Rolling mill main transmission system output feedback control method considering input limitation

A main transmission system and output feedback technology, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as closed-loop system instability, motor failure, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

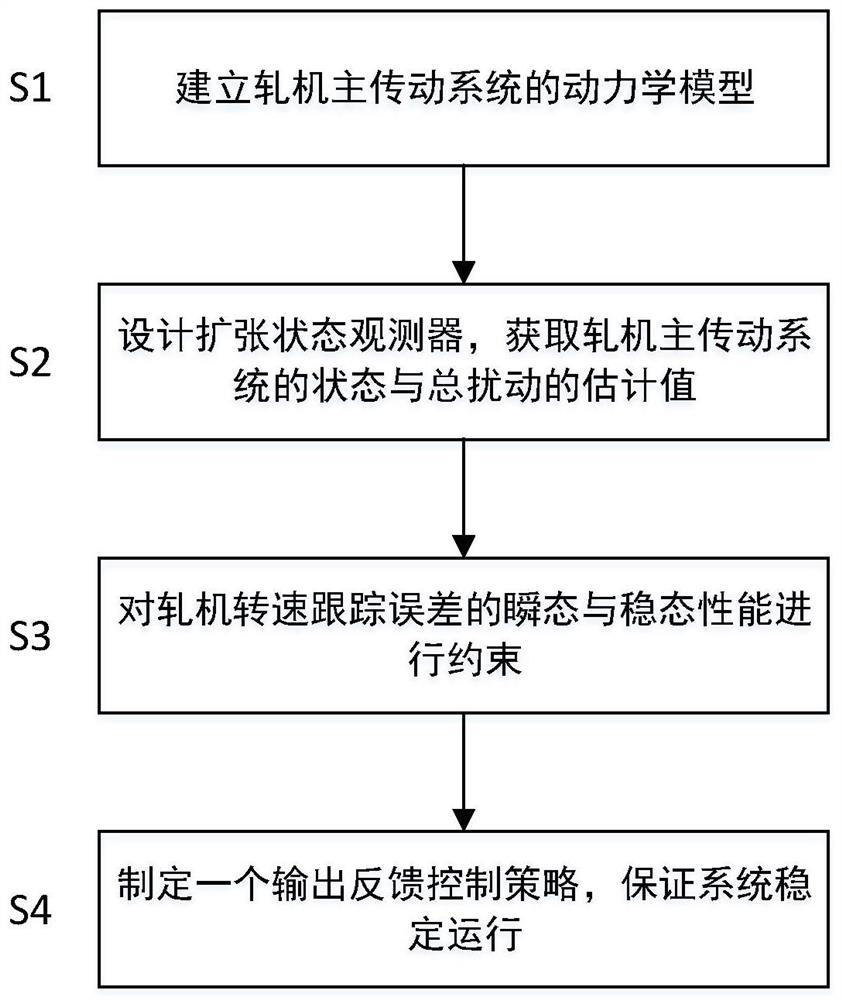

[0049] The output feedback control method of the rolling mill main drive system considering the input limitation of this embodiment includes the following steps:

[0050] S1. Considering the impact of unmodeled dynamics, external unknown disturbances, nonlinear factors and input saturation on the system, establish a dynamic model of the main drive system of the rolling mill;

[0051]

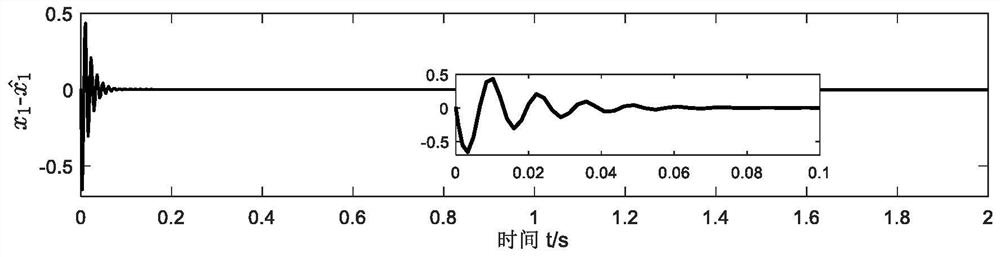

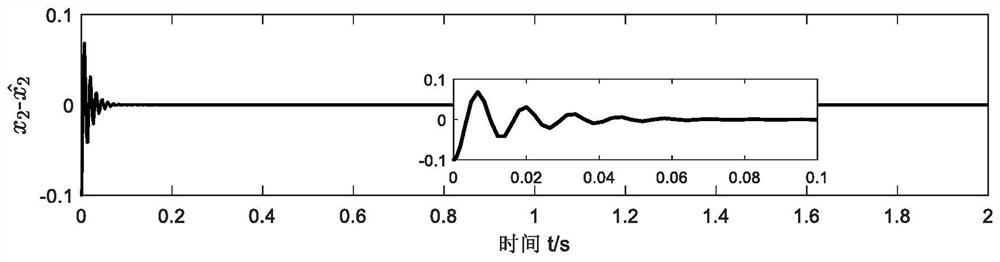

[0052] Among them, J 1 is the moment of inertia of the motor end; J 2 is the moment of inertia of the roll end; θ 1 (t) is the rotation angle of the motor; for θ 1 The first derivative of (t), that is, the speed of the motor; for θ 1 The second derivative of (t), that is, the angular acceleration of the motor; θ 2 (t) is the angle of rotation of the roll; for θ 2 The first derivative of (t), that is, the rotational speed of the roll; for θ 2 The second derivative of (t), tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com