Mixer integration device, DPF system and vehicle

A technology of integrated devices and mixers, which can be used in mufflers, exhaust devices, machines/engines, etc., to solve problems such as fuel droplet leakage, and to increase exhaust pressure, increase exhaust temperature, increase flow rate and temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

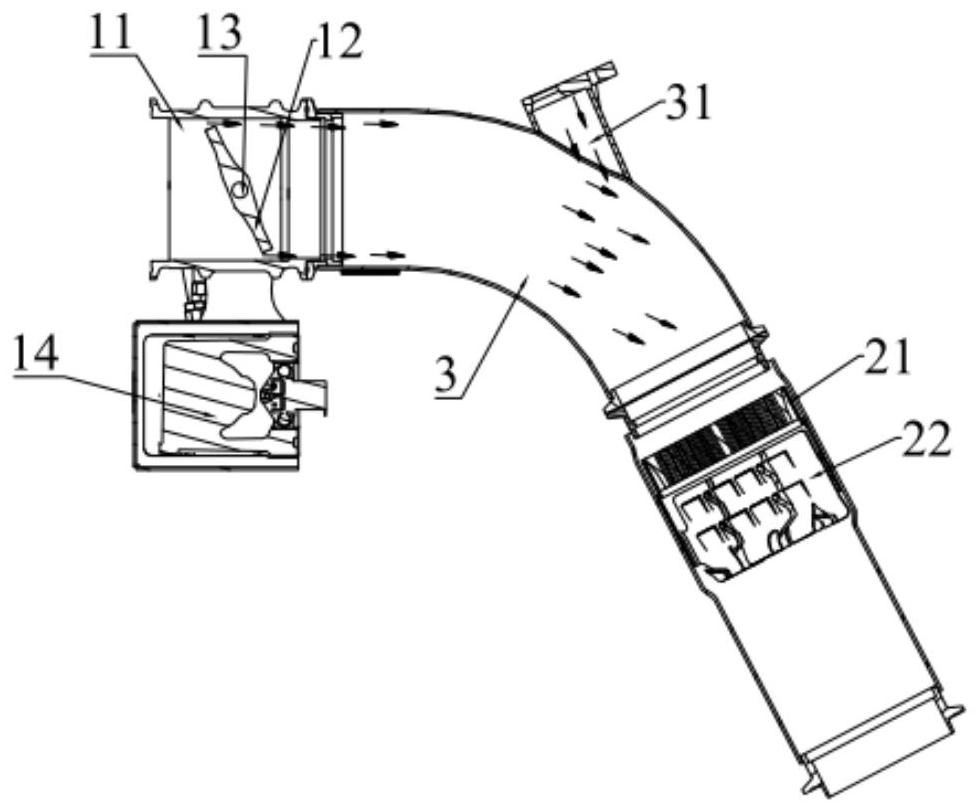

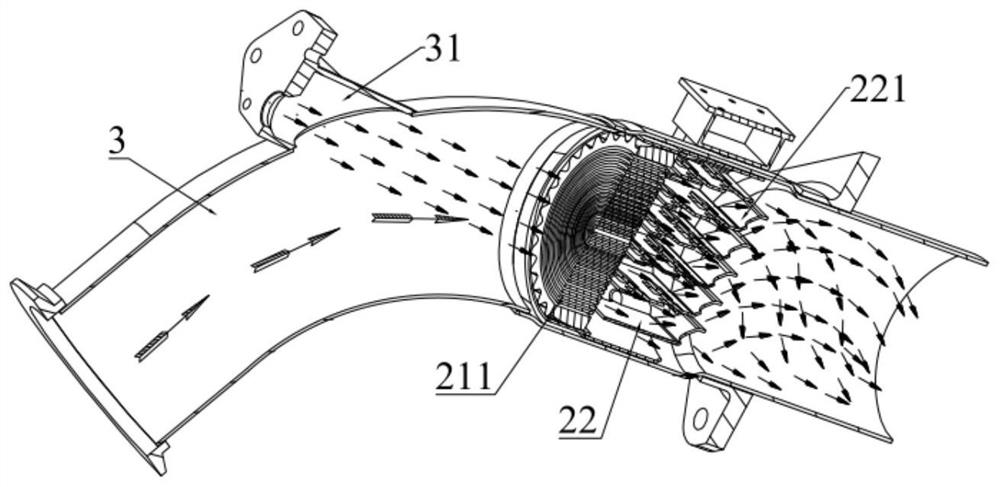

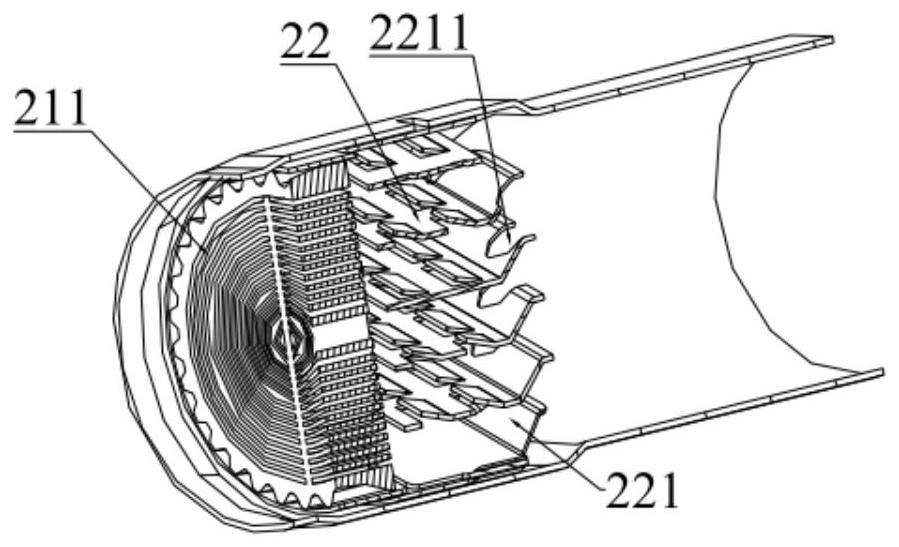

[0036] The embodiment of the invention discloses a mixer integrated device, such as Figure 1-Figure 4 As shown, the mixer integrated device includes an exhaust temperature management valve 1 and a mixing assembly 2 , and the mixing assembly 2 is arranged downstream of the exhaust temperature management valve 1 . Specifically, the exhaust temperature management valve 1 includes a valve body 11, a valve plate 12 and a driving member 14. The valve plate 12 is rotatably arranged in the valve body 11, and a gap for gas to pass is formed between the valve plate 12 and the valve body 11. The driving member The output end of 14 is in drive connection with the valve plate 12 to drive the valve plate 12 to rotate to a preset position. The mixing assembly 2 is configured to mix gas and fuel.

[0037] A mixer integrated device disclosed in the present invention can reduce the flow rate of gas by setting the valve plate 12 and turning the valve plate 12 to a preset position (preset openi...

Embodiment 2

[0060] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0061] Compared with the first embodiment, the integrated mixer device provided by this embodiment has the following difference: the preset position includes a first position and a second position, and the valve plate 12 reciprocates between the first position and the second position. According to this setting, the adjustment of the opening degree is realized through the reciprocating movement of the valve plate 12, which can disturb the air flow, improve the mixing uniformity of gas and fuel and the ability to resist steady-state crystallization. The first position may be a position where the valve plate 12 is closed, and the second position may be a position where the valve plate 12 is fully opened, and the valve plate 12 disturbs flow through continuous opening and closing movement. It should be noted that thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com