UV printing machine

A technology of printing machine and body, applied in printing machine, rotary printing machine, printing and other directions, can solve the problems of discontinuous processing, difficult to cooperate with UV printing machine tacitly, and the efficiency of UV printing machine is reduced, so as to improve processing efficiency and processing. quality, improve the regularity of feeding, and improve the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

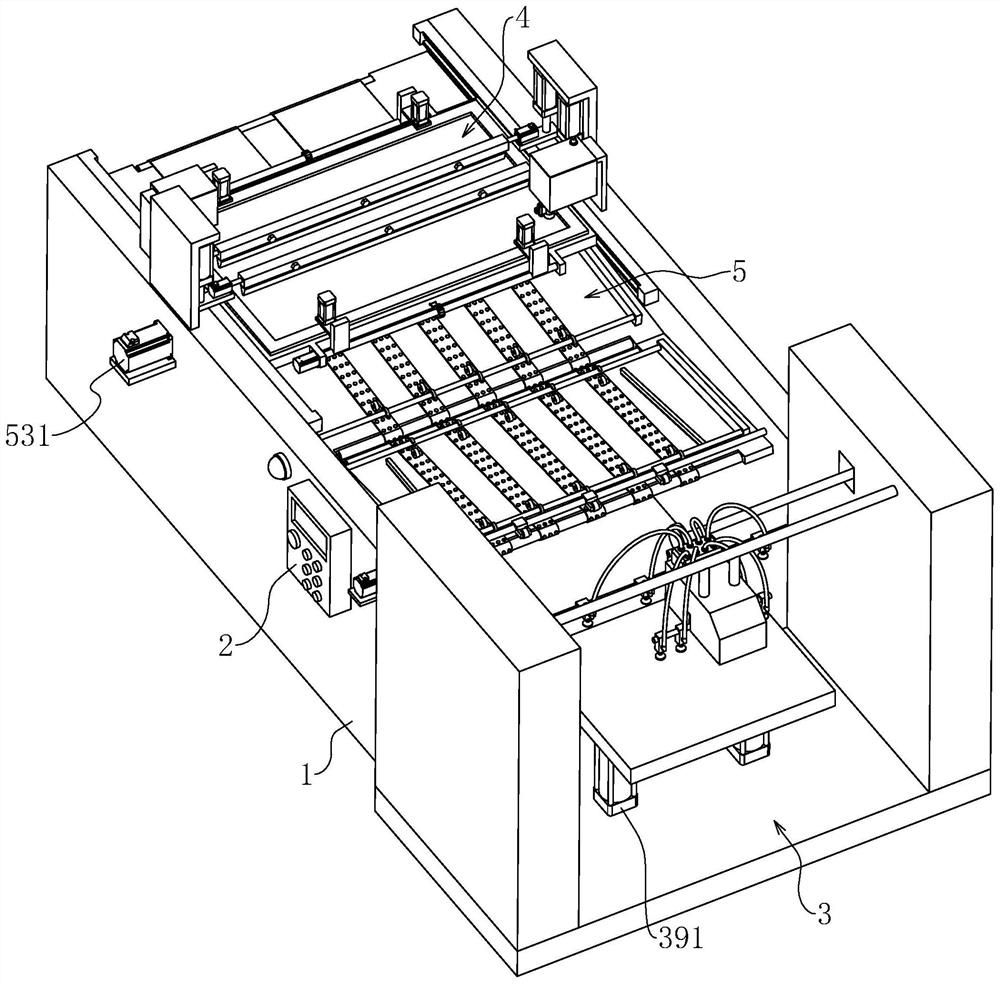

[0056]The embodiment of the application discloses a UV printer. Referencefigure 1 , The UV printer includes a body 1, a controller 2, a feeding mechanism 3, a template fixing mechanism 4 and a material transfer mechanism 5 for conveying to-be-printed products. The controller 2 is connected to the body 1, and is set as a PLC control system. The feeding mechanism 3 moves the stacks of to-be-printed products to the feeding mechanism 5 one by one, and the feeding mechanism 5 drives the to-be-printed matter through the template fixing mechanism 4 so that the to-be-printed matter is separated from the UV printer after being printed. The template fixing mechanism 4 is used to fix the template and transfer the specific pattern on the template to the to-be-printed product to realize the printing process of the to-be-printed product.

