Camera Optical Lens

An optical lens and lens technology, applied in the field of optical lenses, can solve the problems of unreasonable setting of long focal length, ultra-thinning, focal power, lens spacing and lens shape, etc., and achieve the effect of excellent optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

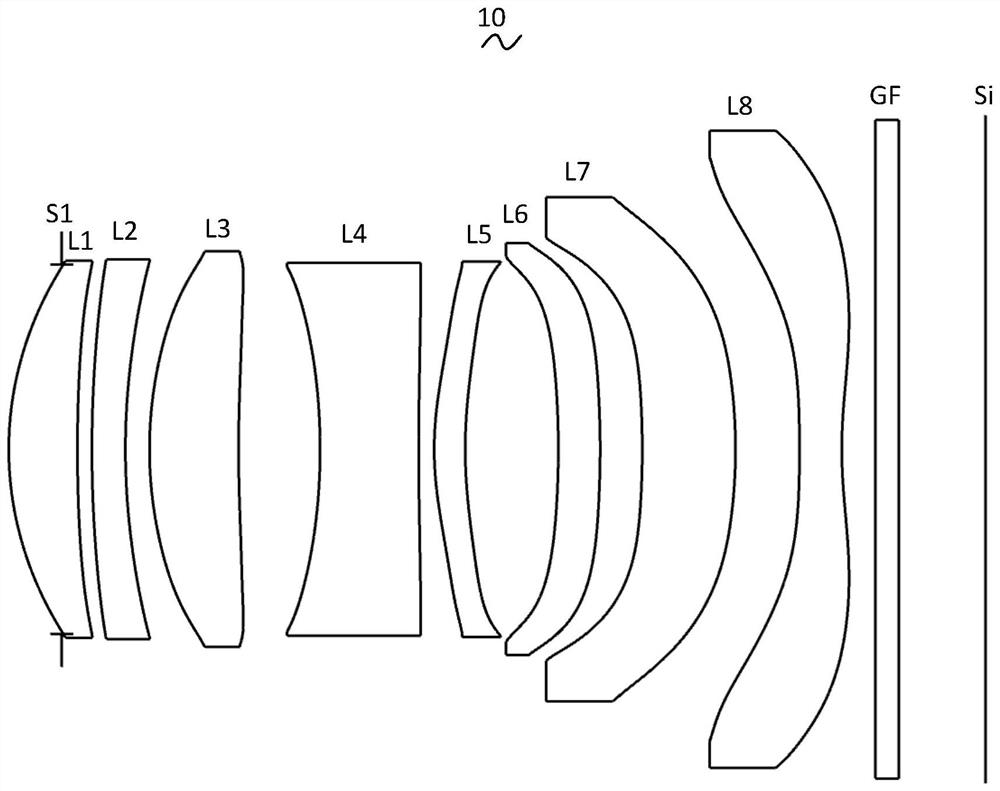

[0032] Referring to the accompanying drawings, the present invention provides an imaging optical lens 10. FIG. 1 shows the first embodiment of the present invention.

[0036] 0.95≤f / TTL; (1)

[0038] 0.25≤(R15+R16) / (R15-R16)≤0.90. (3)

[0043] In this embodiment, the object side surface of the first lens L1 is a convex surface at the paraxial position, and the image side surface is a concave surface at the paraxial position.

[0047] In this embodiment, the object side surface of the second lens L2 is a convex surface at the paraxial position, and the image side surface is a concave surface at the paraxial position.

[0050] In this embodiment, the object side surface of the third lens L3 is a convex surface at the paraxial position, and the image side surface is a concave surface at the paraxial position.

[0054] In this embodiment, the object side of the fourth lens L4 is concave at the paraxial position, and the image side is concave at the paraxial position.

[0058] In this...

no. 2 approach

[0154] FIG. 5 is a schematic structural diagram of an imaging optical lens 20 according to a second embodiment of the present invention. Sixth lens L6

[0155] Tables 5 and 6 show design data of the imaging optical lens 20 according to the second embodiment of the present invention.

[0157]

[0158]

[0159] Table 6 shows aspheric surface data of each lens in the imaging optical lens 20 according to the second embodiment of the present invention.

[0161]

[0164]

[0166]

[0168] As shown in Table 13, the second embodiment satisfies each conditional expression.

no. 3 approach

[0172] FIG. 9 is a schematic diagram showing the structure of the imaging optical lens 30 according to the third embodiment of the present invention.

[0173] Tables 9 and 10 show design data of the imaging optical lens 30 according to the third embodiment of the present invention.

[0175]

[0176]

[0177] Table 10 shows aspheric surface data of each lens in the imaging optical lens 30 according to the third embodiment of the present invention.

[0179]

[0180]

[0183]

[0185]

[0186]

[0188] The following Table 13 lists the numerical values corresponding to each conditional expression in this embodiment according to the above-mentioned conditional expression. Obviously, the actual

[0191]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com