Microscopic imaging assembly, device and system adopting array type objective lens and imaging method

A technology of microscopic imaging and imaging methods, applied in microscopes, optical components, optics, etc., can solve the problems of limited observation area size and poor observation timeliness of microscopic systems, and achieve the effect of overcoming a large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

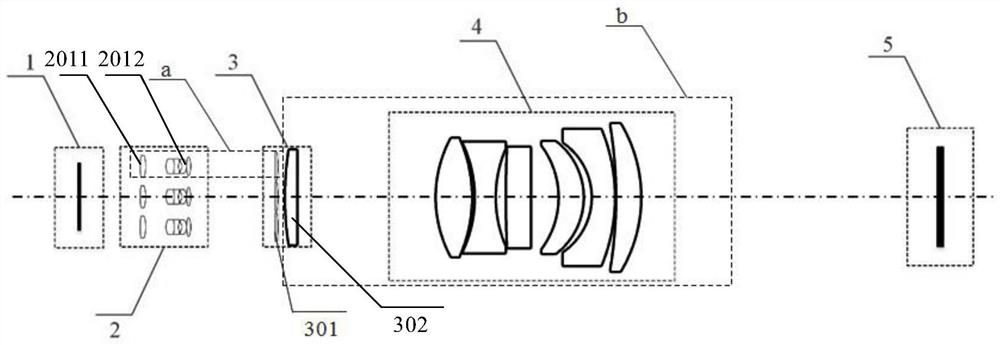

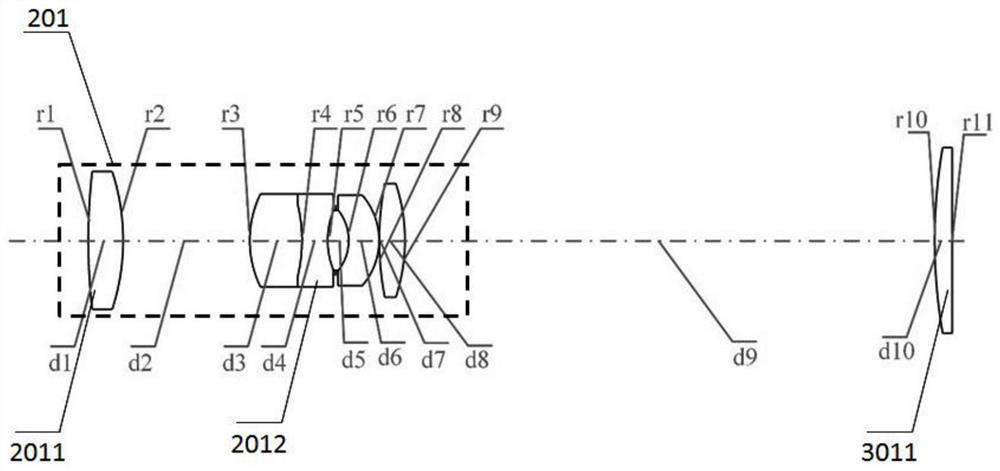

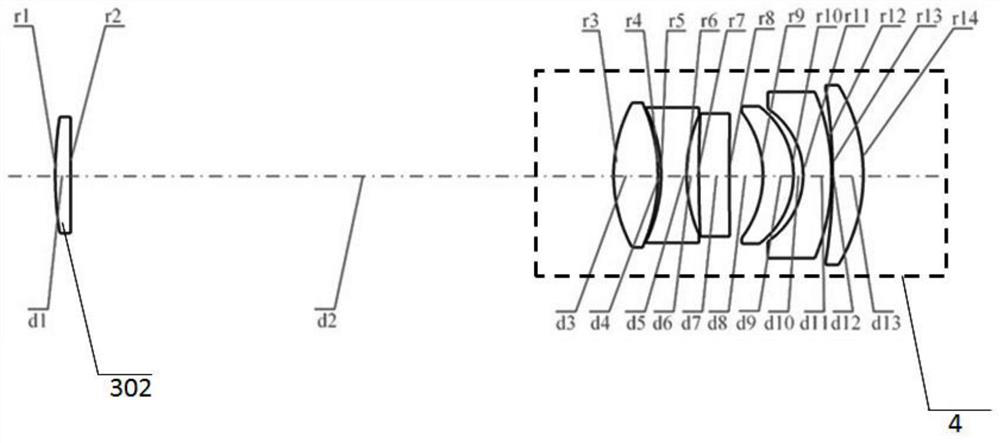

[0059] A microscopic imaging system using an arrayed objective lens, such as Figures 1 to 3 As shown, it includes an objective lens array 2 (array imaging objective lens), a field lens combination 3 (double field lens assembly), a secondary compensation magnification lens group 4 (near field image transmission mirror) and a detector arranged in sequence along the light transmission direction 6 (electronics focal plane detector, image sensor, commercial detector of 5-10 micron pixel resolving power); Described objective lens array 2 comprises 3 * 3 objective lens units 201 (that is 9 Near-field low-magnification objective lens units 201 with consistent parameters are arranged in a nine-square grid); each objective lens unit 201 includes a first objective lens 2011 and a primary magnification lens group 2012 arranged in sequence along the light transmission direction; the field lens combination 3 includes In the transmission direction, a first field lens array 301 and a second ...

Embodiment 2

[0074] The difference with embodiment 1 only lies in:

[0075] In step 2) of the imaging method, the control of the translation of the sample slide in the object plane 1 by the two-dimensional translation stage is replaced by the control of the imaging system to perform three translations in the plane perpendicular to the optical axis.

Embodiment 3

[0077] The difference with embodiment 1 only lies in:

[0078] Such as Figure 6 As shown, one detector 6 at the image plane 5 of the imaging system is replaced with 3×3 detectors 6 arranged coplanarly in an array and corresponding to 3×3 objective lens units 201 one-to-one. In imaging, Each detector can effectively overcome the image plane curvature (field curvature) effect caused by the large field of view hybrid optical axis imaging system through small adjustments of tilt and working distance, and further obtain high-resolution imaging results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com