Yoghourt-containing ice cream capable of being stored at normal temperature, preparation method thereof and preparation method of yoghourt

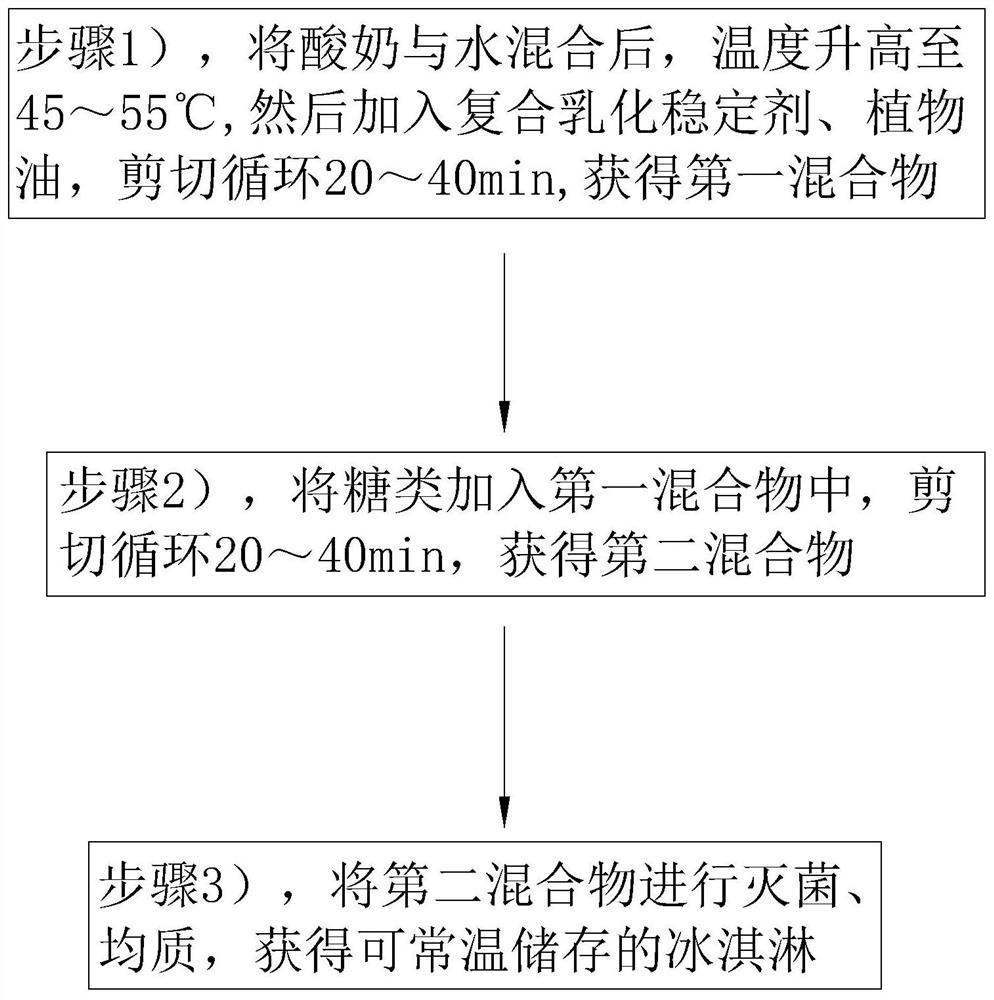

A technology for storage at room temperature and ice cream, which is applied to dairy products, dairy products, frozen desserts, etc., can solve the problems of ice cream that is no longer delicate and smooth, easy to damage the structure of ice cream, and high transportation costs, and achieves soft and smooth texture and delicate taste. , the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

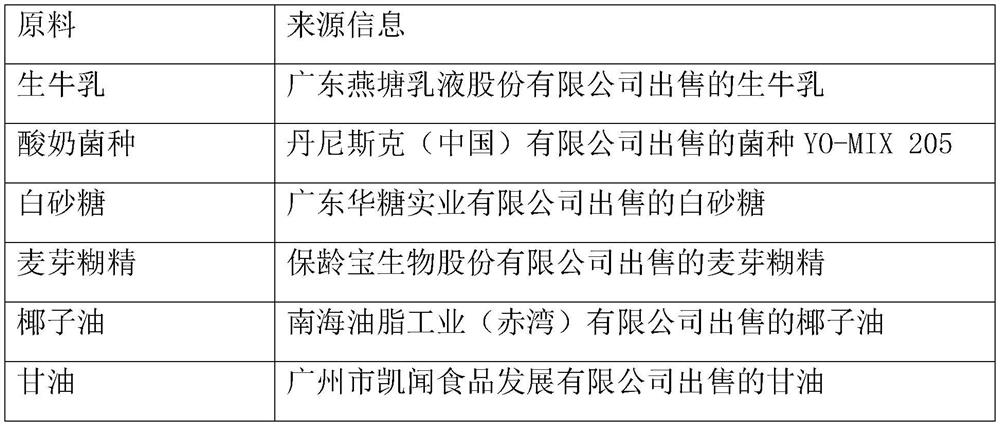

[0078] The embodiment of the present application discloses a kind of yoghurt, comprises following components:

[0079] Raw milk, yogurt strains.

[0080] The yogurt strain is strain YO-MIX 205.

