An automobile leaf spring suspension system with integrated brake air cylinder

A technology of spring suspension and automobile steel plate, which is applied to vehicle springs, elastic suspensions, springs, etc., can solve the problems of difficult layout and poor versatility, and achieve the effects of flexible layout, easy installation and high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

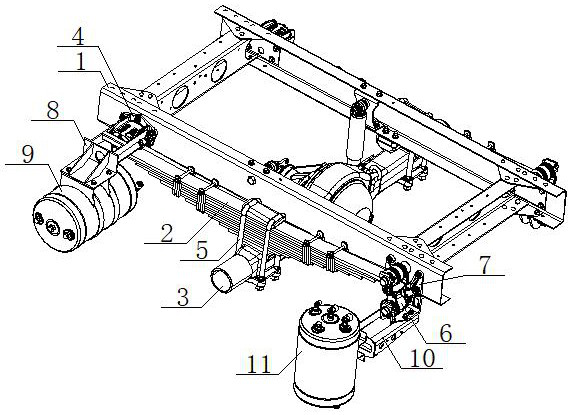

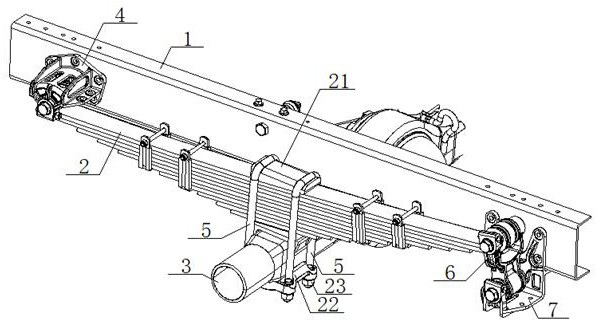

[0052] see figure 1 , figure 2 , an automobile leaf spring suspension system integrated with a brake air cylinder, comprising a vehicle frame 1, a leaf spring assembly 2 and an axle 3, the front end of the leaf spring assembly 2 is connected to the vehicle frame 1 through a fixed end support 4 The middle part of the leaf spring assembly 2 is connected with the axle 3 through the U-shaped bolt 5, the rear end of the leaf spring assembly 2 is connected with the upper part of the movable lifting lug 6, and the lower part of the movable lifting lug 6 is supported by the movable end. The seat 7 is connected with the vehicle frame 1, the fixed end support 4 is connected with the front air storage tank support 8, the front air storage tank support 8 is connected with the front air storage tank 9 in a horizontal arrangement, and the movable end support The seat 7 is connected with the rear air storage tank support 10, and the rear air storage tank support 10 is connected with the re...

Embodiment 2

[0054] Basic content is the same as embodiment 1, the difference is:

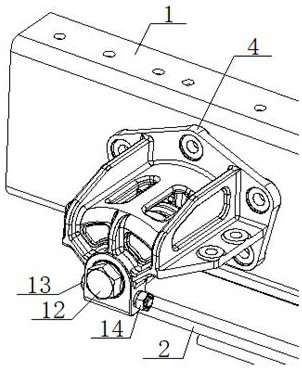

[0055] see figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9, the fixed end support 4 includes a No. 1 riser 41, a No. 2 riser 42 and a No. 3 riser 43. The No. 1 riser 41 is connected to the side of the vehicle frame 1, and the lower part of the No. 1 riser 41 A first mounting boss 44 is provided, and a first threaded hole 45 is provided on the first mounting boss 44. One end of the second vertical board 42 and the third vertical board 43 is connected with the first vertical board 41, and the second vertical board 43 is connected with the first vertical board 41. A second installation boss 46 is connected between the other end of the vertical board 42 and the other end of the third vertical board 43, the second installation boss 46 is provided with a first installation hole 47, and the first installation hole 47 is sleeved with a first installation boss 46. ...

Embodiment 3

[0057] Basic content is the same as embodiment 1, the difference is:

[0058] see figure 1 , figure 2 , Figure 4 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , the movable end support 7 includes No. 5 vertical plate 71 and No. 5 horizontal plate 72 and No. 6 horizontal plate 73 connected on both sides thereof. The No. 5 vertical plate 71 is connected with the side of vehicle frame 1, and No. 5 The vertical plate 71 is provided with a third mounting boss 74, and the third mounting boss 74 is provided with a second threaded hole 75. The fifth horizontal plate 72 is connected with the lower wing surface of the vehicle frame 1, and the sixth horizontal plate The end of the plate 73 away from the No. 5 vertical plate 71 is provided with a fourth mounting boss 76, the fourth mounting boss 76 is provided with a third mounting hole 77, and the third mounting hole 77 is fitted with a second pin sleeve 78. The fixed pin shaft 17 is connected with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com