Biological filtration equipment for centralized treatment of waste gas of wastewater station

A centralized treatment and biological filtration technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems such as the decline of the filtration effect of the filter layer, and achieve the effect of accelerating the air-drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

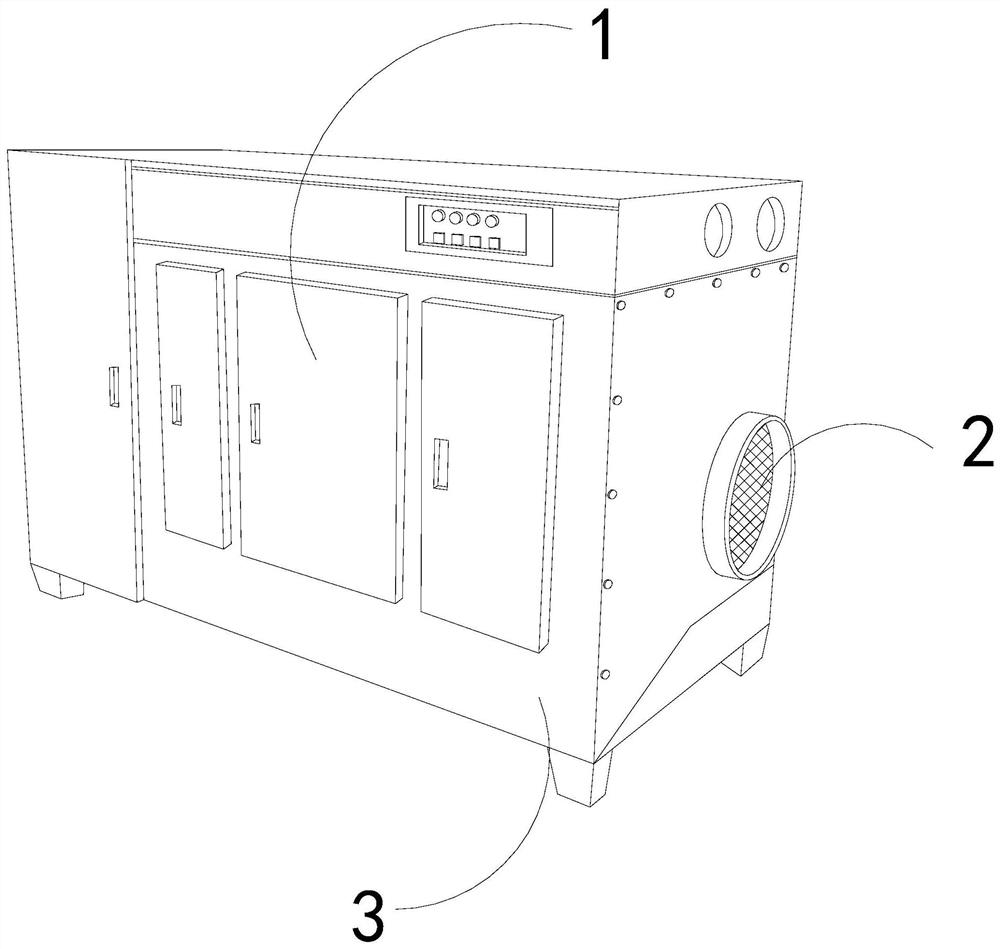

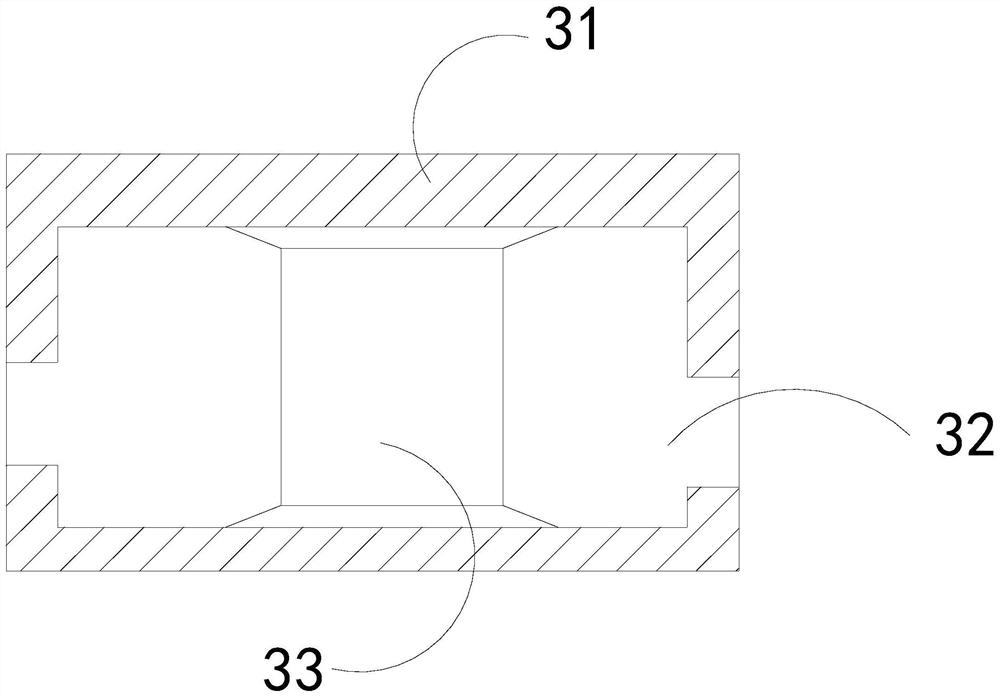

[0027] The invention provides a kind of biological filtration equipment for centralized treatment of waste gas in a waste water station. Its structure includes a sealed door 1, an air inlet 2, and a body 3. The mouth 2 is an integrated structure; the body 3 includes an outer frame 31, an inner cavity 32, and a filter layer 33. The inner cavity 32 and the outer frame 31 are an integrated structure, and the filter layer 33 is embedded in the outer frame 31. internal location.

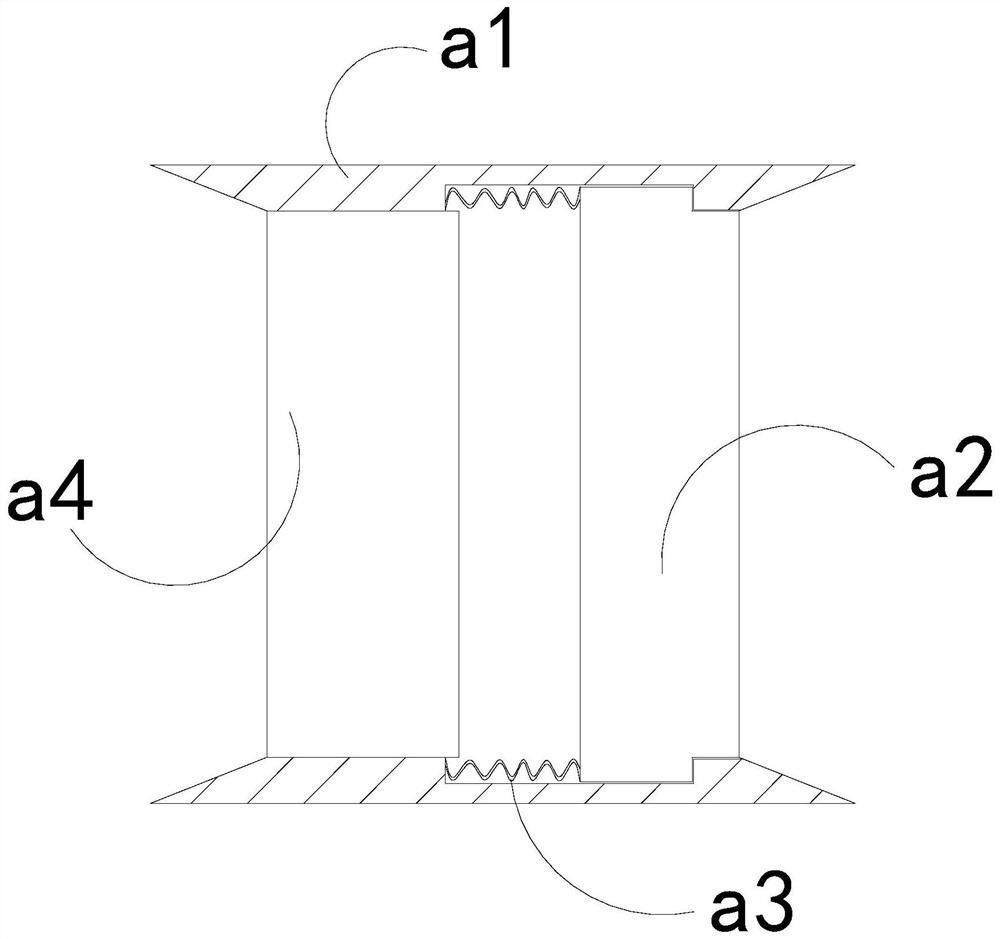

[0028] Wherein, the filter layer 33 includes a guide plate a1, a force plate a2, an elastic strip a3, and a fixed plate a4, the force plate a2 is movably engaged with the guide plate a1, and the elastic strip a3 is installed on the force plate a2 and fixed Between the plates a4, the exhaust gas generates an inward thrust on the force plate a2, which can make the force plate a2 slide inward along the guide plate a1 and shrink, and the force plate t...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the fixed plate a4 includes a blocking block c1, a swinging plate c2, an air collecting chamber c3, and an connecting plate c4. The blocking block c1 is embedded in the right side of the air collecting chamber c3. The inner part of the chamber c3 is movable and engaged, the gas-collecting chamber c3 and the connecting plate c4 are an integrated structure, and the swinging plate c2 is provided with three, which are evenly distributed in parallel inside the connecting plate c4, and the connecting plate is hit by a mechanism The vibration generated by c4 can make the oscillating plate c2 swing along the connecting plate c4, thereby generating an airflow to accelerate the drying speed of the moisture inside the connecting plate c4.

[0036] Wherein, the blocking block c1 includes an outer sliding plate c11, a connecting piece c12, and a transition block c13. The connecting piece c12 is installed between two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap