Cast hollow blade wall thickness control method based on mold core self-adaptive positioning

A hollow blade and control method technology, applied in cores, casting molding equipment, casting molds, etc., can solve the problems of inability to meet the requirements of aero-engine test and assessment, long cycle, large capital investment, etc., to shorten the mold iteration cycle, improve Qualification rate, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

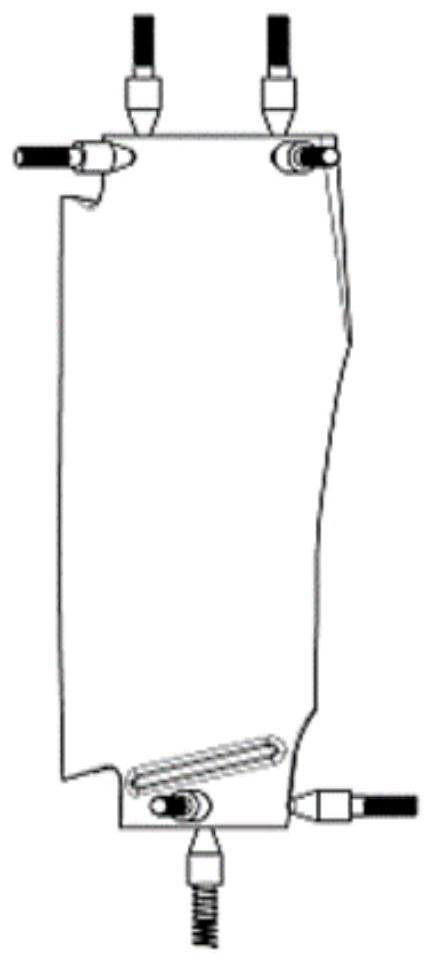

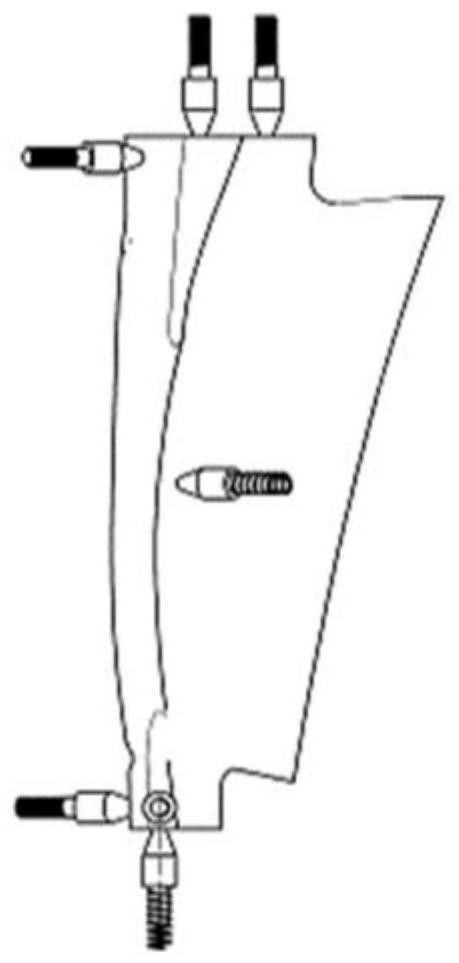

[0028] Taking a typical turbine guide vane as the verification object, the distribution of 6 positioning points and 2 pressing points selected to maintain the posture of the ceramic core in the wax mold compression mold is shown in figure 1 and figure 2 .

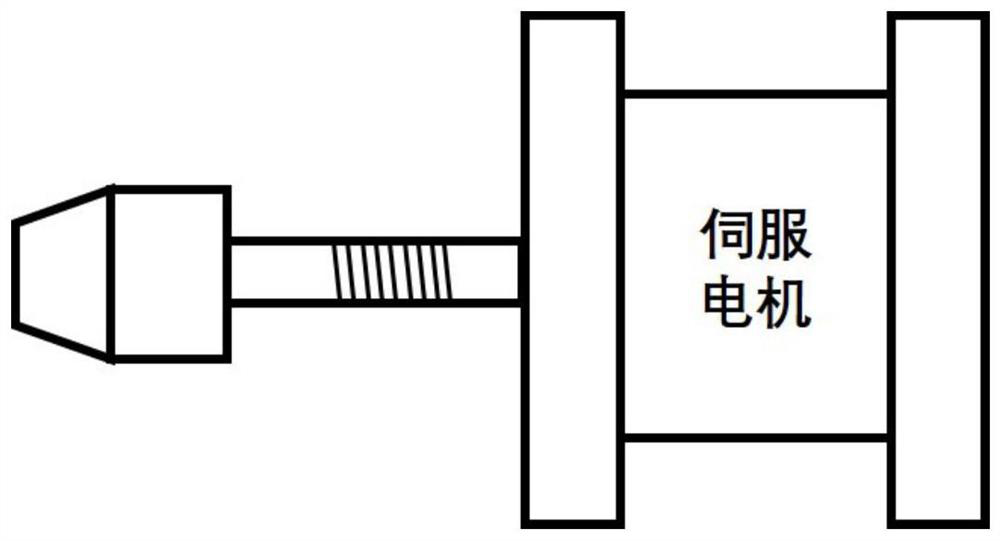

[0029] At the positioning point, there is a positioning boss that is driven by a motor to rotate and adjust the height. The design structure is shown in image 3 , including the front section, middle section, rear section and pins with external threads. Among them, the radius of the upper bottom of the front section is 2mm, the radius of the lower bottom is 4mm, the height is the same as the local theoretical wall thickness at the positioning point, and the circumferential edges of the upper bottom surface of the circular table are rounded; the middle section of the boss is cylindrical, the bottom surface radius is 4mm, and the height is 10mm; The back section of the boss is cylindrical, the radius of the bottom surface ...

Embodiment 2

[0038] Taking a typical turbine working blade as the verification object, the distribution positions of the 6 positioning points and 2 pressing points selected to maintain the posture of the ceramic core in the wax mold are shown in Figure 8 and Figure 9 .

[0039] At the positioning point, there is a positioning boss that is driven by a motor to rotate and adjust the height. The design structure is shown in image 3 , including the front section, middle section, rear section and pins with external threads. Among them, the radius of the upper bottom of the front section is 1mm, the radius of the lower bottom is 2mm, the height is the same as the local theoretical wall thickness at the positioning point, and the circumferential edges of the upper bottom of the circular platform are rounded; the middle section of the convex platform is cylindrical, the radius of the bottom surface is 2mm, and the height is 3mm; The back section of the boss is cylindrical, the radius of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com