Numerical control machine tool and its control method and device for adaptive machining

A technology of numerical control machine tools and control methods, applied in digital control, program control, electrical program control, etc., can solve the problem that the feed rate cannot maintain the cutting state, and achieve the effect of improving efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

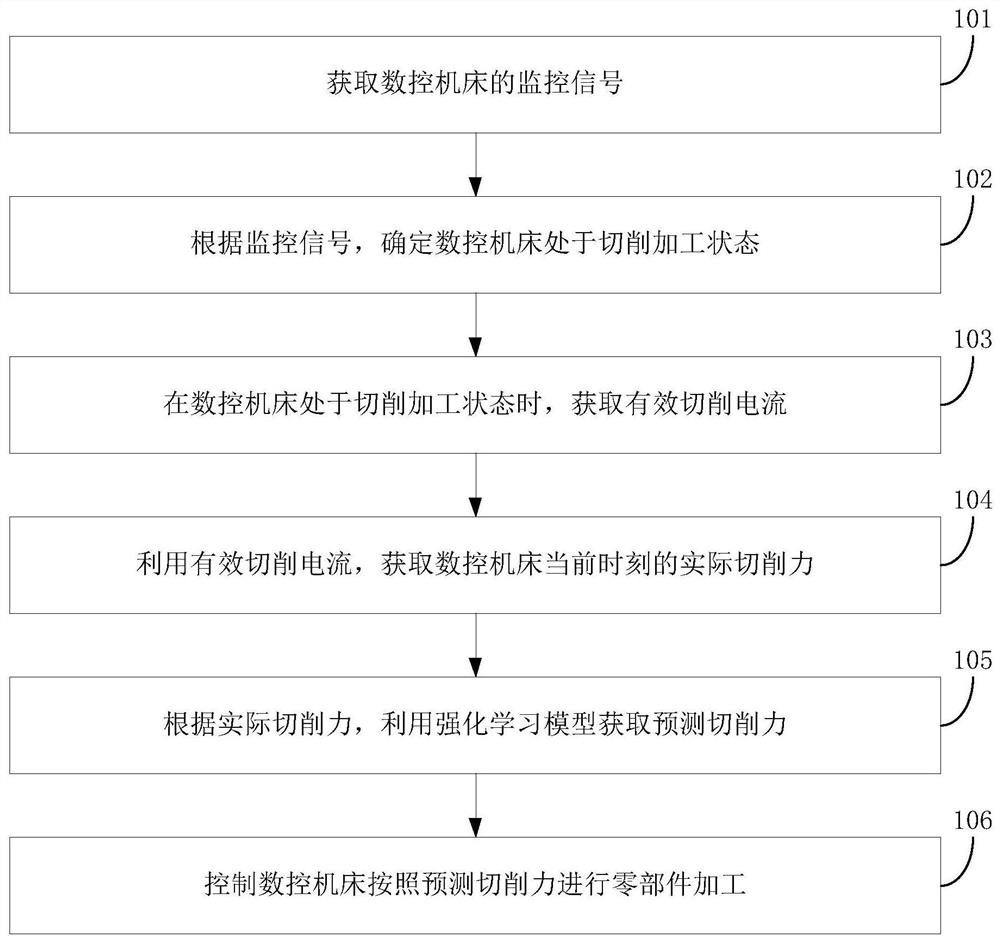

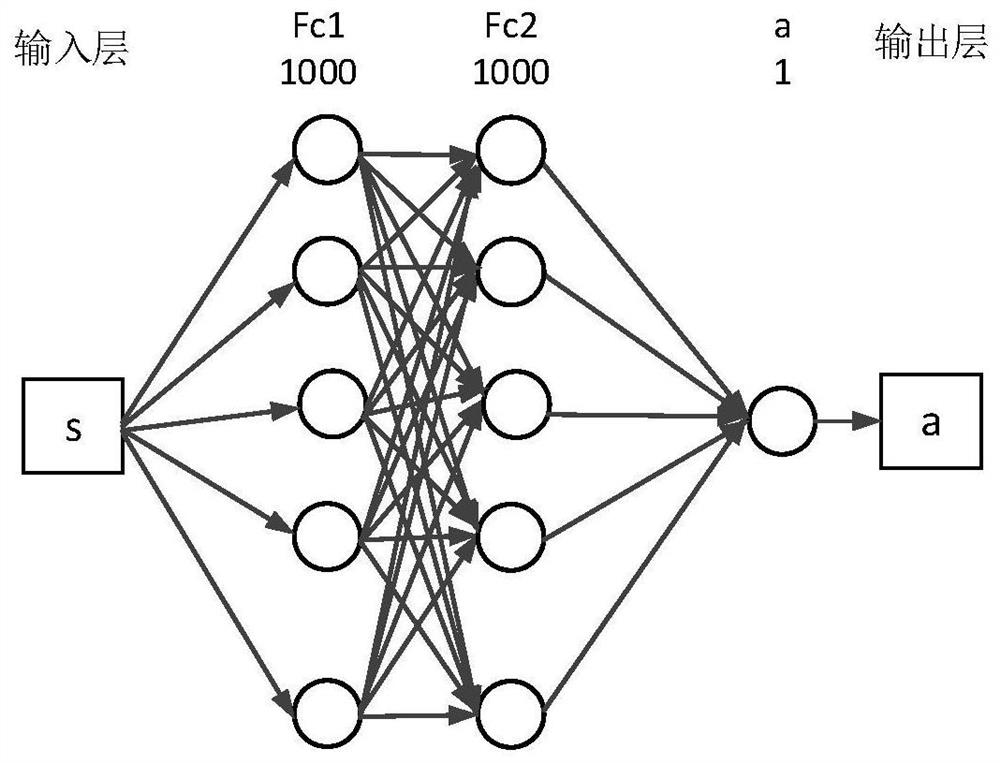

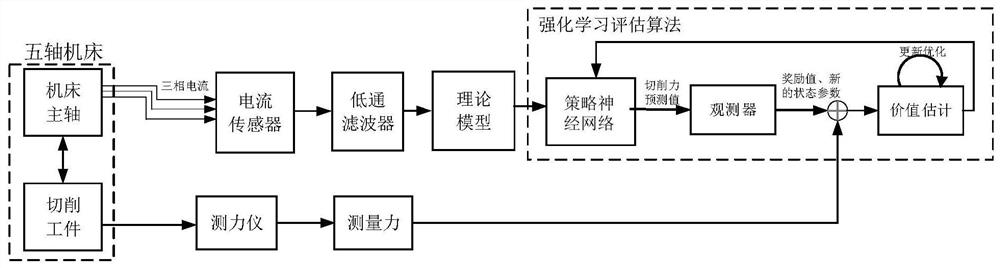

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0025] Complex parts, especially blade parts, are important components in aerospace and other industries. They have complex curved surfaces, numerous parameters, and complex processing and manufacturing. Its processing rigidity is low and it is easy to deform, and the accuracy of shape tolerance is high. The materials are mainly titanium alloys, high-temperature alloys and other difficult-to-machine materials, which makes it difficult to process parts. Therefore, how to reduce machining deformation and control precision in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com