Single-piece separation system

A separation system and single-piece technology, applied in the direction of conveyor objects, conveyor control devices, conveyors, etc., can solve the problems of high cost of servo motors, insufficient structural layout, and difficult single-piece separation, etc., to achieve reliable transmission wear, Compact and reasonable structure, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is further described below in conjunction with specific embodiments:

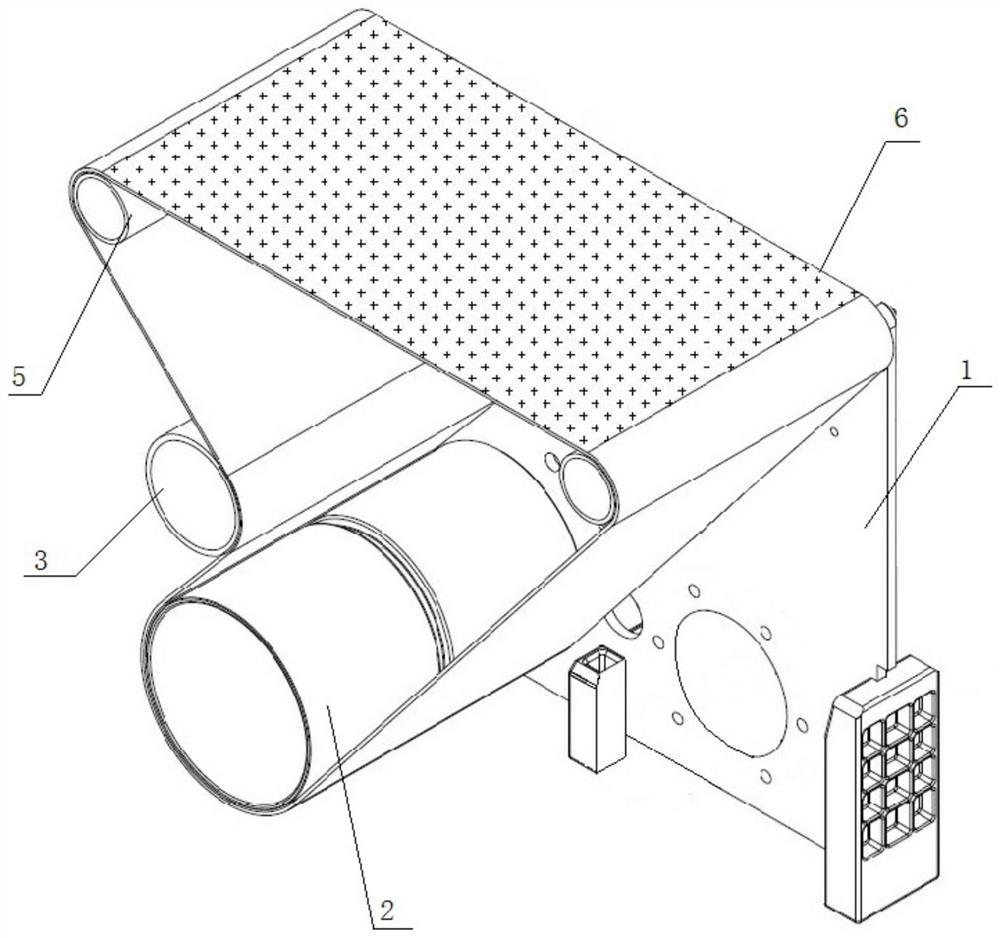

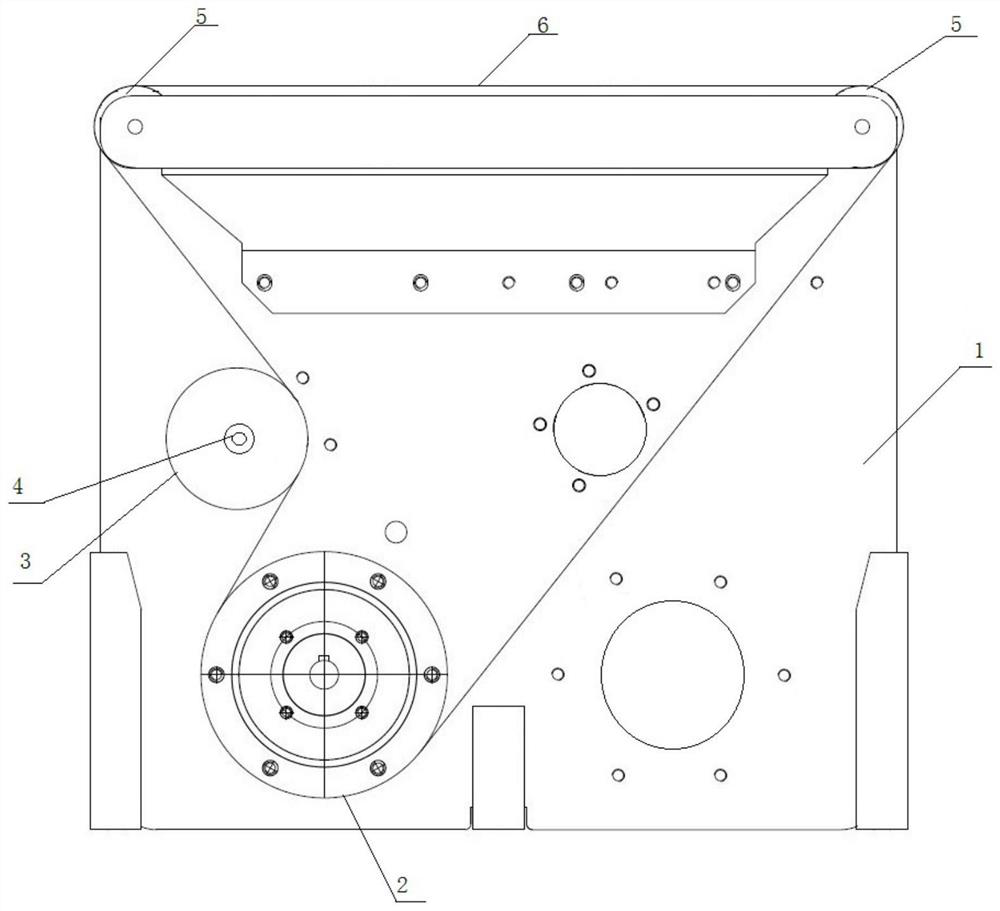

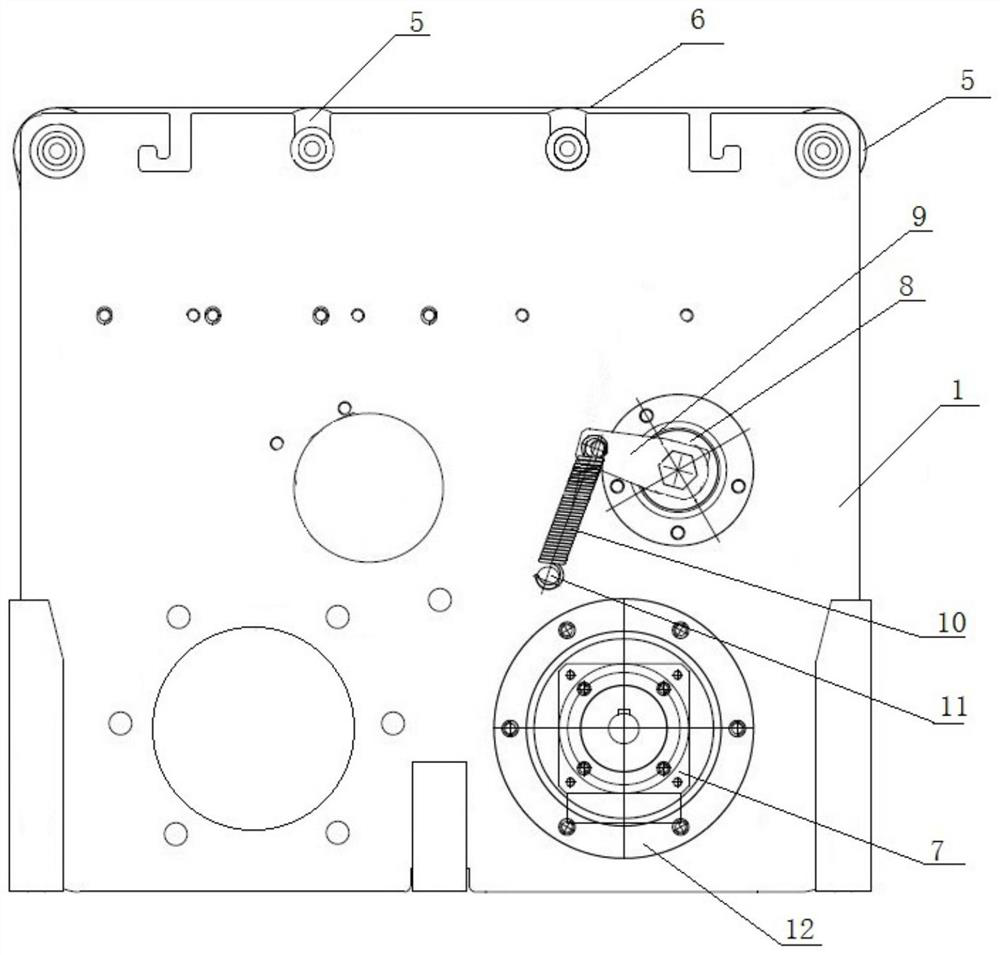

[0037] A new type of stable and high-precision separation module is characterized in that its structure includes a dispersion device 18, a separation unit 21, an arrangement device 19, and a flow distribution device 20 arranged in sequence, and the front end of the separation unit 21 is provided with a dispersion device 18, and the dispersion device 18 can be a scattering belt conveyor, and the rear end of the separation unit 21 is provided with an arrangement device 19, and the arrangement device 19 is an inclined roller machine, and the rear end of the arrangement device 19 is provided with a splitter device 20, and the conveying direction is from the dispersion device 18 to shunt device 20, such as Figure 6 shown. Separation unit 21 is made up of several separators, separators include drive system, conveyor belt 6, main frame 1, conveyor belt autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com