Spindle cooling device for numerically-controlled machine tool

A technology for CNC machine tools and cooling devices, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., and can solve the problems of poor spindle cooling effect and low efficiency of cooling source use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

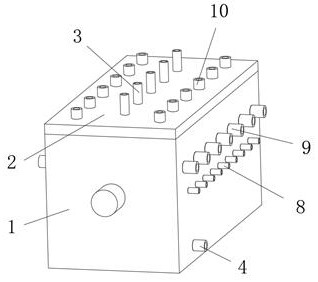

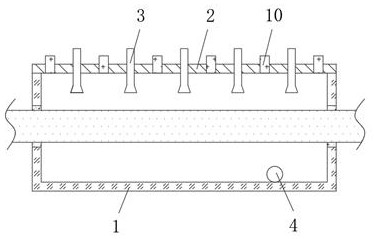

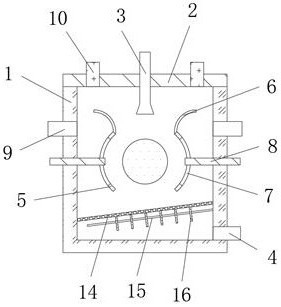

[0026] refer to Figure 1-4 , a spindle cooling device for a CNC machine tool, comprising a cooling box 1, the middle position between the two sides of the cooling box 1 is rotatably connected to the main shaft, the top of the cooling box 1 is fixed with a cover plate 2, and the top of the cover plate 2 is fixed with a horizontal The nozzles 3 are distributed equidistantly in the direction, the bottom end of the cooling box 1 is fixed with a liquid discharge pipe 4, and the two ends of the main shaft are fixed with arc-shaped stoppers 5 between the inner walls on both sides of the cooling box 1, and the stoppers The middle position of 5 is set to arch toward the end away from the main shaft, and the top of the limiter 5 is fixed with an arc-shaped flow guide 6, and the flow guide 6 is inclined upward toward the end far away from the main shaft, and the middle of the flow guide 6 The position is arched toward the end close to the main shaft, and both ends of the top of the cove...

Embodiment 2

[0030] refer to Figure 1-5 , a spindle cooling device for a CNC machine tool, the bottom between the inner walls of the two ends of the cooling box 1 is fixed with a filter screen plate 14 placed obliquely, and the filter screen plate 14 is inclined downward toward the end away from the drain pipe 4, the cooling box 1 One end close to the drain pipe 4 is located at the bottom of the filter screen plate 14, and a partition plate 15 is fixed. The inclination direction of the partition plate 15 and the filter screen plate 14 is the same. leave a gap;

[0031] The top outer wall of the partition 15 is fixed with cooling fins 16 distributed equidistantly, and the middle position of the cooling fins 16 is set to be arched towards the end close to the drain pipe 4, and the cooling fins 16 on the partition 15 are arranged to be distributed at intervals. The outer wall of one end of the heat sink 16 is located at the top and bottom of the partition 15 and is provided with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com