Sealing element for cable joint, sealing element material formula and preparation method

A cable connection and sealing technology, which is applied to the parts, connections, electrical components, etc. of the connection device, can solve the problems of easy falling off of the connection seal, poor packaging of the battery core, and inconvenient packaging of the connection, so as to prolong the service life , flexible and convenient to use, good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

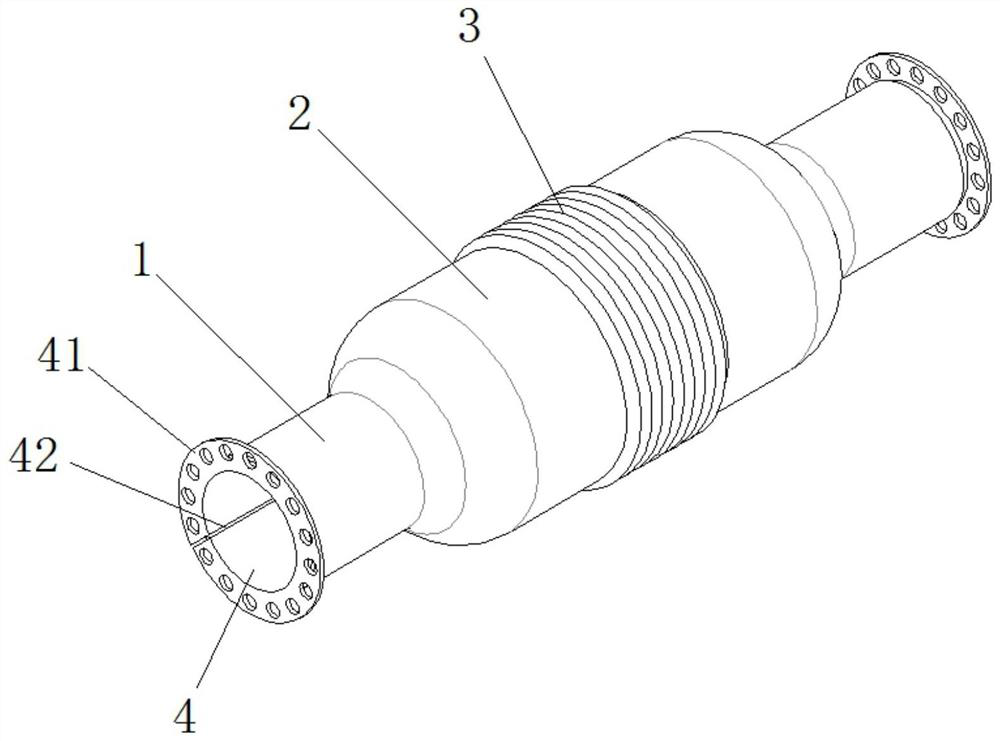

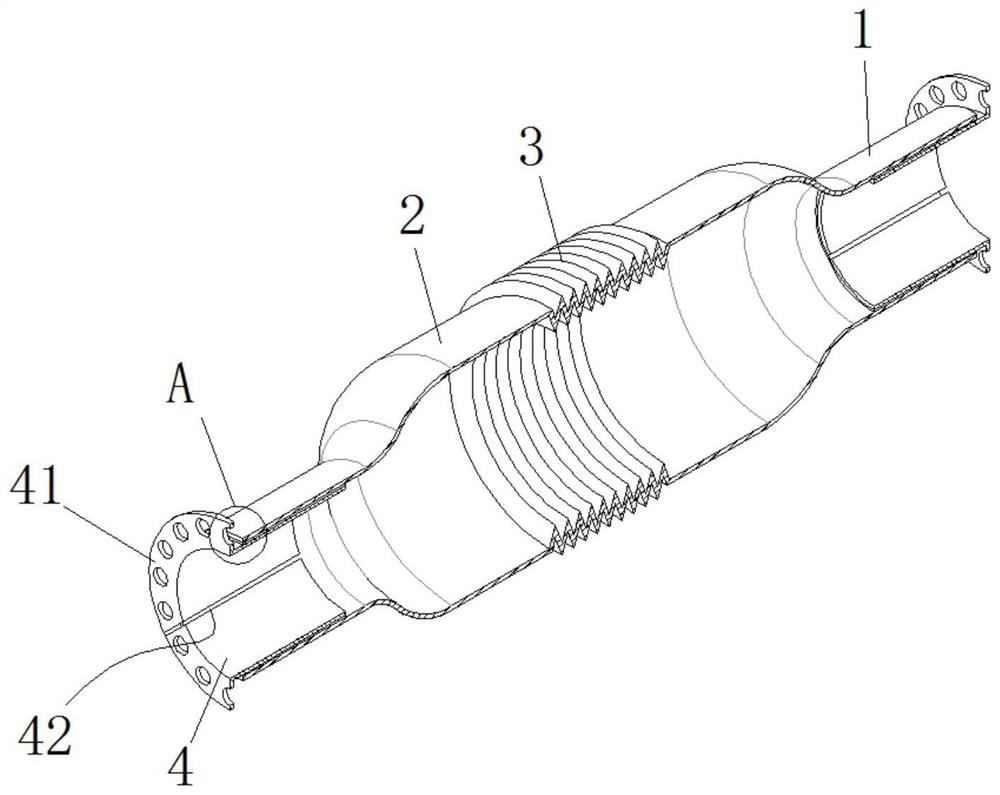

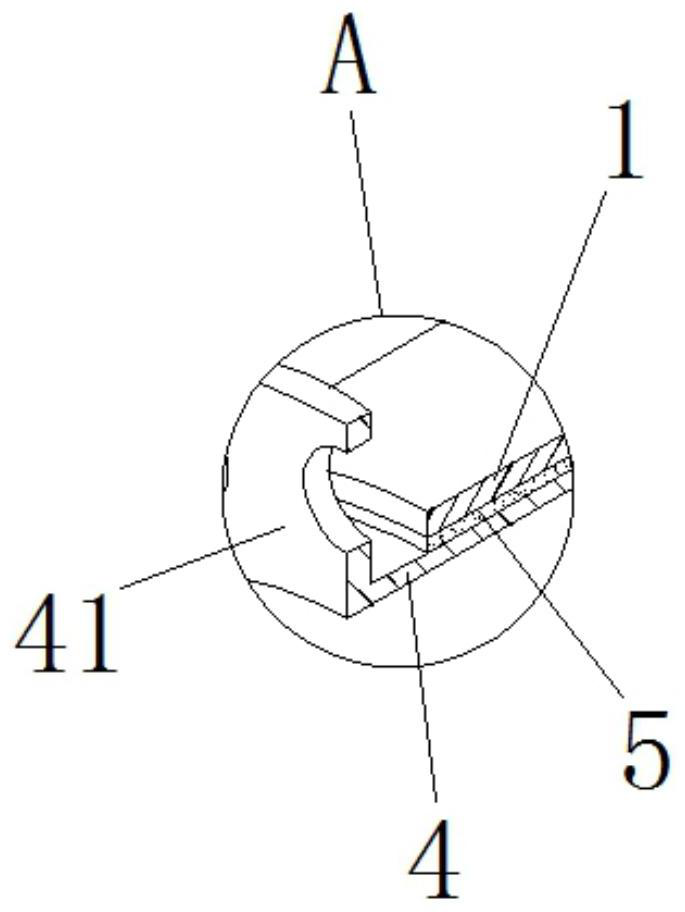

Image

Examples

Embodiment 1

[0041] The mass percentage of each component of the material formula of the seal is as follows:

[0042]

Embodiment 2

[0044] The optimal mass percentage of each component of the material formulation of the seal is as follows:

[0045]

Embodiment 3

[0047]The mass percentage of each component of the material formula of the seal is as follows:

[0048]

[0049] The present invention also provides a method for preparing a seal by using the formula of the seal material for the cable connection, the specific steps are as follows: 1) Weigh natural rubber, sulfur, magnesium oxide, magnesium hydroxide, tridecafluorooctyl trimethyl The raw materials of oxysilane, trioctyl trimellitate, anti-aging agent DPN1-2, bisphenol A and paraffin are used for standby;

[0050] 2) Mix natural rubber, sulfur, and magnesium oxide evenly, add to an internal mixer, and knead for 5-10 minutes, then mix magnesium hydroxide, tridecafluorooctyltrimethoxysilane, trioctyl trimellitate, Add anti-aging agent DPN1-2, bisphenol A, and paraffin into the internal mixer in turn, and stir while adding raw materials. After stirring evenly, knead for 5-10 minutes to obtain the rubber compound, and press the rubber compound on the open mixer. piece spare;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com