[0081] In embodiment 1-3, the input amount of each component sees table 2 for details

[0082] Table 2

[0083] Example 1 Example 2 Example 3 Raw milk / Kg 1000 1000 1000 Yogurt strain / DCU 100 120 150

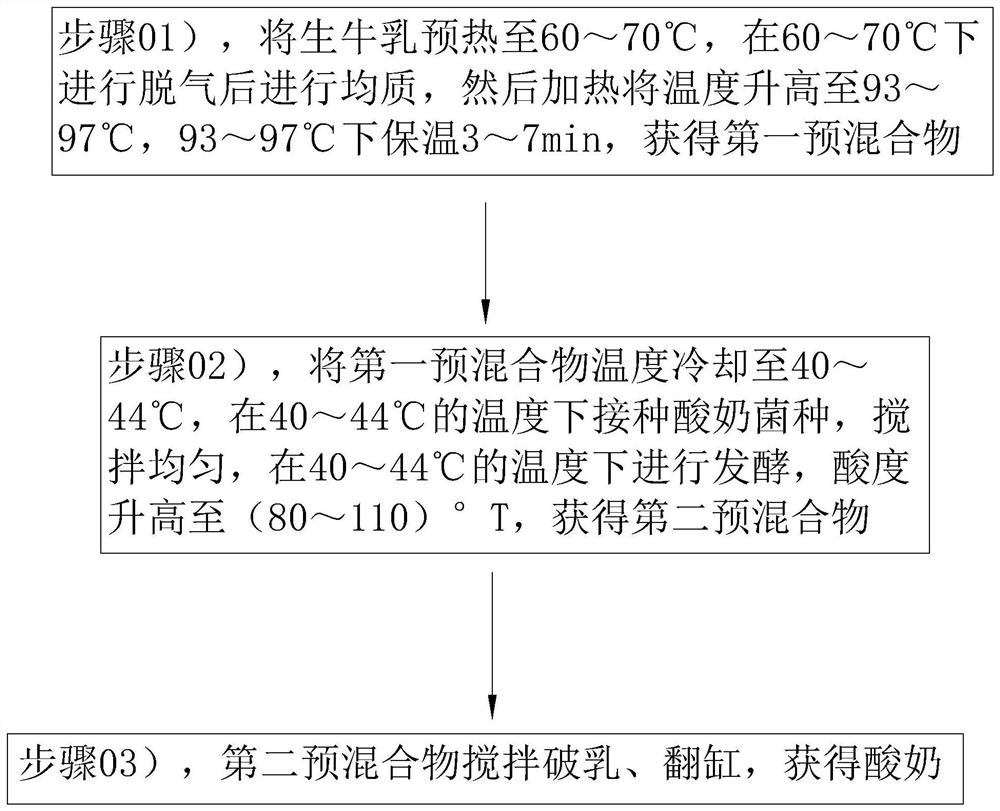

[0084] refer to figure 1 , the preparation method of yogurt comprises the following steps:

[0085] Step 01), put the raw milk into the preheating tank to preheat to 65°C, degas it through the degassing tank at 65°C at a pressure of 0.8bar, and then enter the homogenizer, at a temperature of 65°C, the second stage The homogenization pressure is 40 bar, and the first-stage homogenization pressure is 200 bar, and the homogenization is carried out for 5 seconds, and then the temperature is raised to 95 ° C through a plate heat exchanger, and steriliz...

Embodiment 4

[0090] The embodiment of the present application discloses yoghurt.

[0091] Compared with embodiment 2, the difference only lies in:

[0092] In the preparation method of yogurt:

[0093] Step 01), put the raw milk into the preheating tank to preheat to 60°C, degas it through the degassing tank at 60°C at a pressure of 0.6bar, and then enter the homogenizer, at a temperature of 60°C, the second stage The homogenization pressure is 35 bar, and the first-stage homogenization pressure is 180 bar, and the homogenization is carried out for 4 seconds, and then the temperature is raised to 93 ° C through a plate heat exchanger, and sterilized at 93 ° C for 5 minutes to obtain the first premixture;

[0094] Step 02), put the first premix into the first stirring tank, after the first premix is cooled to 40°C, inoculate the strain YO-MIX 205 at a temperature of 40°C, and stir for 15min at a rotation speed of 40r / min , stirred evenly, and then fermented at a temperature of 40 ° C, a...

Embodiment 5

[0098] The embodiment of the present application discloses yoghurt.

[0099] Compared with embodiment 2, the difference only lies in:

[0100] In the preparation method of yogurt:

[0101] Step 01), put the raw milk into the preheating tank to preheat to 70°C, pass through the degassing tank at 70°C for degassing at a pressure of 0.5 bar, and then enter the homogenizer, at a temperature of 70°C, the second stage The homogenization pressure is 50 bar, and the first-stage homogenization pressure is 220 bar, and the homogenization is carried out for 6 seconds, and then the temperature is raised to 97 ° C through a plate heat exchanger, and sterilized at 97 ° C for 5 minutes to obtain the first premixture;

[0102] Step 02), put the first premix into the first stirring tank, cool the first premix to 44°C, inoculate the yogurt strain YO-MIX 205 at a temperature of 44°C, and stir at a rotation speed of 40r / min 12min, stir evenly, then keep the temperature of 44°C for fermentation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com