Automatic moving hanging rack for electronic part production and using method

An electronic component, automatic moving technology, applied in transportation and packaging, conveyors, non-mechanical conveyors, etc., can solve problems such as high cost and inability to make full use of factory space, and achieve the effect of stable model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

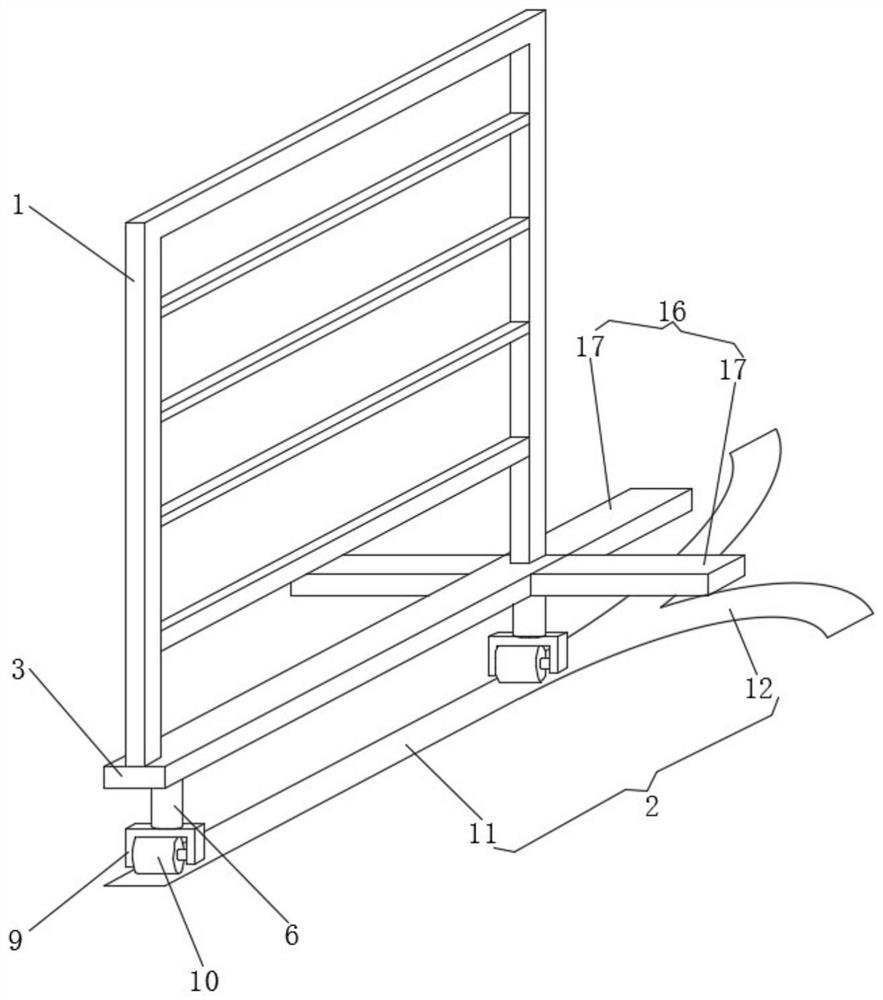

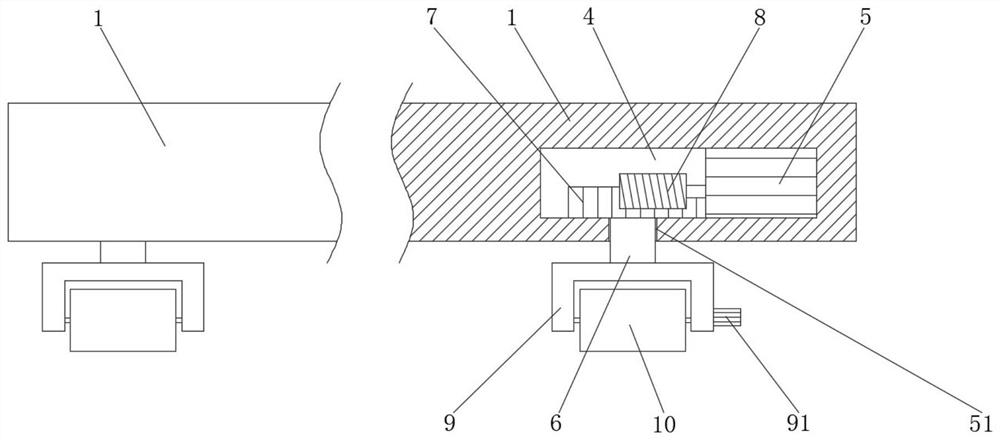

[0024] see Figure 1-4 , the present embodiment provides an automatic mobile hanger for the production of electronic parts, including a fixed frame 1 and a magnetic track 2, the bottom end of the fixed frame 1 is fixed with a crossbar 3, and an installation warehouse is provided inside one end of the crossbar 3 4. The steering motor 5 is installed inside the installation bin 4, and the inner wall of the bottom side of the installation bin 4 is provided with a rotating hole 51, and a rotating shaft 6 is installed inside the rotating hole 51, and a gear 7 is fixed on the top of the rotating shaft 6 inside the installation bin 4 , the power output shaft of the steering motor 5 meshes with the gear 7 through the screw mandrel 8. The screw mandrel 8 can not only realize the rotation of the gear 7, but also can realize the fixing effect on the gear 7 when the steering motor 5 is not excited, and can avoid the occurrence of a fixed frame. 1 Deviate from the track 2 direction movement...

Embodiment 2

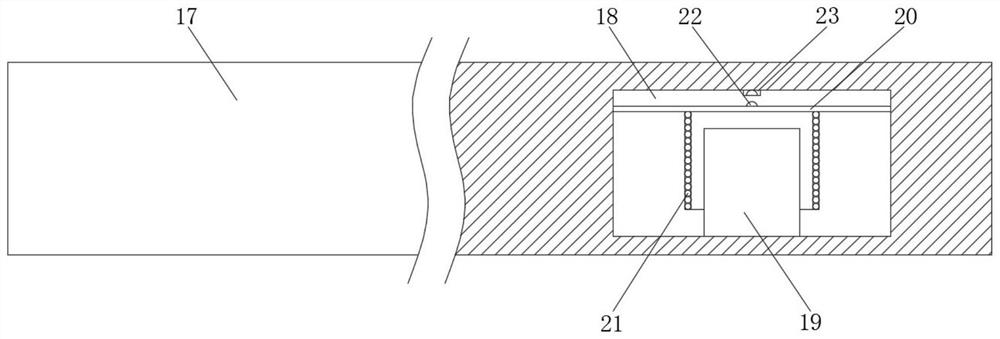

[0036] see figure 2 , On the basis of embodiment 1, a further improvement has been made: the inner wall of the bottom side of the equipment compartment 18 is fixed with a magnet 19, and the inner wall of the top side of the equipment compartment 18 is provided with a stretchable film 20 directly above the magnet 19, and the stretchable film 20 is close to the magnet 19 An induction coil 21 is fixed on one side, and the magnet 19 can apply magnetic forces in different directions to the induction coil 21 that generates an induced magnetic field, so that the stretchable film 20 can vibrate inside the equipment compartment 18, so that the contact 22 and the connection point 23 can be The frequency of the alternating current is contacted, so that the single-chip microcomputer 15 can obtain a high-level signal with a fixed frequency, and the signal at the information input end of the single-chip microcomputer 15 can be more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com