Universal automatic pipe making machine

An automatic and general-purpose technology, applied in the field of general-purpose automatic pipe-making machines, can solve the problems of high manufacturing cost, time-consuming, and difficult work of changing molds, and achieve high equipment automation, high pipe straightness, and general-purpose high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, invention is described in further detail.

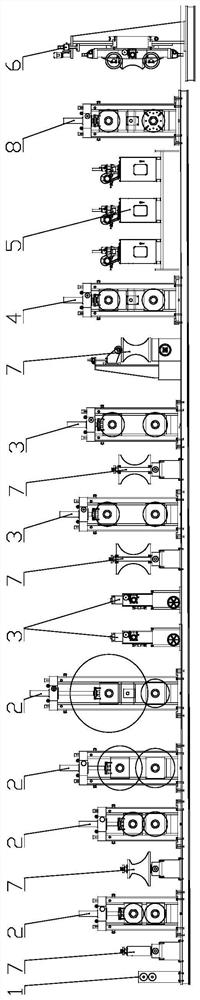

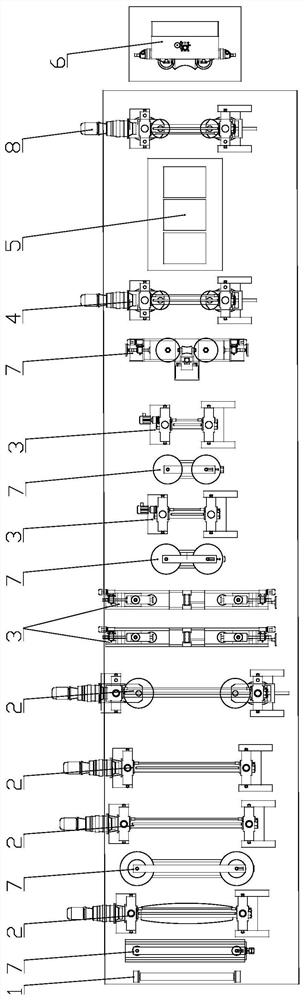

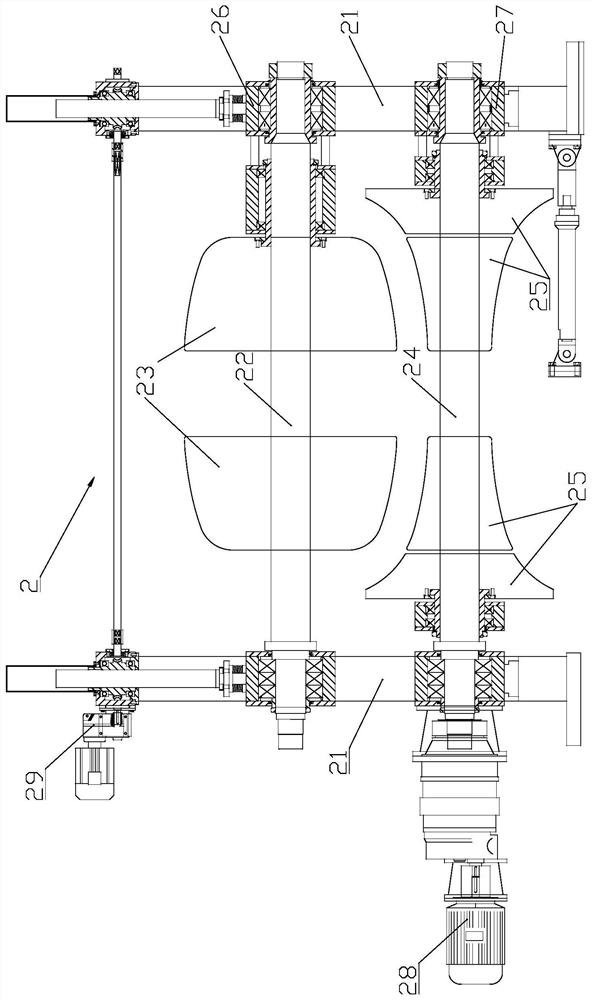

[0028] Figure 1 to Figure 13 A general-purpose automatic pipe making machine according to an embodiment of the present invention is schematically shown.

[0029] refer to Figure 1 ~ Figure 2 The general-purpose automatic pipe making machine includes steel strip pinch device 1, horizontal rolling device 2, closing rolling device 3, shaping device 4, automatic grinding device 5, orthopedic sizing device 8, straightening device 6, steel strip limiter Bit device 7, welding device and PLC control device. Steel strip pinch device 1, horizontal rolling device 2, closing rolling device 3, shaping device 4, automatic grinding device 5, orthopedic sizing device 8 and straightening device 6 are arranged in sequence, and the steel strip limiting device 7 is set to multiple One and distributed between the belt pinch device 1, the horizontal rolling device 2, the closing rolling device 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com