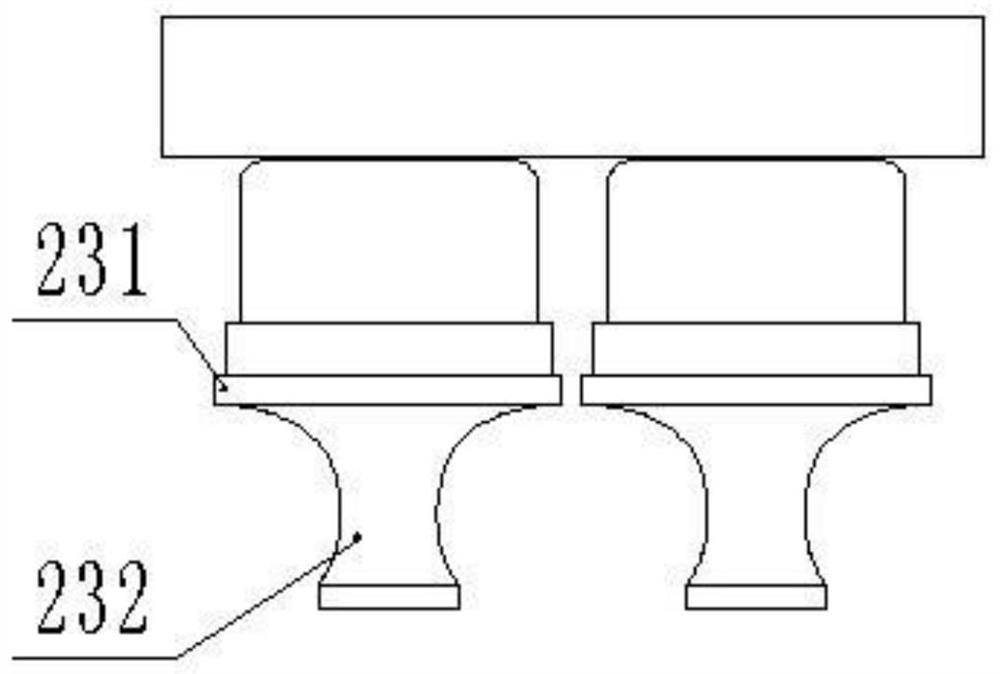

[0039] Such as Figure 1 to Figure 7 As shown: the dumpling machine forming module of the present invention includes: a conveyor belt 1 and a dumpling pressing mechanism, and a dumpling pressing mechanism is fixed above the conveyor belt 1, and the dumpling pressing mechanism includes: a skin rolling block 21 and a pressing mechanism Closing mold 22; described curling piece 21 has two, and two curling pieces 21 are symmetrically fixed on the top of conveyer belt 1, two pressing molds 22 are arranged on the conveyor belt 1 behind two curling pieces 21, so The pressing mold 22 forms a tendency to rotate around its center line, and the rotation directions of the two pressing molds 22 are opposite;

[0040] The peeling blade surface 211 and the peeling groove 212 are arranged on the peeling block 21; the peeling blade surface 211 is a spiral surface, the front end of the peeling blade surface 211 is a horizontal edge, and the peeling blade surface 211 The rear end is a vertical e...

Embodiment 2

[0058] Such as Figure 1 to Figure 7 As shown: the dumpling machine forming module of the present invention includes: a conveyor belt 1 and a dumpling pressing mechanism, and a dumpling pressing mechanism is fixed above the conveyor belt 1, and the dumpling pressing mechanism includes: a skin rolling block 21 and a pressing mechanism Closing mold 22; described curling piece 21 has two, and two curling pieces 21 are symmetrically fixed on the top of conveyer belt 1, two pressing molds 22 are arranged on the conveyor belt 1 behind two curling pieces 21, so The pressing mold 22 forms a tendency to rotate around its center line, and the rotation directions of the two pressing molds 22 are opposite;

[0059] The peeling blade surface 211 and the peeling groove 212 are arranged on the peeling block 21; the peeling blade surface 211 is a spiral surface, the front end of the peeling blade surface 211 is a horizontal edge, and the peeling blade surface 211 The rear end is a vertical e...

Embodiment 3

[0077] Such as Figure 1 to Figure 7 As shown: the dumpling machine forming module of the present invention includes: a conveyor belt 1 and a dumpling pressing mechanism, and a dumpling pressing mechanism is fixed above the conveyor belt 1, and the dumpling pressing mechanism includes: a skin rolling block 21 and a pressing mechanism Closing mold 22; described curling piece 21 has two, and two curling pieces 21 are symmetrically fixed on the top of conveyer belt 1, two pressing molds 22 are arranged on the conveyor belt 1 behind two curling pieces 21, so The pressing mold 22 forms a tendency to rotate around its center line, and the rotation directions of the two pressing molds 22 are opposite;

[0078] The peeling blade surface 211 and the peeling groove 212 are arranged on the peeling block 21; the peeling blade surface 211 is a spiral surface, the front end of the peeling blade surface 211 is a horizontal edge, and the peeling blade surface 211 The rear end is a vertical e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com