Polymer cement waterproof coating and preparation method thereof

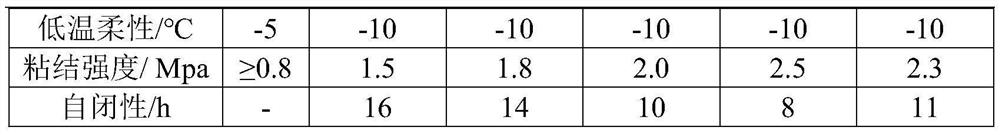

A waterproof coating and polymer technology, applied in the field of architectural waterproof coatings, can solve the problems of coating waterproof ability decline, waterproof layer damage, poor crack resistance, etc., and achieve the effects of short drying time, good low temperature performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

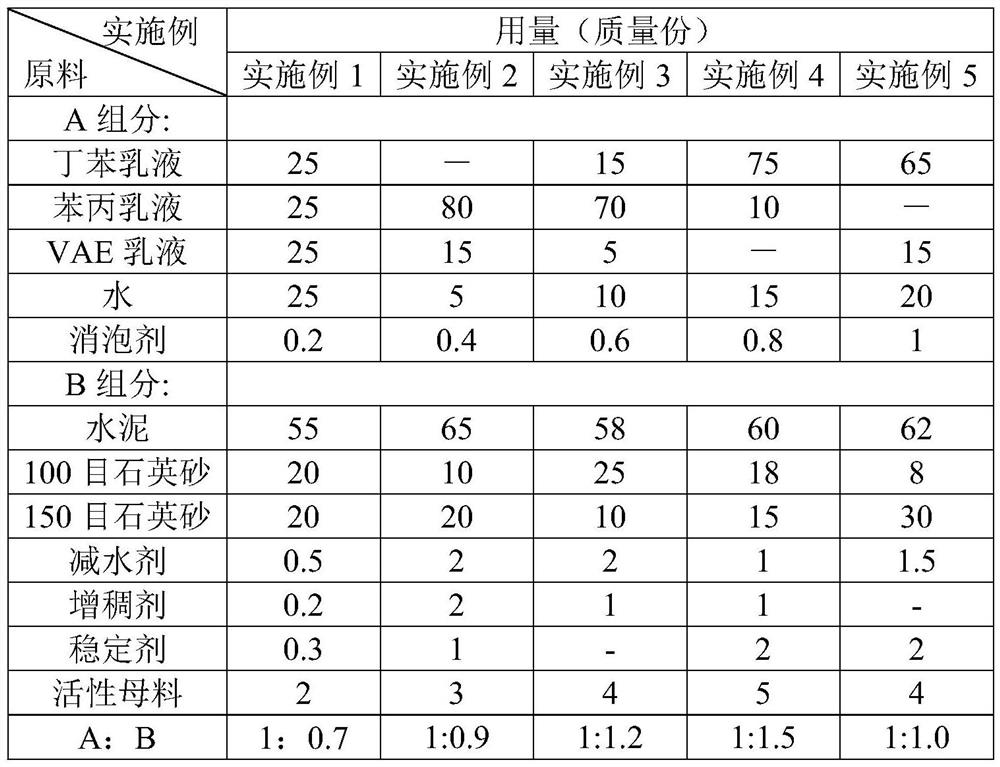

[0027] The polymer cement waterproof coating of this embodiment is composed of component A and component B. The raw materials, dosages and proportions of components A and B in components A and B are shown in Table 1.

[0028] The modified emulsion of this embodiment is a styrene-acrylic emulsion, which is purchased from the market and purchased from Bardford Company.

[0029] The defoamer of this embodiment is a water-based defoamer, which is self-made.

[0030] The cement of this embodiment is 42.5R type, purchased from the market, purchased from Conch Cement Company.

[0031] The quartz sand in this embodiment includes two particle sizes of 100 mesh and 150 mesh, purchased from the market, and purchased from Guangdong Qingyuan Quartz Sand Company.

[0032] The additives in this embodiment include water reducer, thickener and stabilizer, which are purchased from the market and purchased from Guangzhou Kehua Chemical Company.

[0033] The active masterbatch of this embodimen...

Embodiment 2

[0039] The polymer cement waterproof coating of this embodiment is composed of component A and component B. The raw materials, dosages and proportions of components A and B in components A and B are shown in Table 1.

[0040] The modified emulsion in this embodiment is styrene-acrylic emulsion and VAE emulsion, which are purchased from the market and purchased from Bardford Company.

[0041] The defoamer of this embodiment is a water-based defoamer, which is self-made.

[0042] The cement of this embodiment is 42.5R type, purchased from the market, purchased from Conch Cement Company.

[0043] The quartz sand in this embodiment includes two particle sizes of 100 mesh and 150 mesh, purchased from the market, and purchased from Guangdong Qingyuan Quartz Sand Company.

[0044] The additives in this embodiment include water reducer, thickener and stabilizer, which are purchased from the market and purchased from Guangzhou Kehua Chemical Company.

[0045] The active masterbatch o...

Embodiment 3

[0048] The polymer cement waterproof coating of this embodiment is composed of component A and component B. The raw materials, dosages and proportions of components A and B in components A and B are shown in Table 1.

[0049] The modified emulsion in this embodiment is styrene-butadiene emulsion, styrene-acrylic emulsion and VAE emulsion, which are purchased from the market and purchased from Bardford Company.

[0050] The defoamer of this embodiment is a water-based defoamer, which is self-made.

[0051]The cement of this embodiment is 42.5R type, purchased from the market, purchased from Conch Cement Company.

[0052] The quartz sand in this embodiment includes two particle sizes of 100 mesh and 150 mesh, purchased from the market, and purchased from Guangdong Qingyuan Quartz Sand Company.

[0053] The additives in this embodiment include water reducer and thickener, purchased from the market, purchased from Guangzhou Kehua Chemical Company.

[0054] The active masterbatch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com