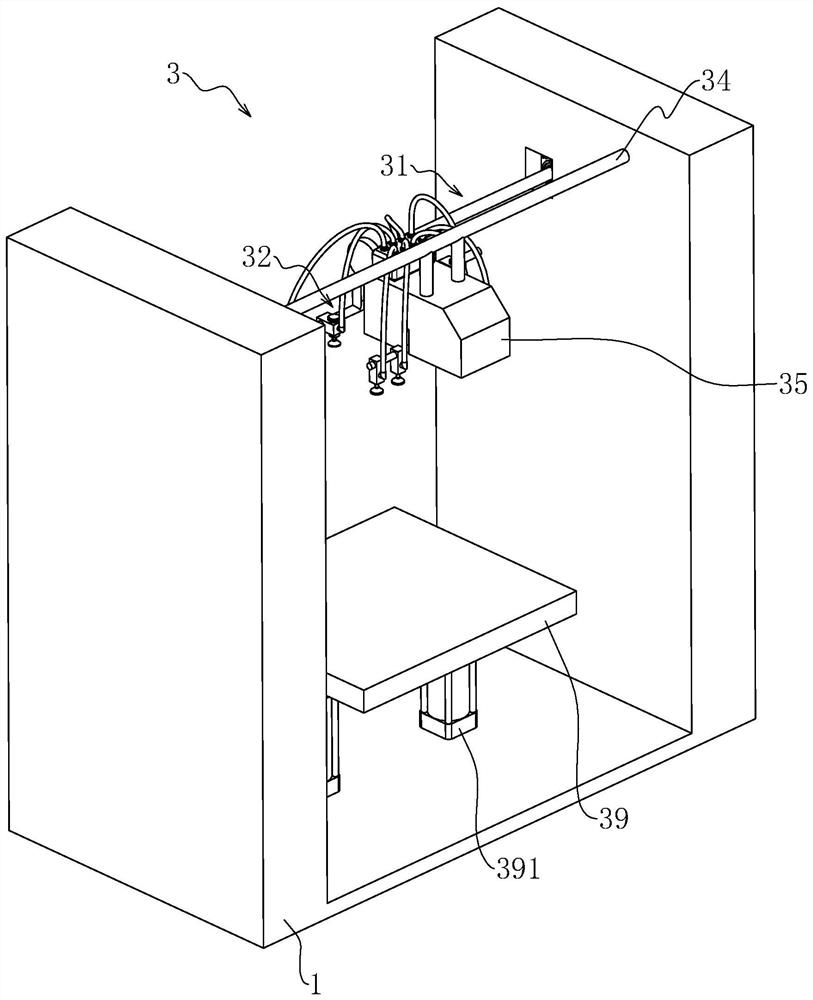

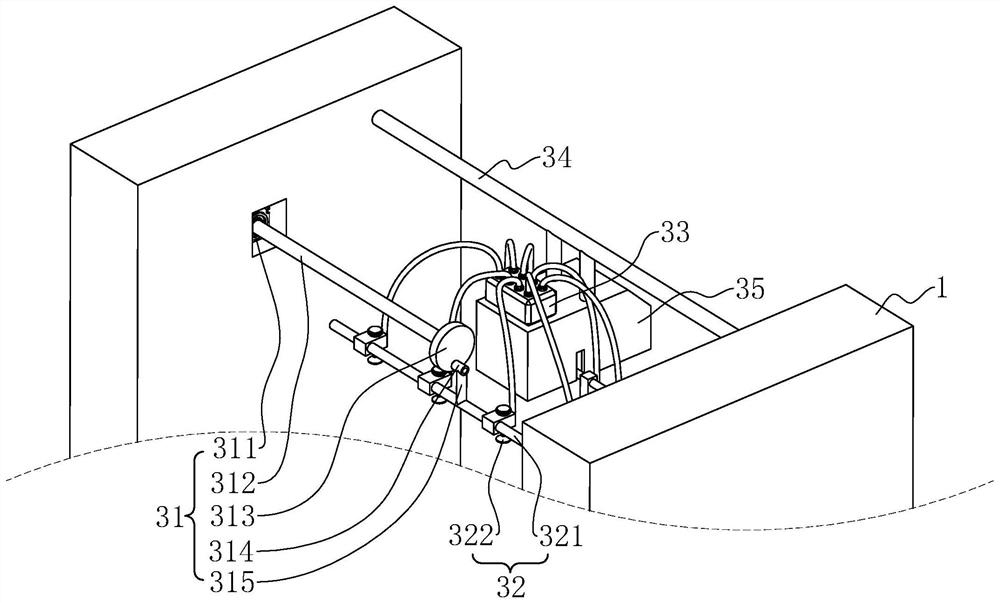

[0057]Referencefigure 2 , The feeding mechanism 3 includes a clamping drive assembly 31, a clamping assembly 32 and a tray 39. The lower end of the tray 39 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com