A heat supply intelligent management system and its working method

A technology of intelligent management system and working method, which is applied in the field of heating intelligent management system, can solve the problems that are difficult to eliminate, affect the superiority of central heating, and the mismatch between heat supply and heat demand, so as to reduce heat energy loss and waste, The effect of improving heat supply guarantee capacity and improving operation and management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

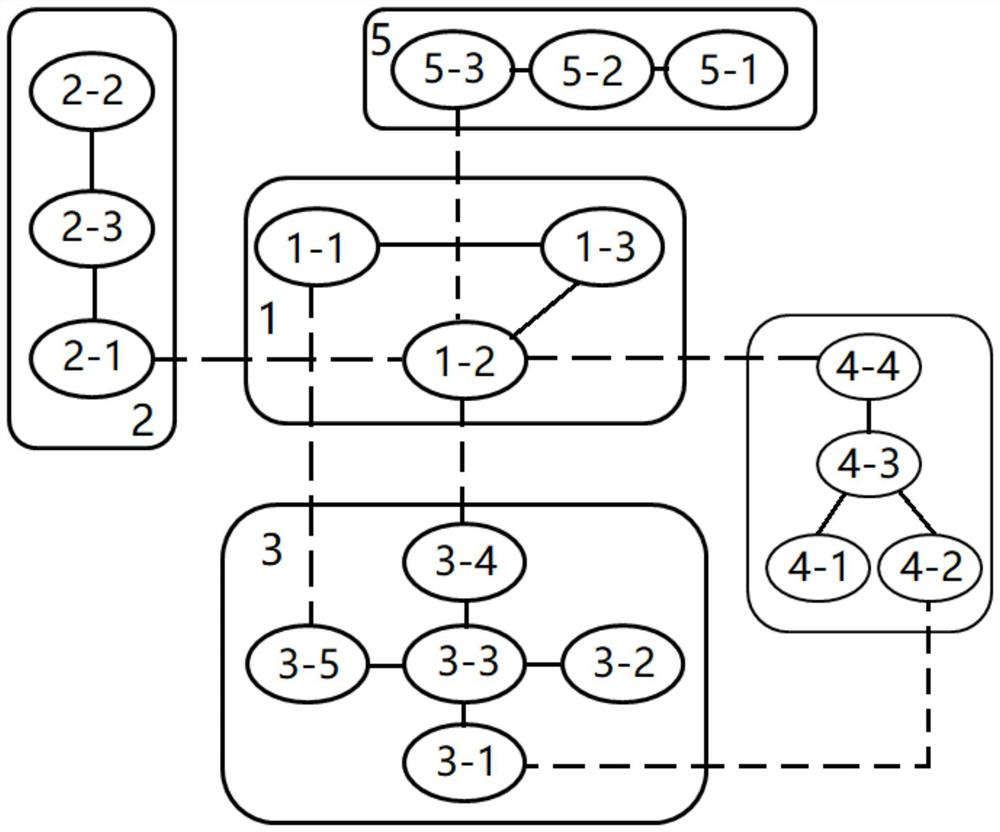

[0040] like figure 1 , is the heating intelligent management system of the present invention, including a central control system 1 , a heating network monitoring system 2 , a heat metering system 3 , a customer service and charging system 4 and a video monitoring system 5 .

[0041] The heating network monitoring system 2 includes a heating network database module 2-1, a heating network monitoring measuring point 2-2 and a heating network data processing module 2-3; the heating network data processing module 2-3 will come from the heating network monitoring measuring point 2-2 After the heat network data is processed, it is stored in the heat network database module 2-1.

[0042] Heat user metering and monitoring system 3 includes heat meter 3-1, room temperature measuring point 3-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com