Maotai-flavor liquor brewing production device

A sauce-flavored liquor and production device technology, which is applied in the field of liquor brewing technology, can solve problems such as poor liquor production capacity, difficult gelatinization, and long liquor production time, so as to reduce manpower input, improve liquor quality, and benefit liquor products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

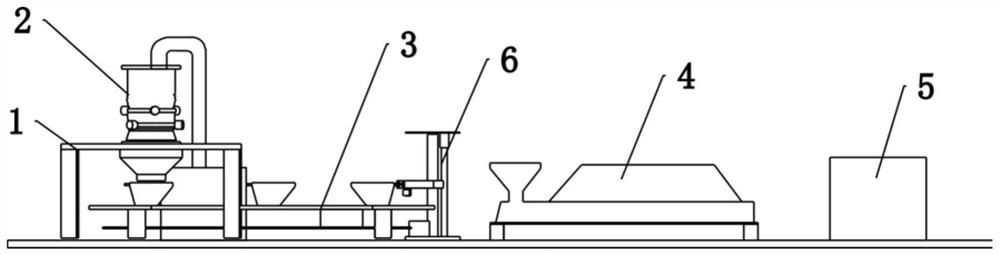

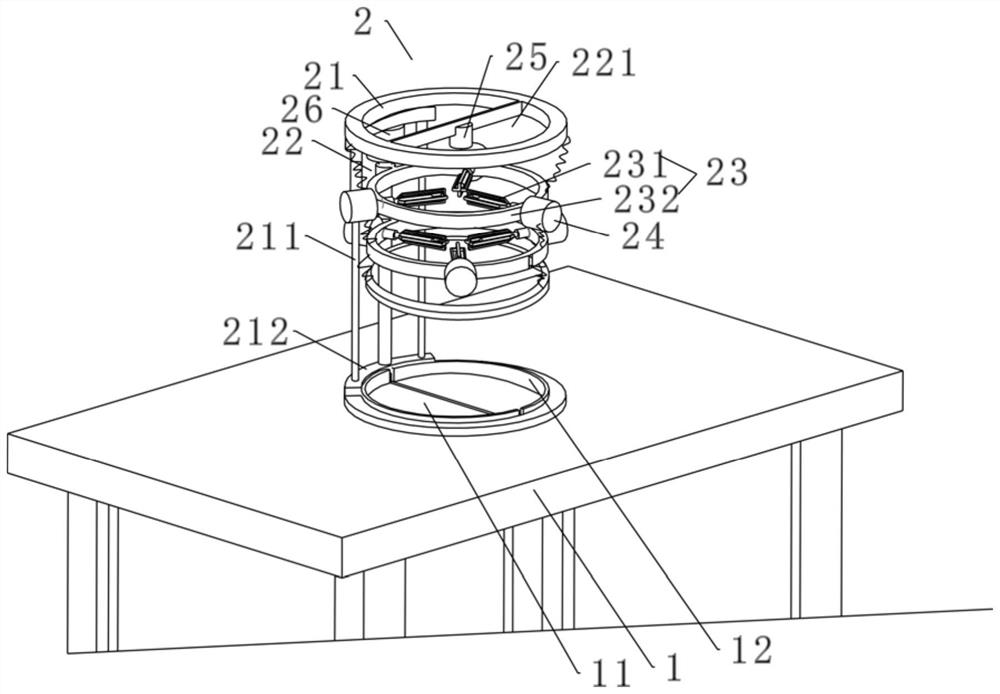

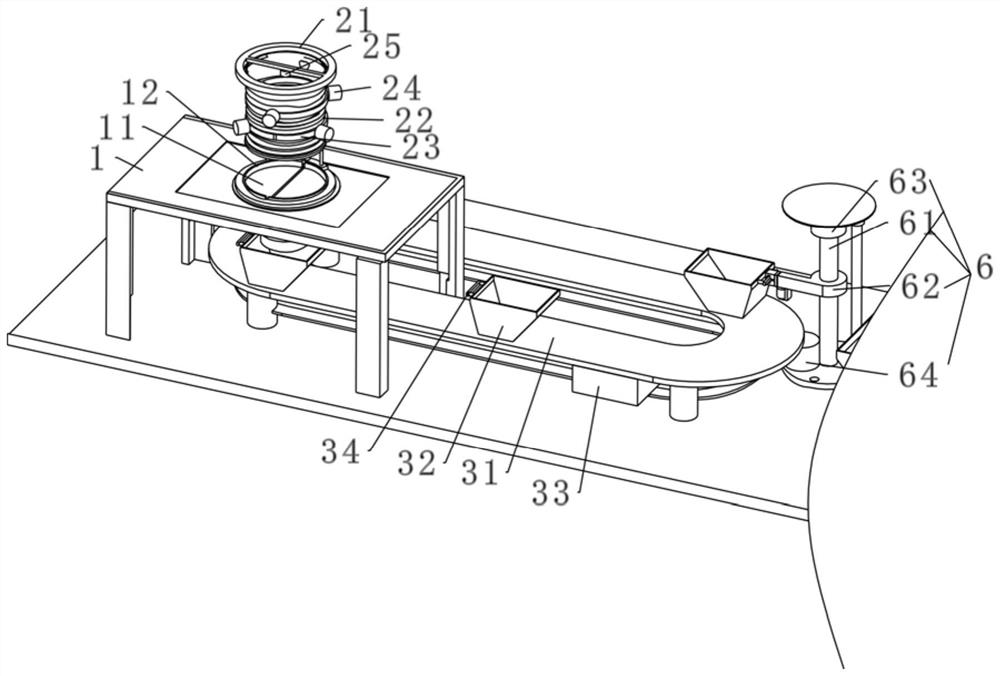

[0027] see Figure 1-Figure 3 , a typical embodiment of the present application provides a Maotai-flavored liquor brewing production device, which includes an operating table 1, a material turning mechanism 2 arranged on the operating table 1, a conveying mechanism 3, and an operating table 1 The cooking mechanism 4 on one side, the airing room and the fermentation room 5 integrated with the cooking mechanism 4 . The material turning mechanism 2 is arranged on the operating platform 1, and the conveying mechanism 3 is arranged on the lower part of the operating platform. Between the mechanism 2 and the cooking mechanism 4, in order to realize the transportation of materials, the turning mechanism 2 is correspondingly set directly above the operating position 11, and one end of the conveying mechanism 3 is correspondingly set directly below the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com